; If an incorrect spark plug is installed in a BR 600, the engine may quit after it warms

up, or it may run poorly. It may also try to run-on when the ignition is switched off.

;

Set the gap on all STIHL spark plugs at twenty thousands of an inch.

;

The final verification of a faulty ignition module may have to be done by replacing it

with a known good ignition module for comparison.

FS 90, FS 100, FS 110,

KM 110, FC 100, FC 110,

HT 100, HT 101 , HL 100

FS 130, KM 130,

HT 130, HT 131

BR 500, BR 550, BR 600

STIHL 0000 400 7009

Bosch USR7AC

NGK CMR5H

STIHL 0000 400 7011

NGK CMR6H

Refer to the STIHL repair specification charts for other models.

Air Filters

Air filters should be inspected and cleaned regularly. Filters should be replaced at least

once a year, or more often if needed.

;

The air filter element used on the 4-MIX® shaft mounted engines should never be

cleaned in solvent. Brush off any loose debris and clean it with compressed air.

;

STIHL backpack blower engines use a pleated paper air filter. The only way to

service it is to brush off any debris or gently blow it off. Do not use high pressure

air or the pleats may tear.

;

Always inspect the clean side of the filter housing for any evidence of dirt or grit. If

dirt is present, the filter needs to be serviced more often.

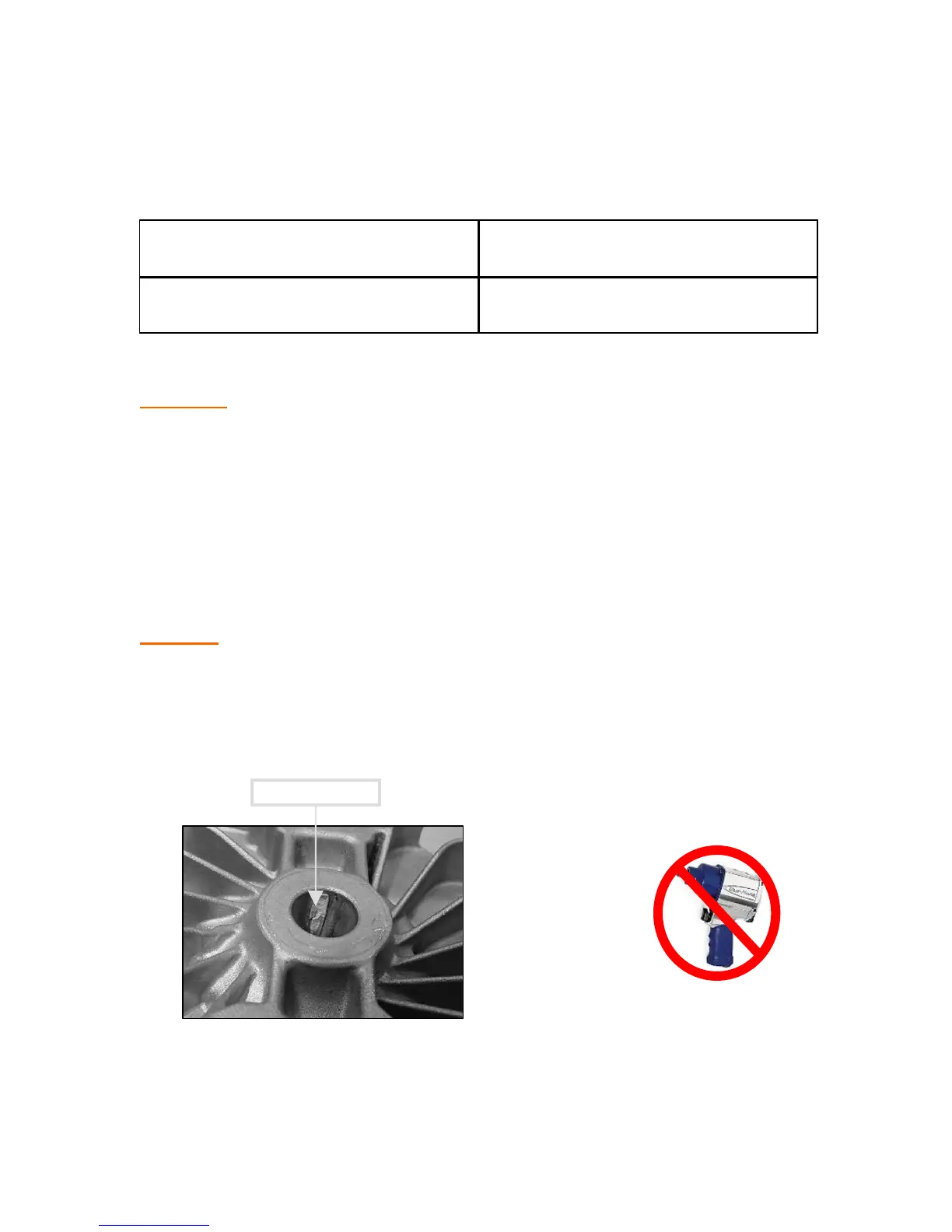

Flywheel

Fault – A sheared flywheel key.

;

Occurs when: The nut is not properly tightened, or if an impact wrench is used to

loosen or tighten the fan wheel, flywheel, clutch, or starter cup nut.

;

A sheared key may not cause the ignition module to lose spark, so the spark tester

will not show a fault.

Never use an

impact wrench

on any STIHL

product!

Verify flywheel timing.

Loading...

Loading...