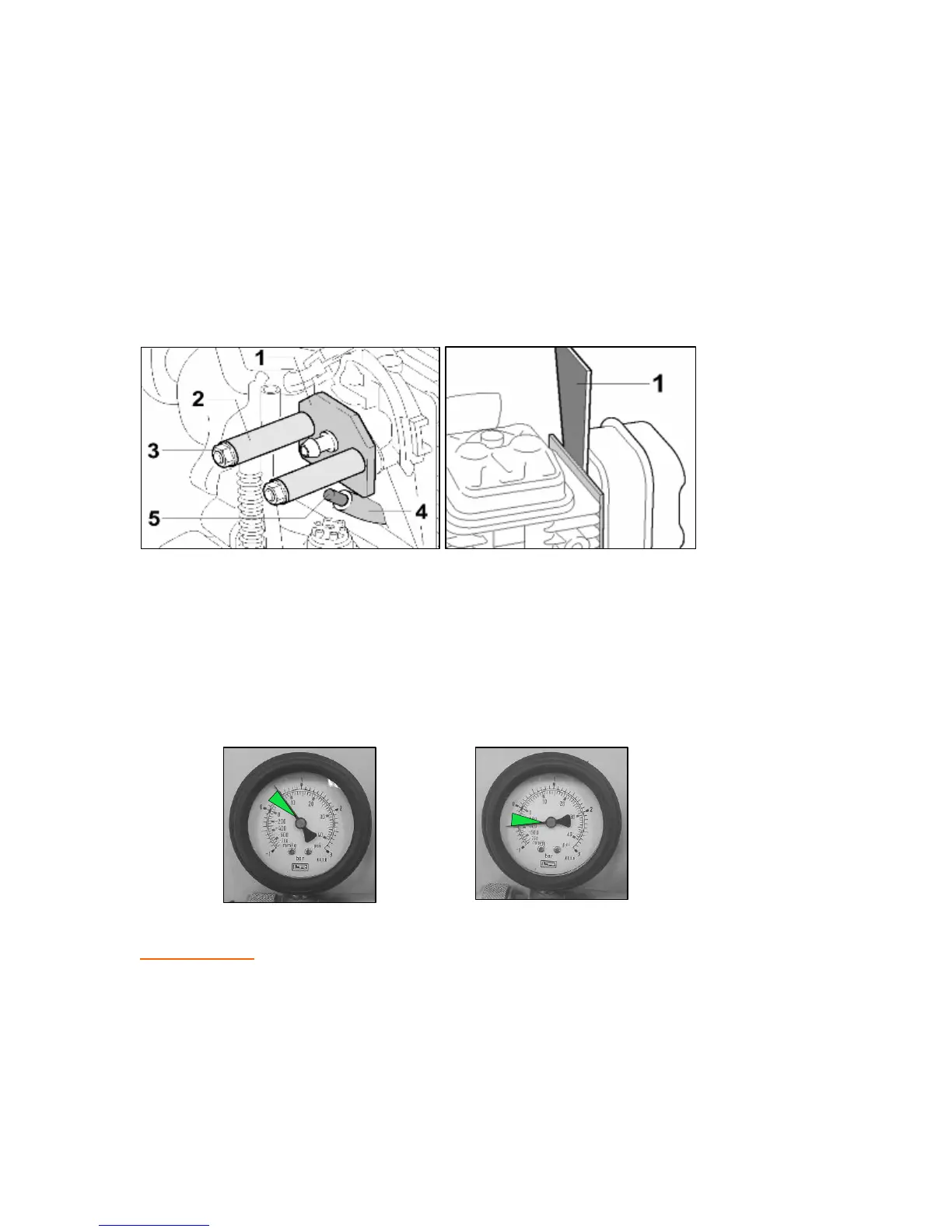

; Install the rubber block off plate between the muffler gasket and the engine and

install a flange adapter in place of the carburetor. Be sure to block the impulse

hose.

;

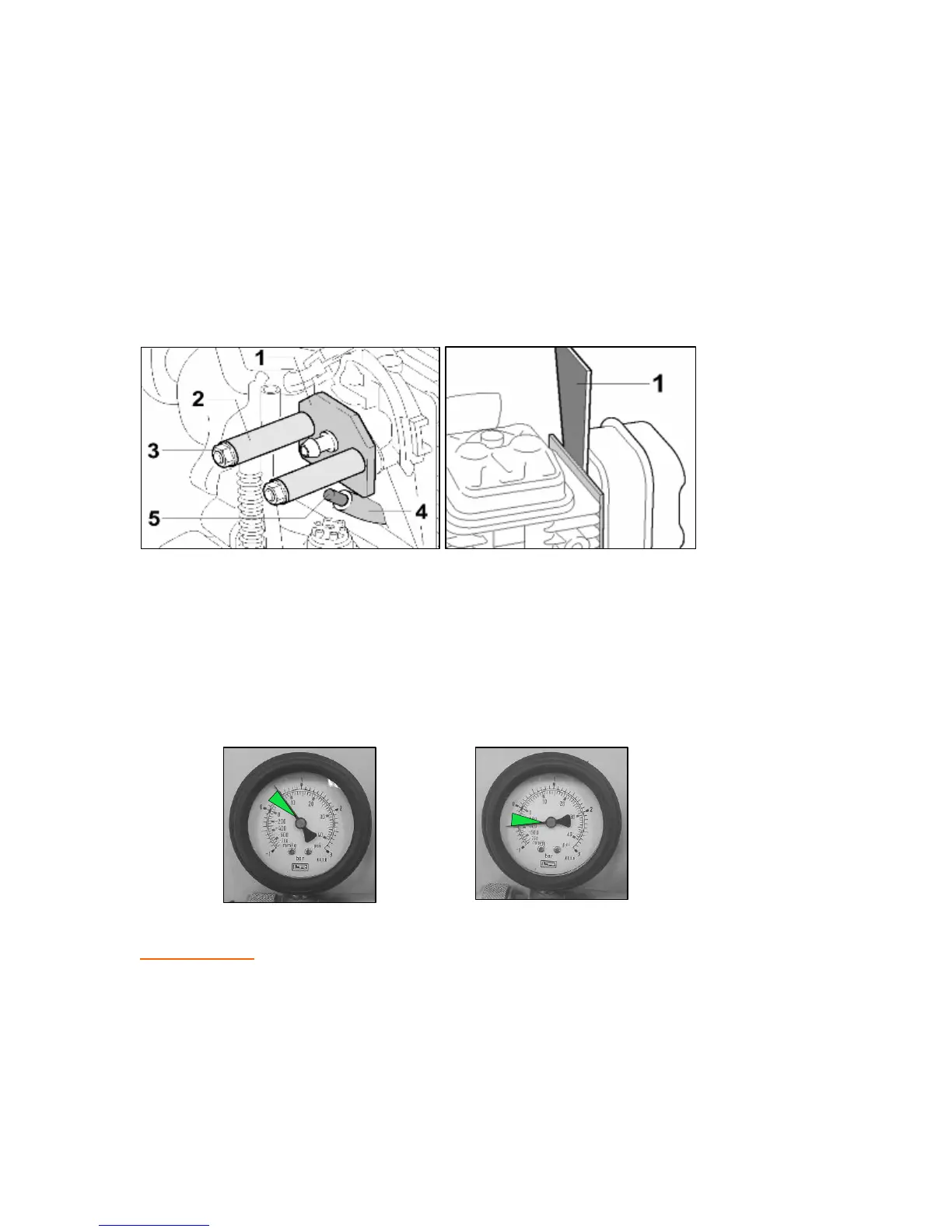

When checking the crankcase for leaks, pressurize the crankcase to a reading of

positive 0.5 bar, or about 7 pounds per square inch. The pressure should not leak

down to positive 0.3 bar, or about 4 pounds per square inch, in 20 seconds. If it will

not hold pressure or leaks down too fast, locate the leak with a soapy water

solution.

To perform a crankcase pressure and vacuum test the intake port and exhaust port must

be sealed with the proper blocking tools. STIHL 4-MIX® engines need to also have the

valve cover installed.

Gauge readings.

;

If the crankcase holds pressure, then apply a vacuum of negative 0.5 bar, or about

negative 7 pounds per square inch. The vacuum reading should not leak to above

negative 0.3 bar, or about negative 4 pounds per square inch, in 20 seconds.

;

If the engine has a vacuum leak, but no pressure leak, the fault is most likely a

crankshaft seal. Expose each seal and position the engine with the seal facing up,

spray some light penetrating lubricant on the seal around the crankshaft and apply

a vacuum with the tester to see if any of the liquid is sucked into the seal.

Vacuum

Range

Pressure

Range

Impulse Line

Check impulse line for blockage.

;

One method to check the impulse is to use a small carburetor pressure tester, and

hook it to the impulse hose.

;

When you pull the starter rope, the needle on the gauge should bounce back and

forth indicating positive and negative pressure. If nothing happens, the impulse

line or impulse passageway is restricted.

Loading...

Loading...