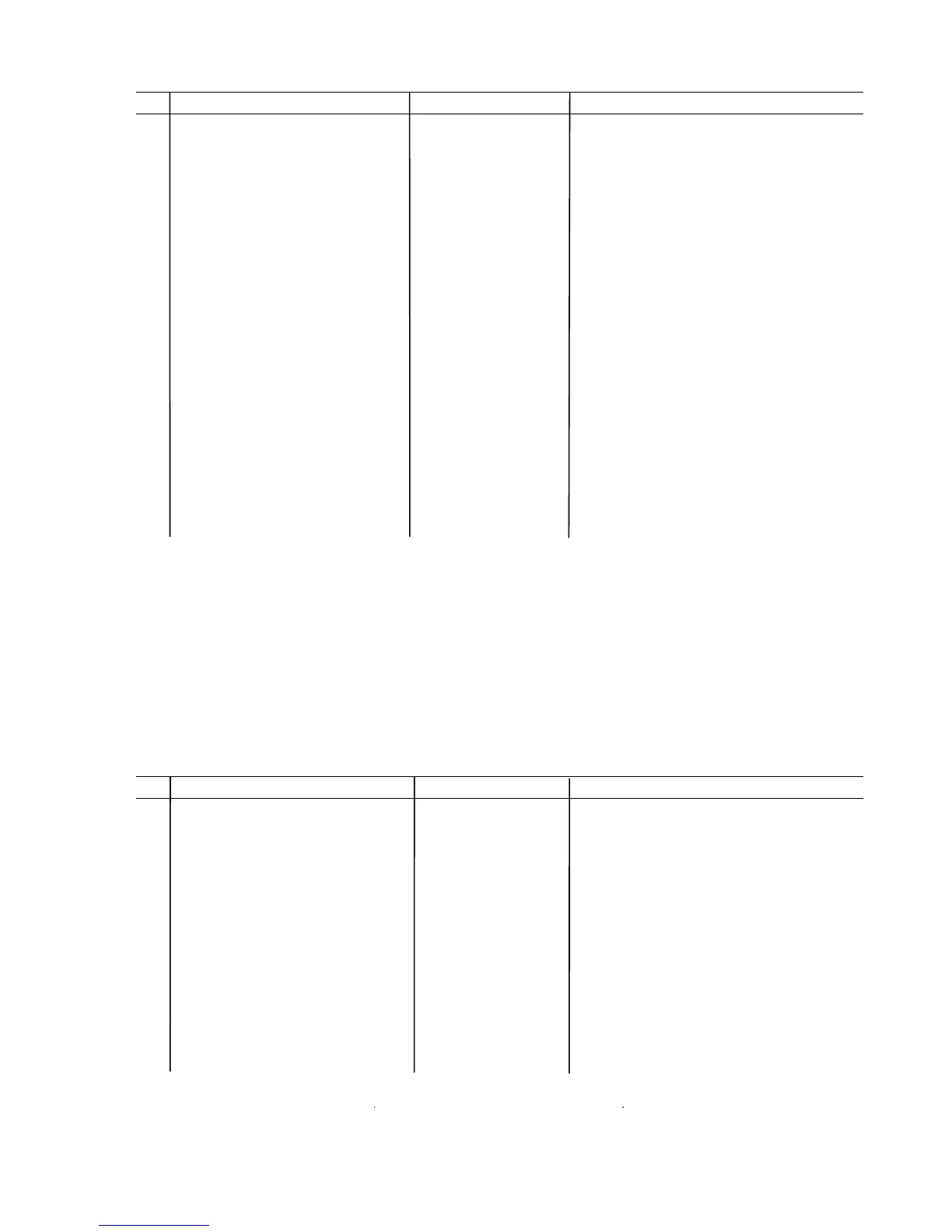

10. Special Servicing Tools and Aids

10.1 Special Servicing Tools

No. Part Name Part No. Application Rem.

1Assemblytube 11178900900 Attachingsprings

2ScrewdriverT20x100 59108902301 ReleasingISscrews 1)

3SplinescrewsocketT20x120 08125422041 TighteningISscrews

4T-handle screwdriver

QI-T27x150 5910 890 2400 Releasing IS screws, installing 1)

stator

5SplinescrewsocketT27x125 08125422104 TighteningISscrews

6Torquewrench 59108900301 0.5-18Nm 2)

(0.4 - 13.5 lbf.ft)

5910 890 0302 3)

7Torquewrench 59108900311 6-80Nm 2)

(4.4 - 60 lbf.ft)

5910 890 0312 3)

8Assemblystand 59108903100 Holdingsawforservicing

9Crimpingtool 59108908210 Attachingconnectorstoelectrical

wires

10 Assembly drift 1111 893 4700 Removing needle sleeve

from handle housing

11 Press arbor 4116 893 7205 Installing needle sleeve

in handle housing

Remarks:

1) On Plastoform screws, use for releasing only.

2) Always use torque wrench to tighten Plastoform screws.

3) Wrench has optical/acoustic signal.

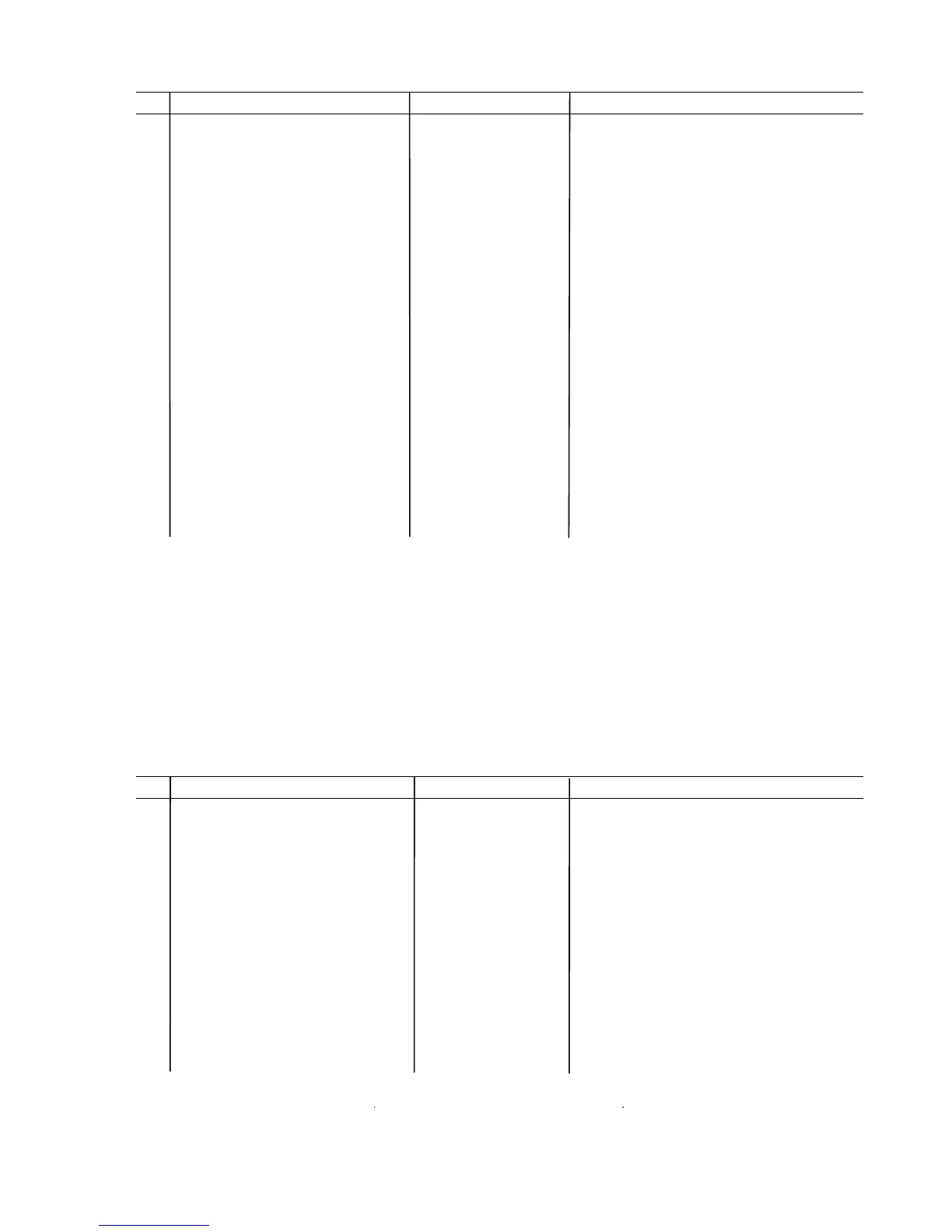

10.2 Servicing Aids

No. Part Name Part No. Application

1Medium-strengththreadlocking 07861111101 Slottednutforpinion

adhesive (Loctite 242)

2High-strengththreadlocking 07861100126 Securingbrakedrum

adhesive (Loctite 648)

3Standardcommercial, Cleaningrotorshaftstuband

solvent-based degreasant slotted nut

containing no chlorinated or

halogenated hydrocarbons

4Lubricatinggrease 07811201111 Slidingandpivotpoints,pininoilpump

5Molybdenumgrease(eg.Molykote) Pivotpointsofchainbrake

6Multipurposegrease 07811201109 Ringgearandwashers

7Electrician’srepairkit 00000071013

E140,E160,E180 23

Loading...

Loading...