15Series 4144 Powerhead

6.1.3 Pressure Test

Carry out the same preparations as

for the vacuum test, b 6.1.2

– Always carry out the vacuum test,

before the pressure test, b 6.1.2

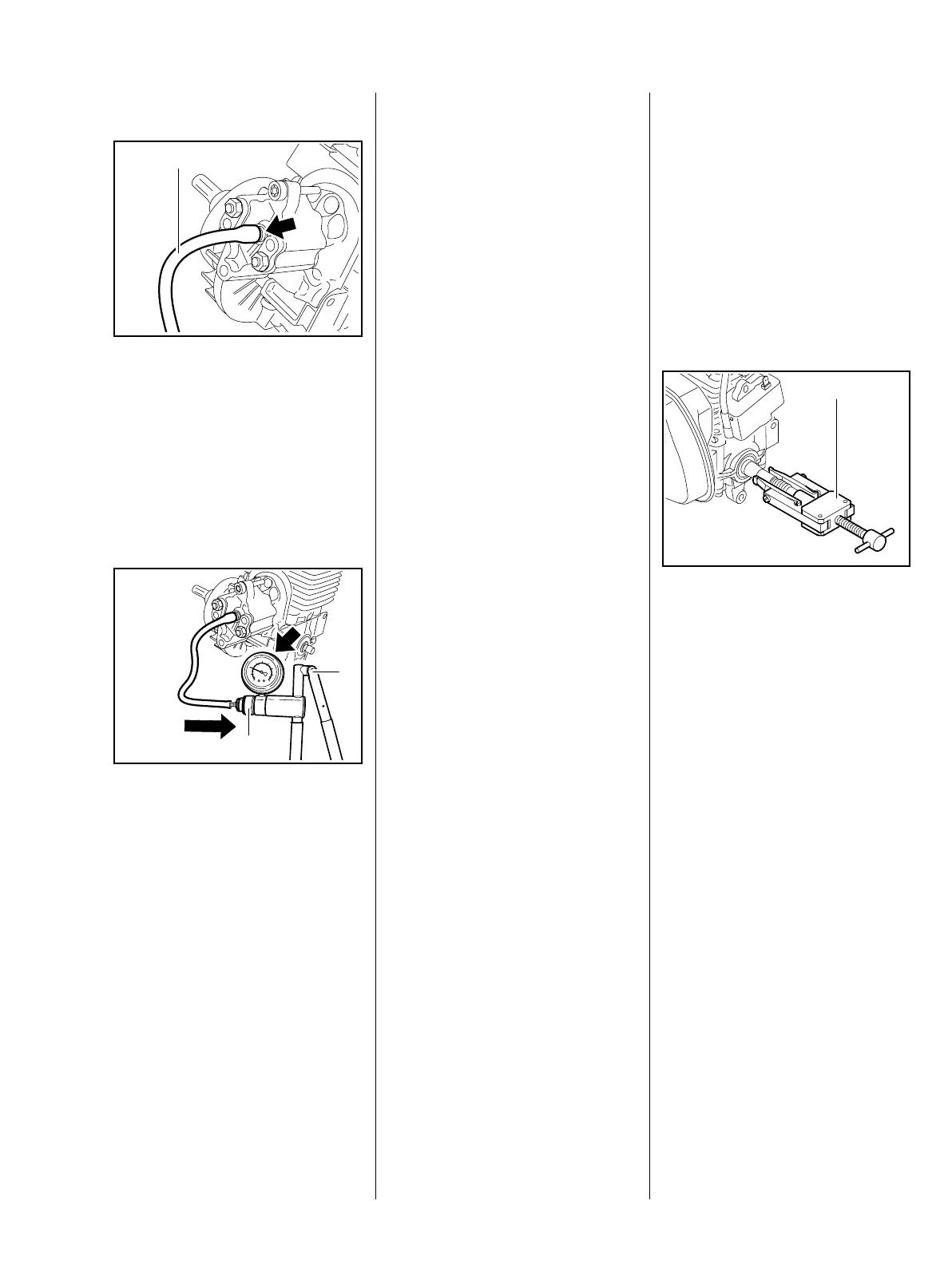

: Connect pressure hose (1) of

pump 0000 850 1300 to nipple

(arrow).

: Push ring (1) to the right.

: Operate the lever (2) until the

pressure gauge (arrow) indicates

a pressure of 0.5 bar. If this

pressure remains constant for at

least 20 seconds, the engine is

airtight.

– If the pressure drops below 0.5

bar within 20 seconds, the leak

must be located and the faulty

part replaced.

938RA020 TG

1

938RA022 TG

1

2

To find the leak, coat the suspect

area with oil and pressurize the

engine. Bubbles will appear if a leak

exists.

– After finishing the test, push the

ring to the left to vent the pump –

disconnect the hose.

– Remove the test flange.

– Install the carburetor

– see service manual for

"Series 4144 Components – FS,

FC, KM"

– Loosen the muffler and pull out

the sealing plate.

– Tighten down the muffler firmly.

– Reassemble all other parts in the

reverse sequence.

– Tightening torques, b 3.3

6.2 Oil seals

It is not necessary to disassemble

the engine to replace the oil seals.

Ignition side

– Remove the engine – see service

manual for "Series 4144

Components – FS, FC, KM"

– Remove the flywheel, b 7.5

– Free off the oil seal in its seat by

tapping it with a suitable tube or a

punch.

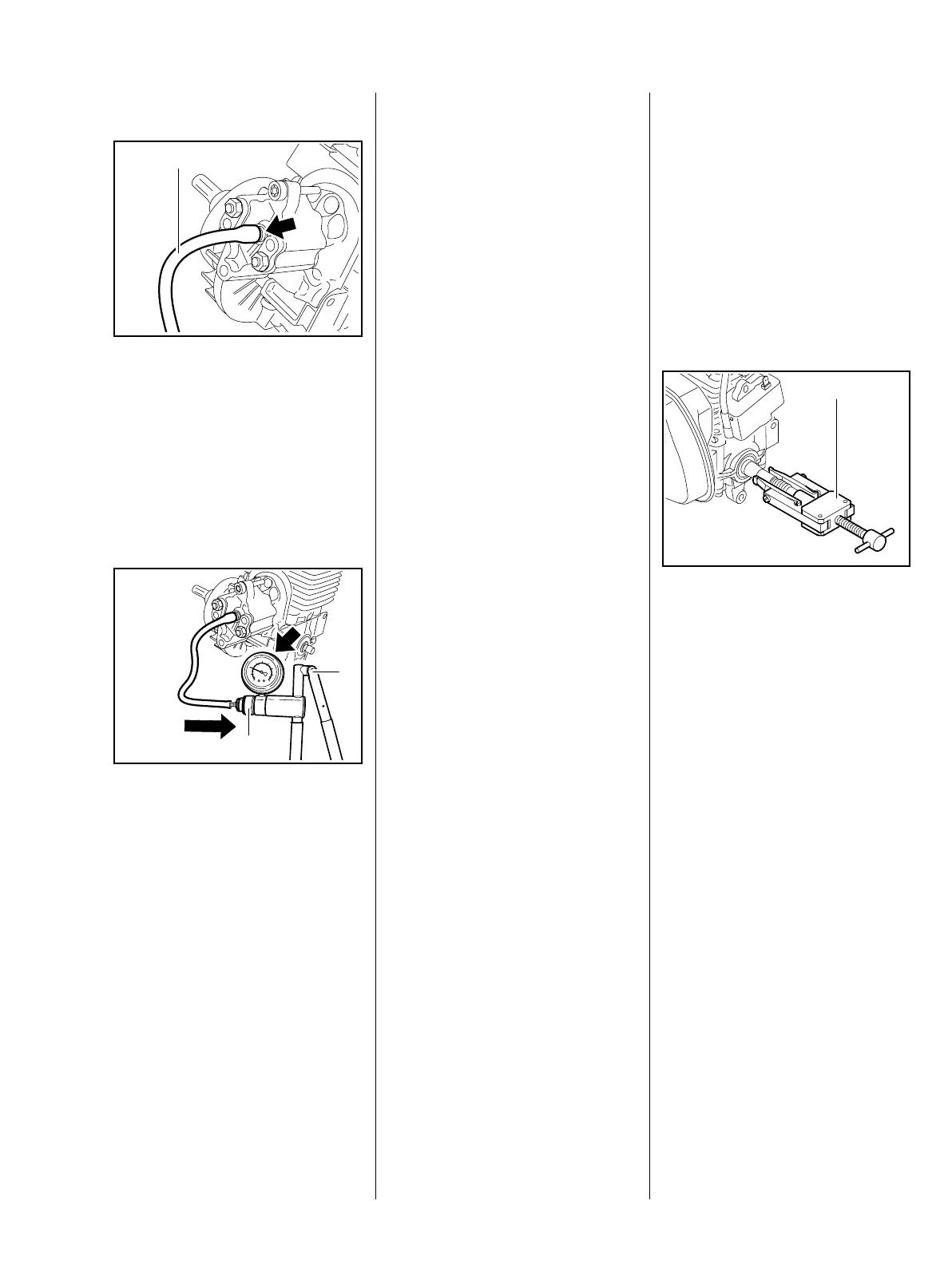

: Apply puller (1) 5910 890 4400

with No. 3.1 jaws 0000 893 3706.

– Clamp the puller arms.

– Pull out the oil seal.

Take care not to damage the

crankshaft stub.

– Clean the sealing face, b 9

– Lubricate sealing lips of new oil

seal with grease, b 9

938RA023 TG

1

Loading...

Loading...