24 Series 4144 Powerhead

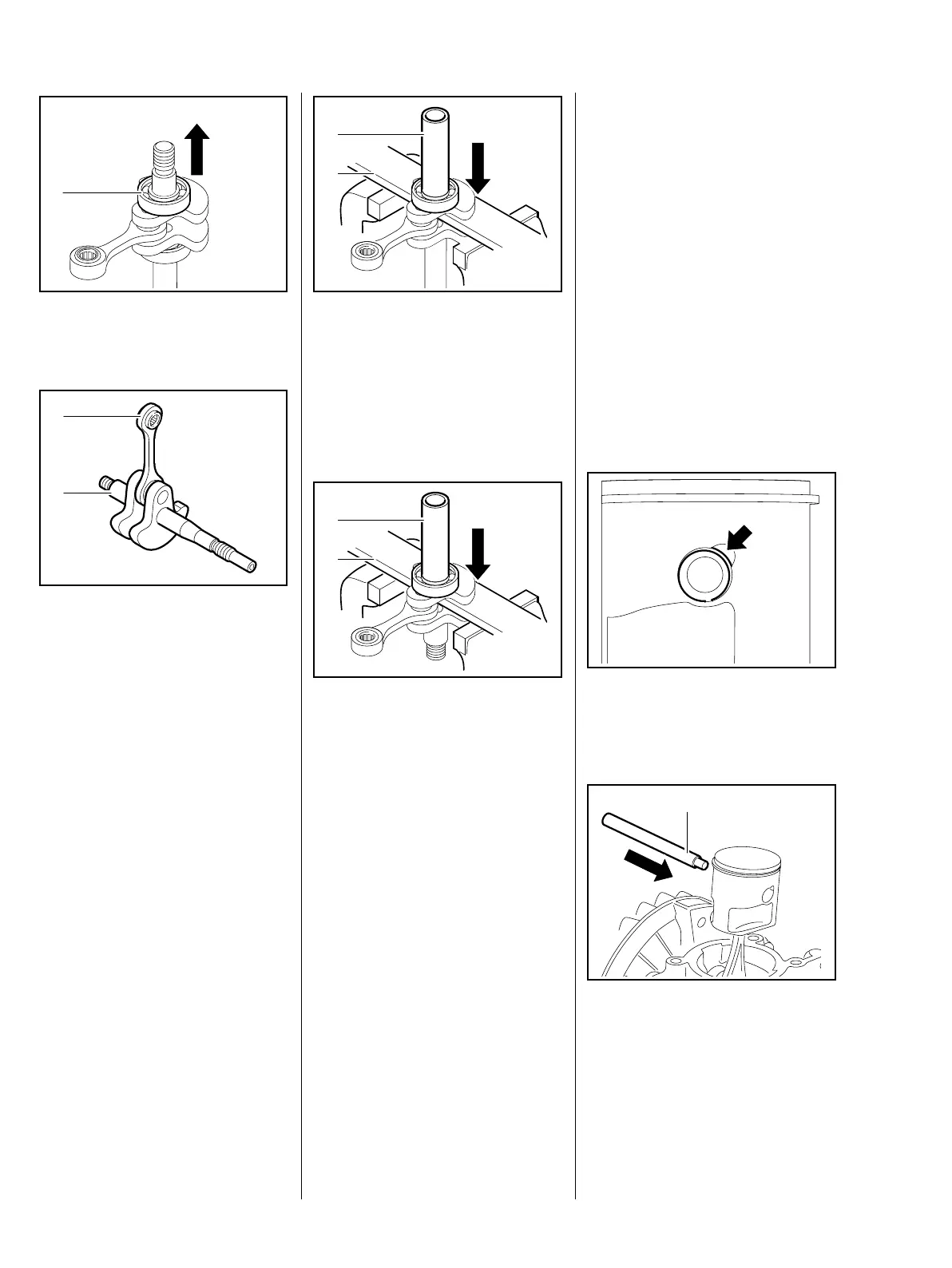

: Pull the ball bearing (1) off the

straight crankshaft stub.

The crankshaft (1), connecting rod

(2) and needle bearing form an

inseparable unit.

When fitting a replacement

crankshaft, always install new ball

bearings and oil seals.

– Before installing, clean the

crankshaft, b 9

938RA058 TG

1

1

938RA059 TG

2

Use a firm base (2) to protect the

crankshaft.

: Apply a suitable sleeve (1) to the

inner race of the ball bearing at

the carrier side and press it home

as far as stop.

Use a firm base (2) to protect the

crankshaft.

: Apply a suitable sleeve (1) to the

inner race of the ball bearing at

the ignition side and press it

home as far as stop.

– Lubricate needle bearings in

small end and on crankshaft with

oil.

– Install the piston, b 6.7

– Fit new oil seals and install the

crankshaft, b 6.5.1

– Install the engine – see service

manual for "Series 4144

Components – FS, FC, KM"

938RA060 TG

1

2

938RA061 TG

1

2

– Tightening torques, b 3.3

– Reassemble all other parts in the

reverse sequence.

6.7 Piston

– Remove the engine – see service

manual for "Series 4144

Components – FS, FC, KM"

– Remove the cylinder, b 6.4

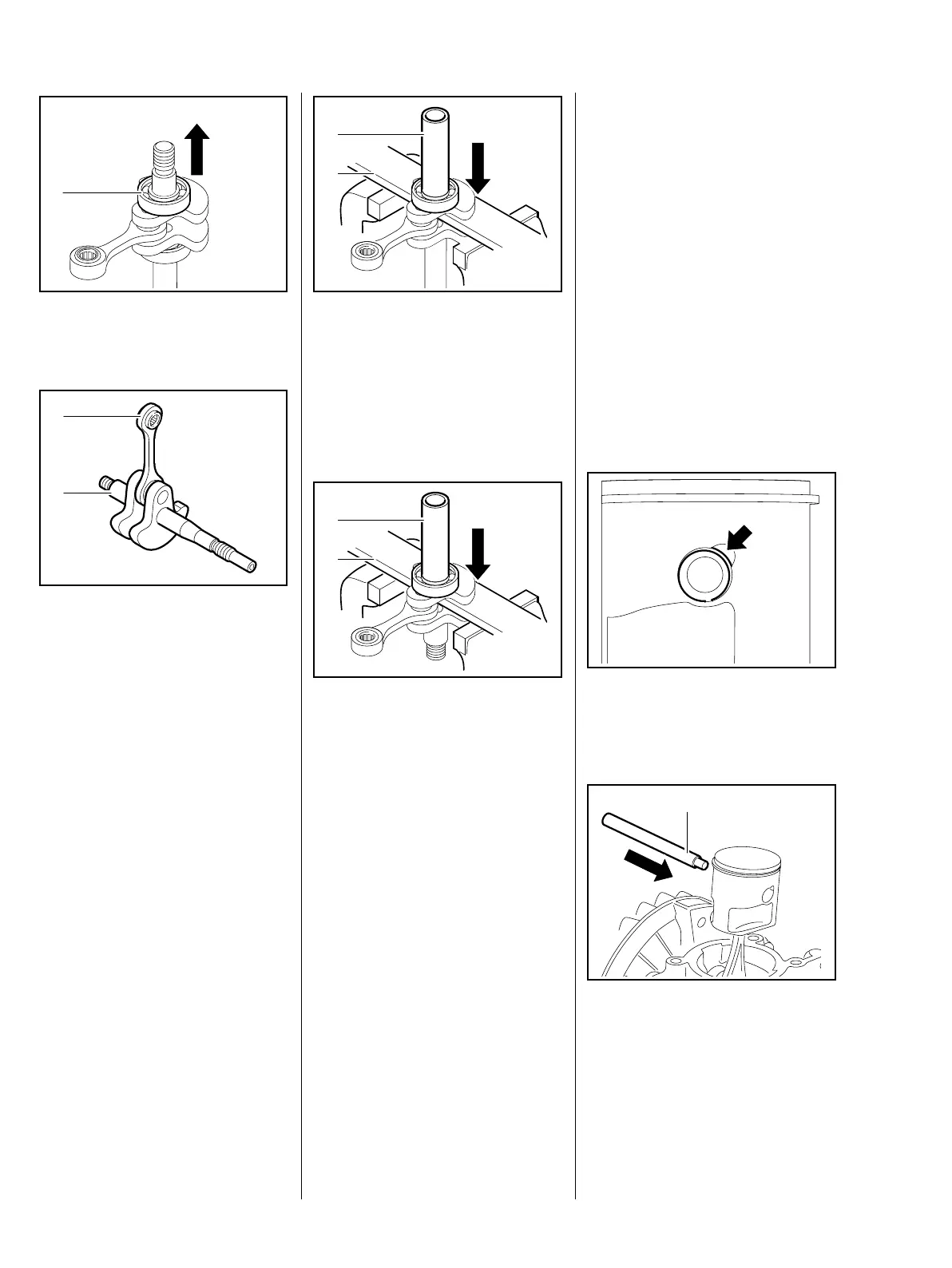

The piston has only one snap ring. It

is fitted at the carrier side (short

crankshaft stub).

: Use a suitable tool to grip the

hookless snap ring at the recess

(arrow) and ease it out.

: Apply assembly drift (1)

1130 893 4700, small diameter

first, to the ignition side of the

piston.

938RA062 TG

1

938RA063 TG

Loading...

Loading...