76 MS 171, MS 181, MS 211

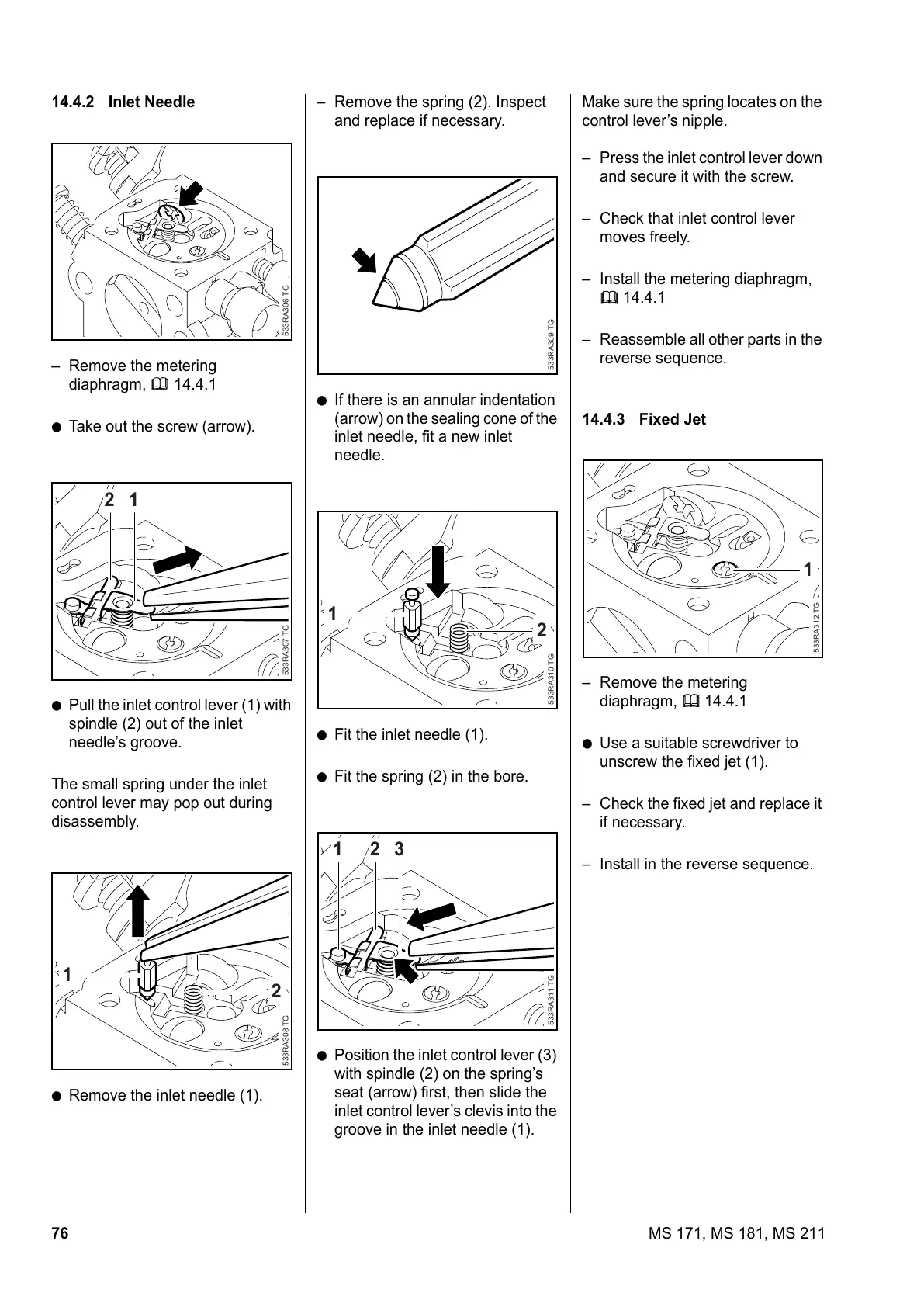

14.4.2 Inlet Needle

– Remove the metering

diaphragm, b 14.4.1

: Take out the screw (arrow).

: Pull the inlet control lever (1) with

spindle (2) out of the inlet

needle’s groove.

The small spring under the inlet

control lever may pop out during

disassembly.

: Remove the inlet needle (1).

533RA306 TG

1

533RA307 TG

2

533RA308 TG

1

2

– Remove the spring (2). Inspect

and replace if necessary.

: If there is an annular indentation

(arrow) on the sealing cone of the

inlet needle, fit a new inlet

needle.

: Fit the inlet needle (1).

: Fit the spring (2) in the bore.

: Position the inlet control lever (3)

with spindle (2) on the spring’s

seat (arrow) first, then slide the

inlet control lever’s clevis into the

groove in the inlet needle (1).

533RA309 TG533RA310 TG

1

2

3

533RA311 TG

21

Make sure the spring locates on the

control lever’s nipple.

– Press the inlet control lever down

and secure it with the screw.

– Check that inlet control lever

moves freely.

– Install the metering diaphragm,

b 14.4.1

– Reassemble all other parts in the

reverse sequence.

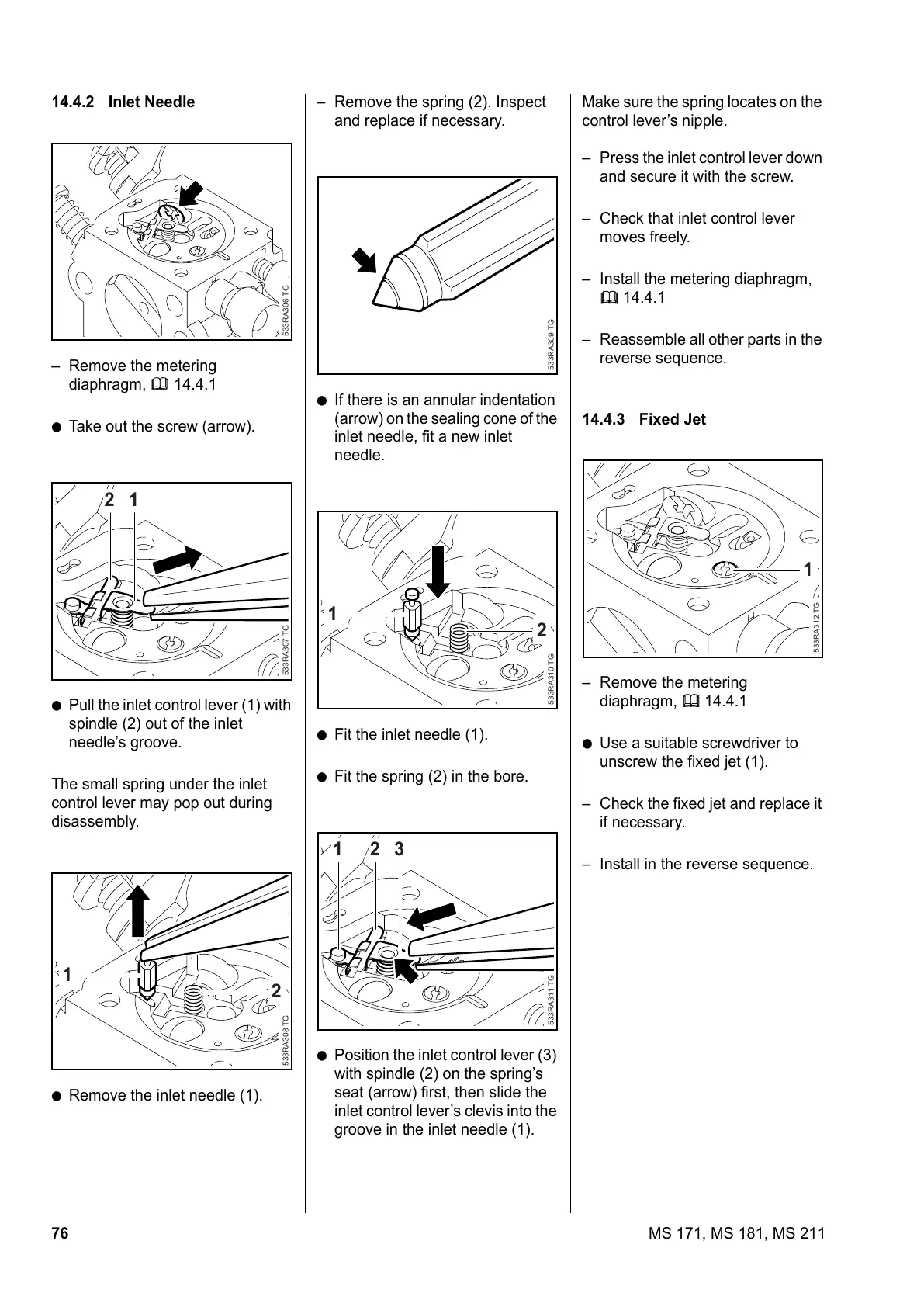

14.4.3 Fixed Jet

– Remove the metering

diaphragm, b 14.4.1

: Use a suitable screwdriver to

unscrew the fixed jet (1).

– Check the fixed jet and replace it

if necessary.

– Install in the reverse sequence.

533RA312 TG

1

Loading...

Loading...