► Lower the depth gauges (2) and tie straps (3)

with a STIHL USG universal sharpener using

the following settings:

–

Scale A: + 40°

–

Scale B: 0°

–

Scale C: 0°

17 Repairing

17.1 Repairing the Chain Saw,

Guide Bar and Saw Chain

The chain saw, guide bar and saw chain cannot

be repaired by the user.

► If the saw, guide bar or saw chain is damaged:

Do not use your saw, guide bar or saw chain,

and contact your STIHL servicing dealer.

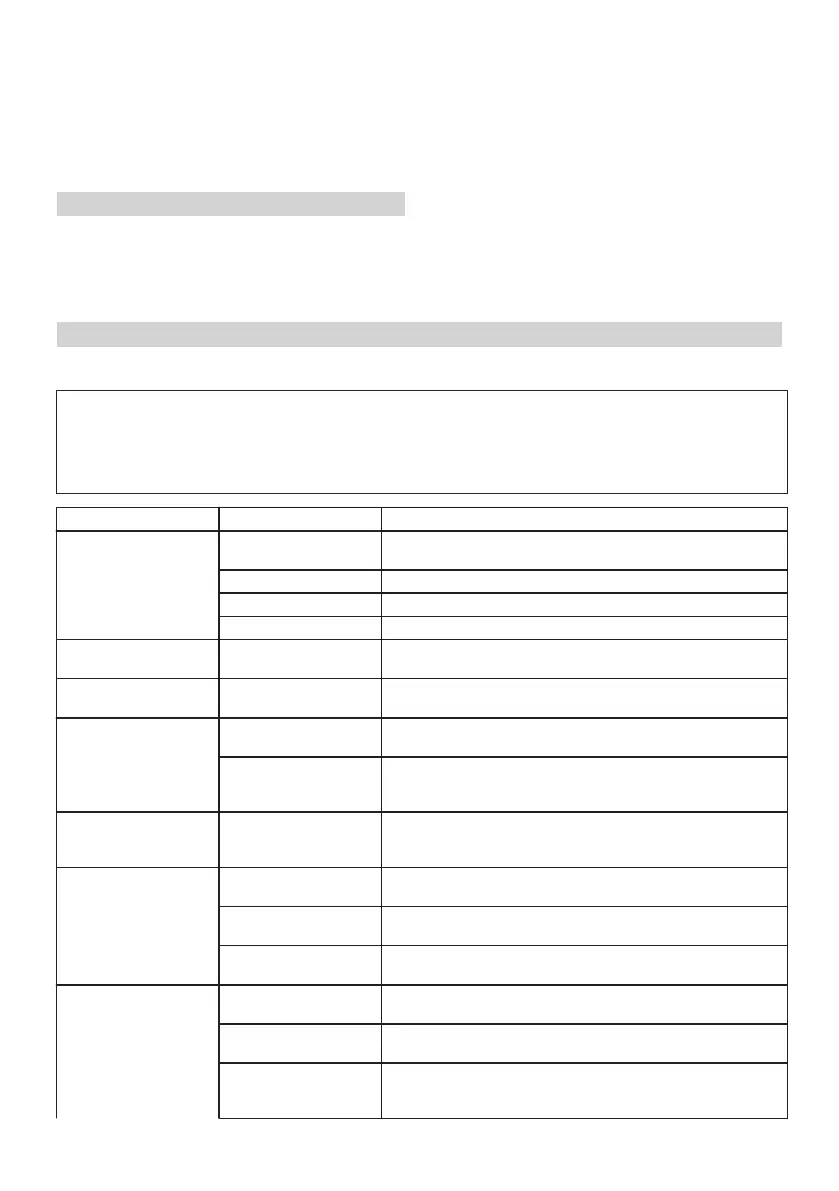

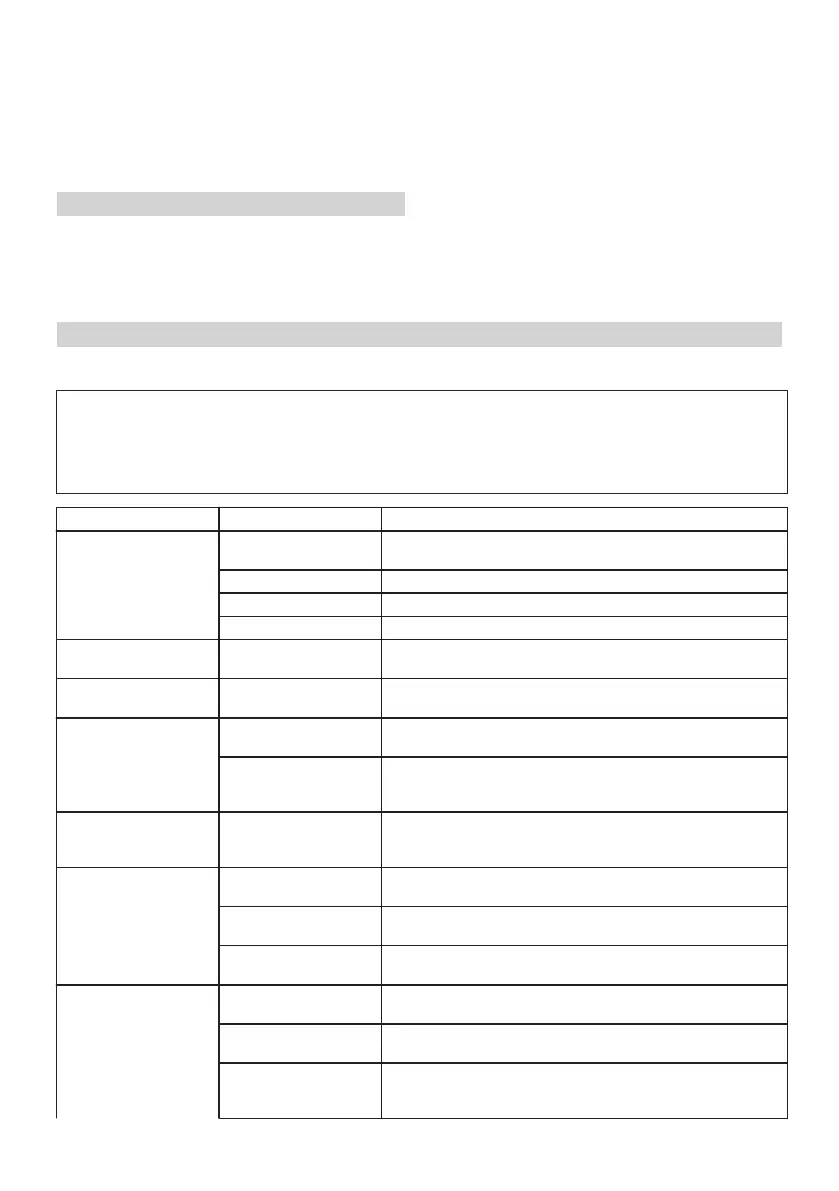

18 Troubleshooting

18.1 Troubleshooting Chainsaw

Most malfunctions have the same causes.

► Perform the following operations:

► Clean the air filter.

► Clean or replace the spark plug.

► Adjust saw for winter or summer operation.

► If the malfunction still exists: Take the action described in the following table.

Condition Cause Remedy

Engine does not

start.

Insufficient fuel in the

tank.

► Mix fuel and refuel the chainsaw.

Engine is flooded. ► Clear the combustion chamber.

Carburetor is too hot. ► Allow chainsaw to cool down.

Carburetor is iced up. ► Allow saw to warm up to +10°C.

Engine idles errati‐

cally.

Carburetor is iced up. ► Allow saw to warm up to +10°C.

Engine stops while

idling

Carburetor is iced up. ► Allow saw to warm up to +10°C.

Poor acceleration The chain is over-ten‐

sioned.

► Tension chain properly.

Chain lubrication sys‐

tem is supplying

insufficient chain oil.

► Increase oil feed rate.

Engine does not

reach maximum

RPM.

Saw is not correctly

tuned to ambient con‐

ditions.

► Calibrate the saw.

Saw chain does not

rotate when throttle is

opened.

The chain brake is

engaged.

► Disengage the chain brake.

The chain is over-ten‐

sioned.

► Tension chain properly.

Bar nose sprocket is

blocked.

► Clean the bar nose sprocket with STIHL resin solvent.

Smoke or burning

smell while cutting.

Chain is not properly

sharpened.

► Sharpen the chain properly.

Insufficient chain oil

in the tank.

► Fill up with chain oil.

Chain lubrication sys‐

tem is supplying

insufficient chain oil.

► Increase oil feed rate.

17 Repairing English

0458-787-0121-B. VA0.M20. 23

Loading...

Loading...