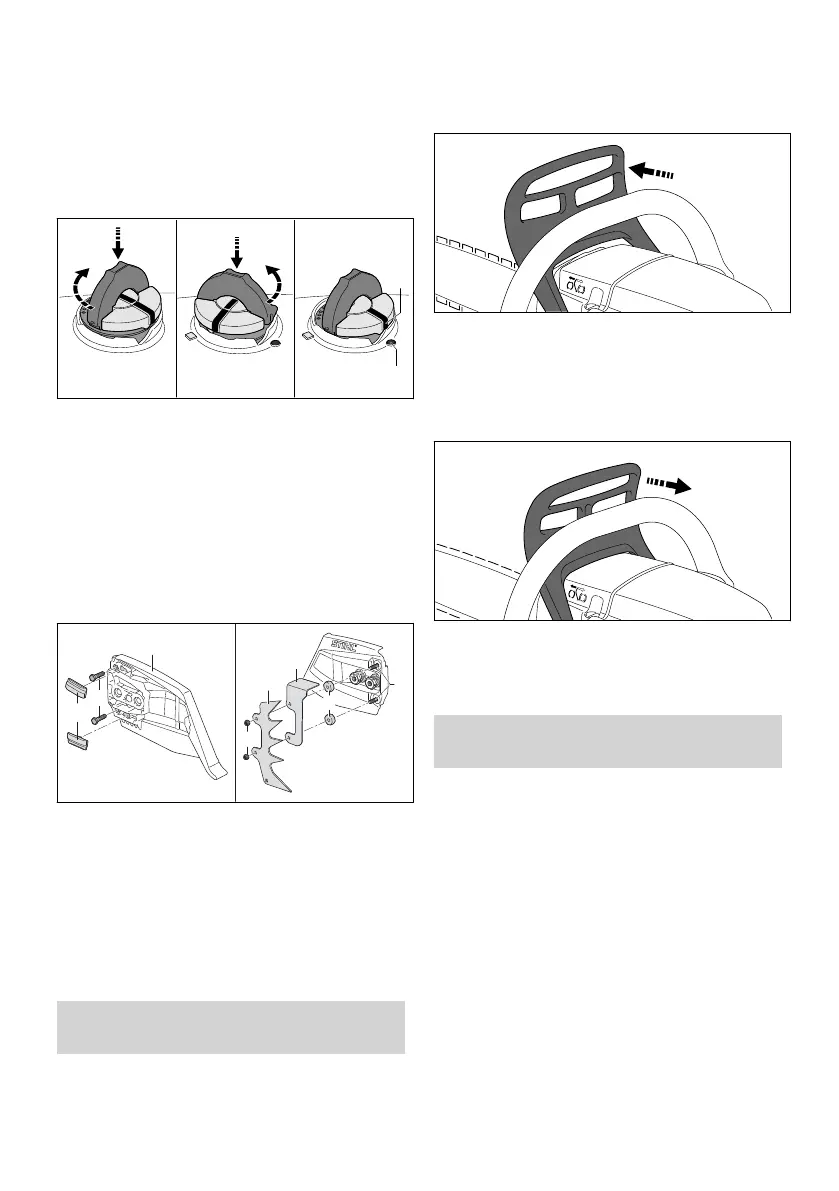

► If the oil tank cap cannot be pulled upwards

and off: Fold down the grip on the oil tank cap.

The oil tank is closed.

If the oil tank cap can be pulled upwards and off,

perform the following steps:

► Place the oil tank cap in the filler opening – in

any position.

► Press the cap down and rotate it clockwise as

far as stop.

► Press the cap down and rotate it counterclock‐

wise until mark (1) points to mark (2).

► Now try again to close the oil tank.

► If the oil tank still cannot be closed properly:

Do not use the chainsaw and contact a STIHL

dealer for assistance.

The chainsaw is not in a safe condition.

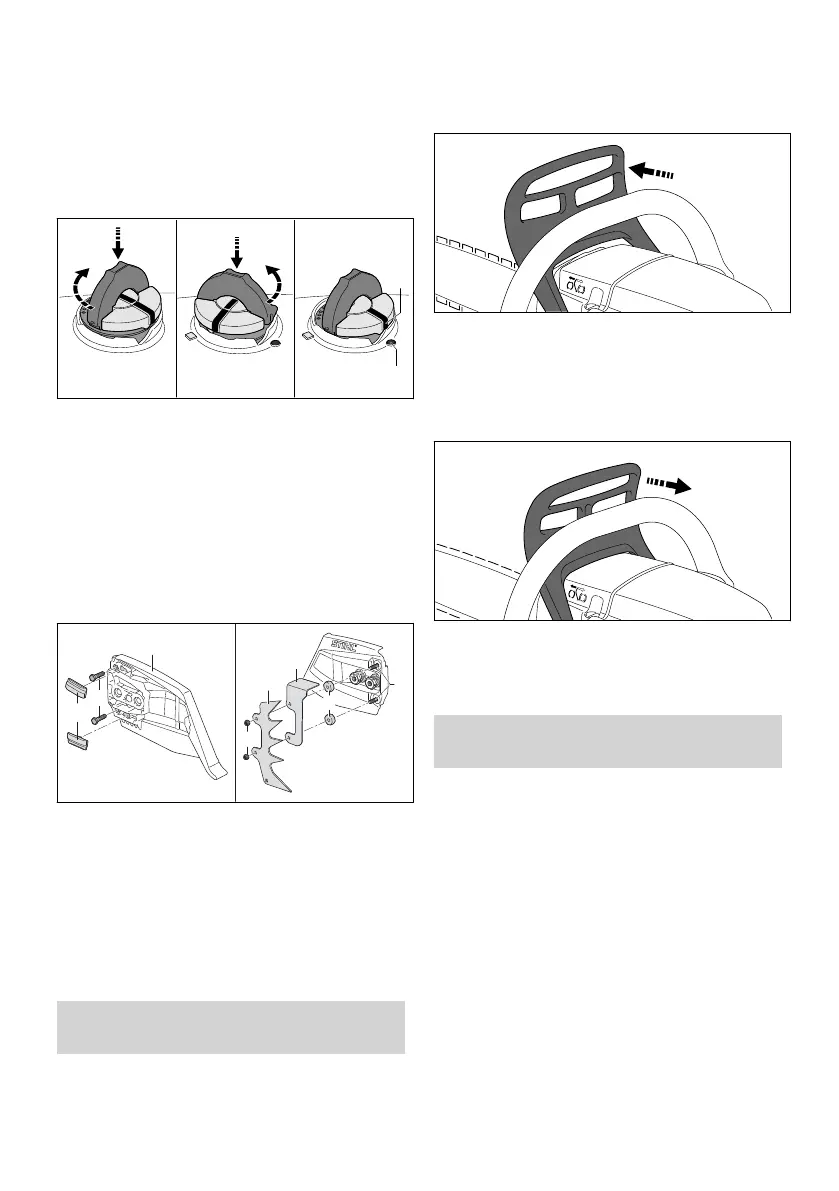

6.5 Mounting the Spiked Bumper

► Insert the screws (2) through the holes in the

chain sprocket cover (3) as far as stop.

► Push the bumper strips (1) into the recess in

the chain sprocket cover (3).

► Fit the washers (7).

► Fit the cover (6) in position.

► Fit the spiked bumper (5).

► Fit and tighten down the nuts (4) firmly.

The spiked bumper (5) must not be removed.

7 Engaging and Disengaging

the Chain Brake

7.1 Engaging the Chain Brake

The saw is equipped with a chain brake.

The chain brake is activated by the inertia of the

front hand guard if the kickback force is high

enough or can be engaged by the operator.

► Push the hand guard away from the front han‐

dle with your left hand.

The hand guard engages with an audible click.

The chain brake is engaged.

7.2 Disengaging the Chain Brake

► Pull the hand guard toward the front handle

with your left hand.

The hand guard engages with an audible click.

The chain brake is disengaged.

8 Mixing Fuel and Refueling

the Chainsaw

8.1 Mixing Fuel

This chainsaw requires a fuel mixture of gasoline

and two-stroke engine oil in a ratio of 50:1.

STIHL recommends you use STIHL MotoMix.

If you mix the fuel yourself, use only STIHL two-

stroke engine oil or another high-performance

engine oil in accordance with JASO FB, JASO

FC, JASO FD, ISO-L-EGB, ISO-L-EGC or ISO-L-

EGD.

STIHL specifies STIHL HP Ultra two-stroke

engine oil or an equivalent high-performance

engine oil in order to maintain emission limits

throughout the machine’s service life.

► Make sure that the octane number of the gas‐

oline is at least 90 RON and the ethanol con‐

tent is not more than 10%.

7 Engaging and Disengaging the Chain Brake English

0458-787-0121-B. VA0.M20. 13

Loading...

Loading...