•

Slide assembly arbor with

high-pressure cup into the larger

opening in the assembly sleeve

(interior of sleeve is tapered).

- Press sleeve against a soft, level

and clean surface and adjust

arbor until cup is flush with end

of sleeve.

- Position complete assembly

device on valve block. The

collar fits into the seat of the

high-pressure cup.

•

Drive high-pressure cup into seat

in valve block with the assembly

arbor.

- Fill grooves of oil seals with spe-

cial grease 0781 145 3516.

•

Slide oil seal onto assembly

arbor with the groove facing

upwards. The sealing lip of the

oil seal fits into the recess on the

assembly arbor.

- Press oil seal into pump

housing with assembly tool

4726 890 2200 in the same

way as the high-pressure cups.

Do not damage the sealing lip.

- Insert support rings in pump

housing and press in with

assembly arbor.

Reassemble remaining parts in

reverse order.

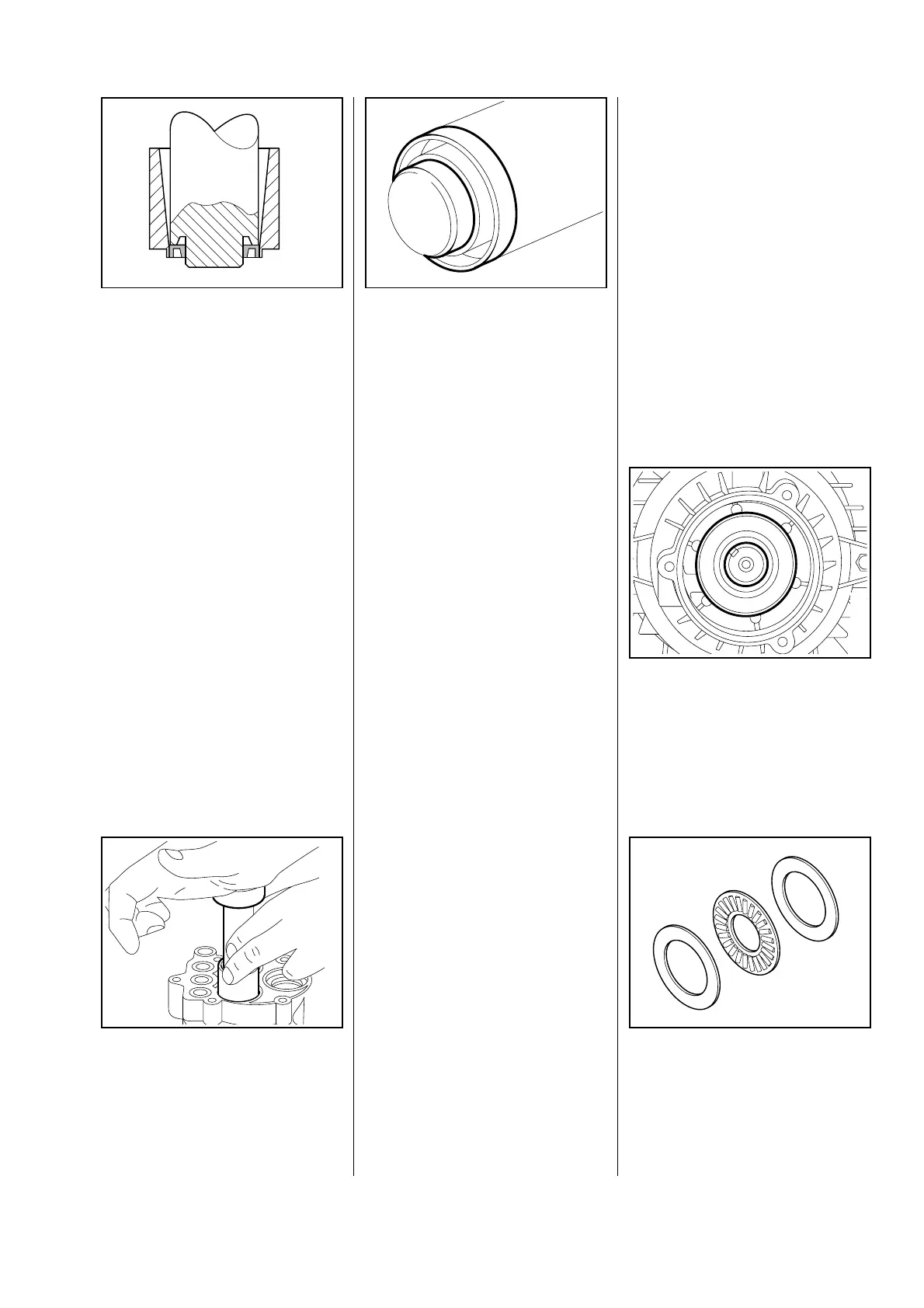

- Installation position of guide

bushing: see diagram.

- Remove shroud (see 5.1) and

motor / pump unit (see 5.2).

- Remove safety control block

(see 6.1), valve block (see 7.3)

and pump housing (see 7.4).

The outer thrust bearing is

removed and installed in the same

way as on the high-pressure

cleaners of series RE 102 K,

104 K and 106 K.

RE 160 K only

•

Pull swashplate (1) and inner

thrust bearing off the drive shaft.

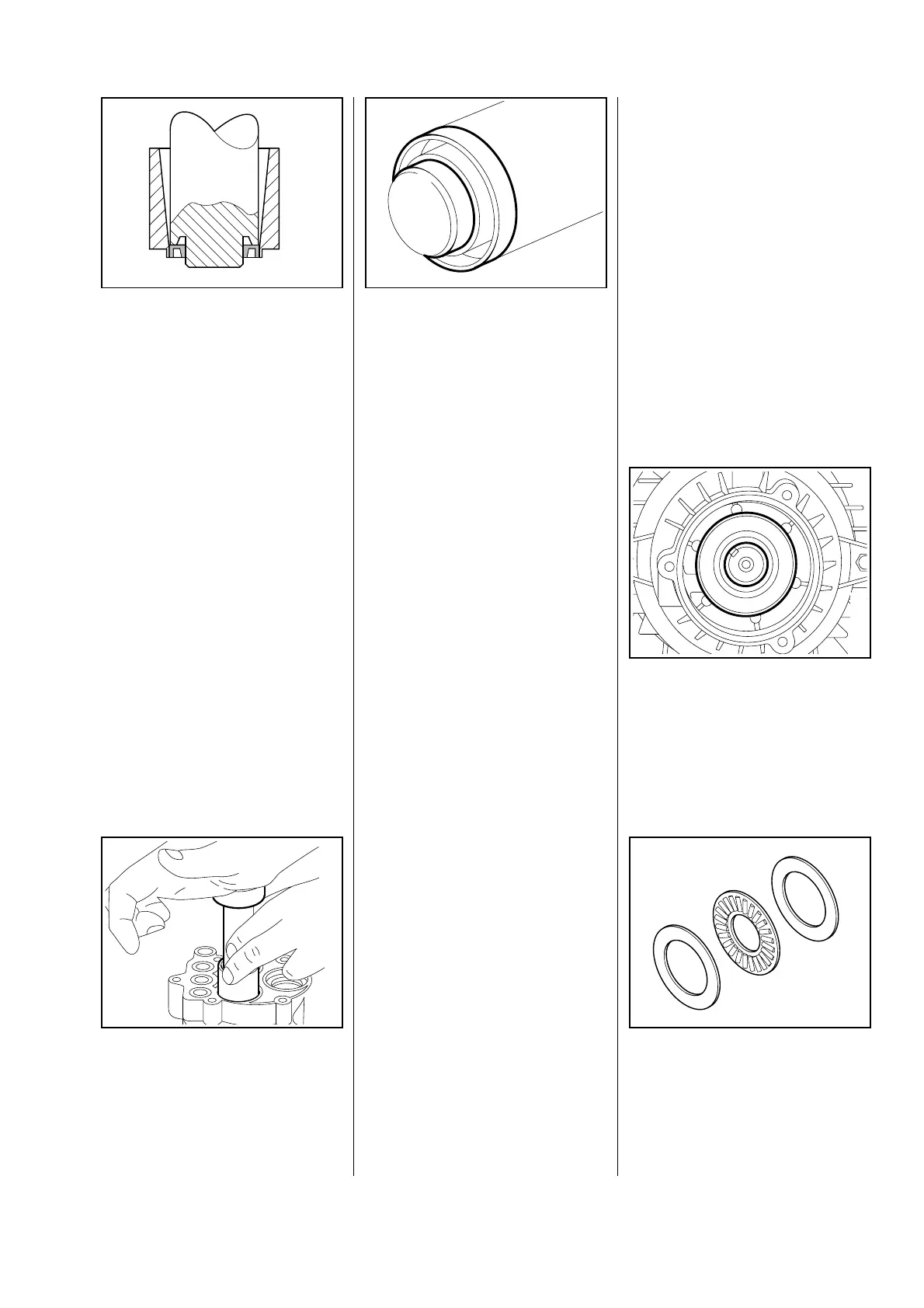

Examine the various parts of the

outer (see RE 102/104/106 K) and

inner thrust bearing and replace if

necessary: upper washer (1), cage

with bearing rollers (2) and bottom

washer (3).

7.7 Replacing thrust bearings

21RA082 BL

621RA046 BL

1

621RA047 BL

1

2

3

21RA081 BL

RE 140 K, 160 K 17

Loading...

Loading...