22

Auto Backush Connued...

If you have used soap or another cleanser during the backush, run the backush process a second me with

no soap or chemicals to rinse the internal tubing and brew valve. Failure to rinse aer a soap backush can

leave soap residue in the brew valve aecng taste and/or machine behavior.

Any number of brew groups can use the auto backush feature at the same me. The auto backush can be

interrupted mid-cycle by moving the brew head to either side, pressing the purge buon, or by turning the

seng on the controller back to “o”.

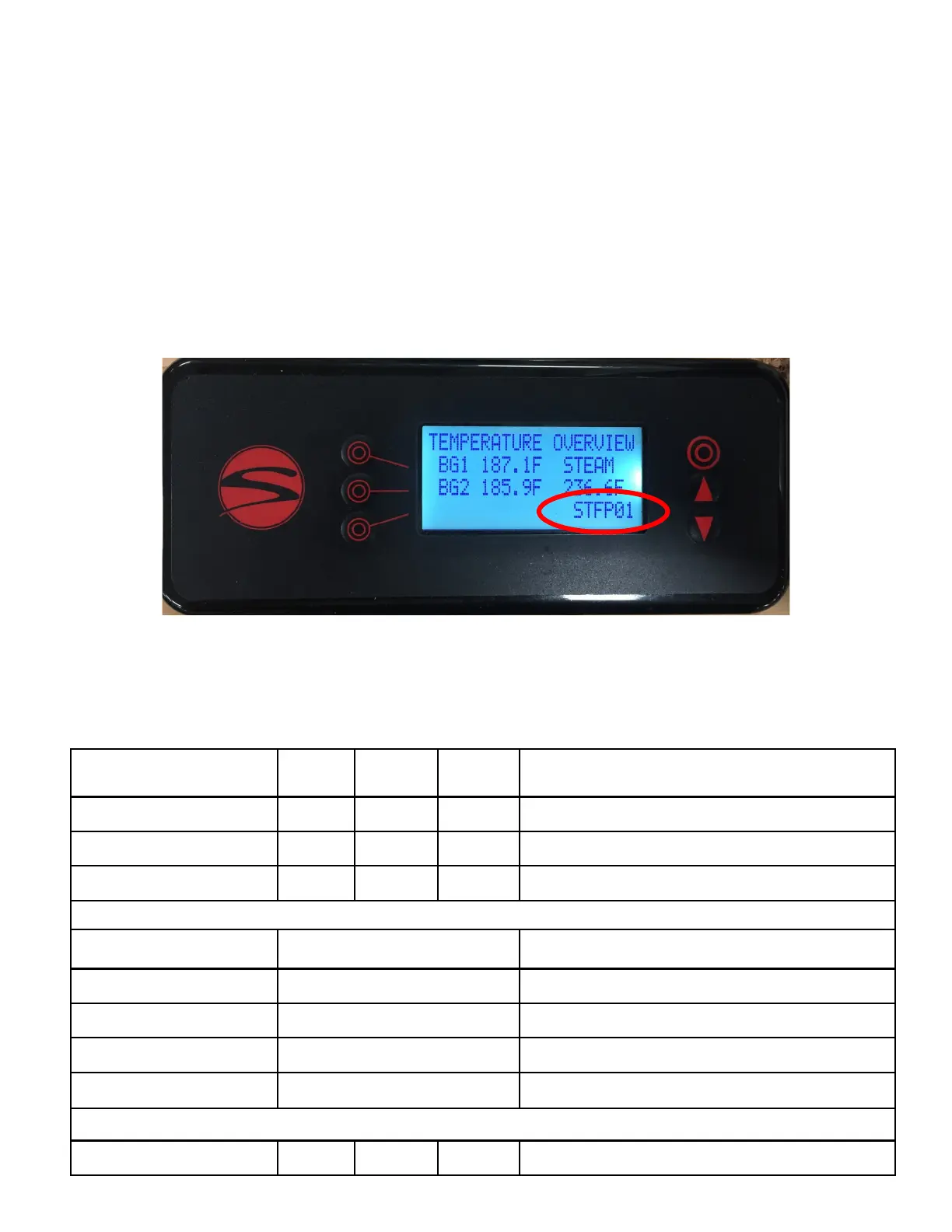

To cycle back to the temperature overview screen, press the down buon.

In an eort to prevent damage to machines and to help operators troubleshoot issues, Synesso has engi-

neered several safeguards into the programming. By understanding these codes, operators can remedy is-

sues more quickly. The most recent error can be found on the temperature overview screen at the lower

right corner. An error found there is not necessarily happening currently.

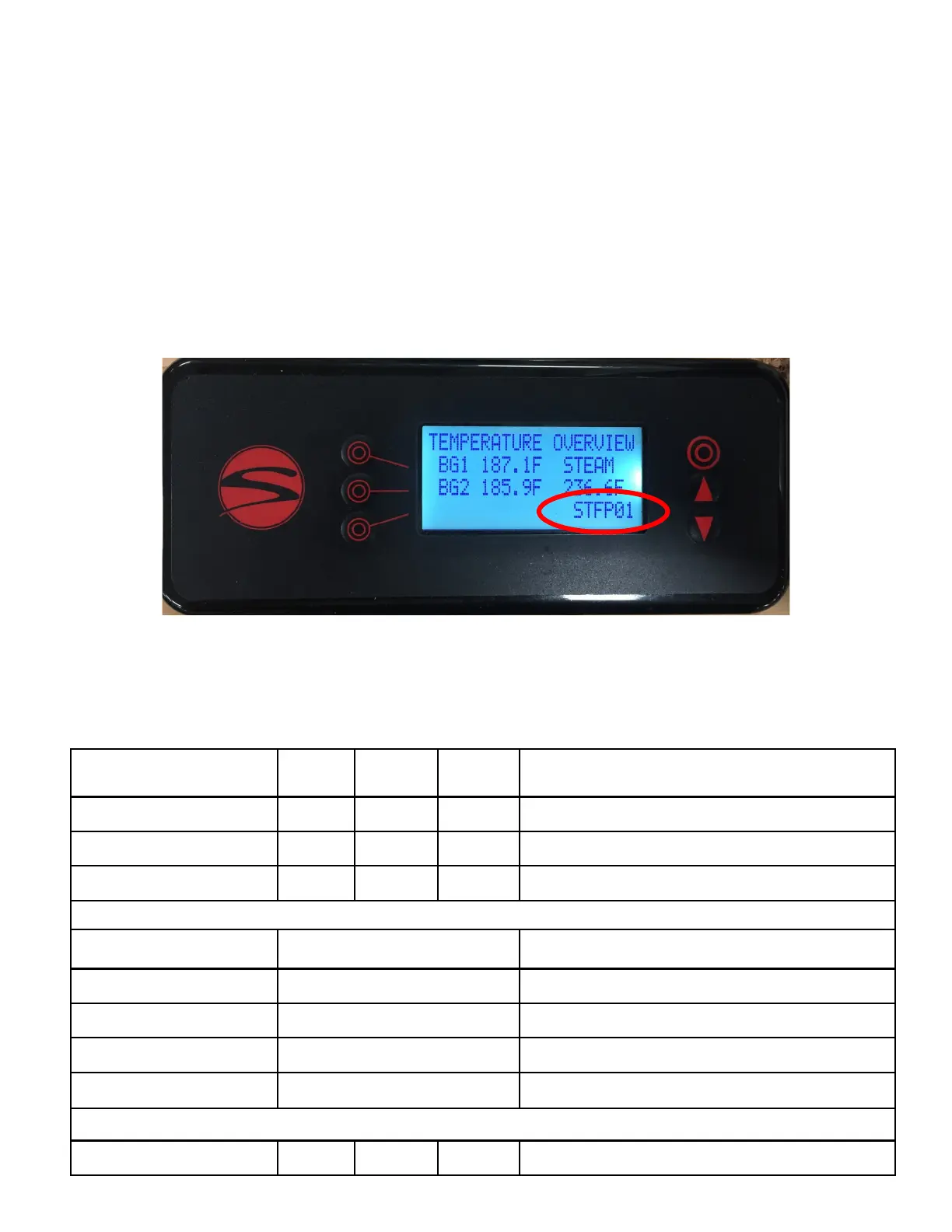

BR - Brew System Codes

GROUP

1

GROUP

2

GROUP

3 CODE DESCRIPTION

BV - Brew valve BRBV01 BRBV02 BRBV02 Brew Valve has been on for 5 consecuve minutes

OT - Over Temp BROT01 BROT02 BROT02 Over Temperature (220°F)

UT - Under Temp BRUT01 BRUT02 BRUT02 Group reads < 180°F for 1 minute while reheang

ST - Steam System Codes

LOW H2O LOW H2O

Low level probe not in contact with water (audible

alarm)

LW - Low Water Probe STLW00 Indicates past LOW H2O warning

FP - Fill Probe STFP00 Fill Probe is not in contact with water for 1 minute

FV - Fill Valve STFV00 Fill Valve has been on for 5 consecuve minutes.

OT - Over Temp Over Temperature (270°F) STOT00

VM - Volumetric System Codes

UF - Unexpected Flow VMUF01 VMUF02 VMUF02 Unexpected ow detected while group is o

Menu Level 1: Brew System Error Codes

PROGRAMMING

Loading...

Loading...