2

Congratulations on your purchase of a Thunder Tiger model engine. All Thunder Tiger engines

have been designed to combine high performancewith easy handling and maintenance using

CAD computer technology. Major components of the engines are machined from the highest

quality materials using state-of-the-art CNC manufacturing techniques, resulting in consistent

high quality and reliability.

The PRO series engines are equipped with dual ball bearings, Schnuerle porting, a special ABN

type piston and cylinder sleeve, and automatic mixture control carburetors with safe angular

needle valve. The engines have been designed for both beginners and experienced flyers.

This engine will provide you with years of safe use, provided that you carefully follow these safety

instructions:

• This model engine IS NOT A TOY, but a powerful miniature engine that is capable of inflicting

damage to both people and property if misused.

• Always mount the engine securely in a test stand or high-quality engine mount. Never, ever

attempt to clamp your engine in a vise!

• Keep all spectators at least 20 feet away when operating your engine.

• Make sure that you use the correct propeller for your engine. See chart.

• Make sure that the propeller nut is securely fastened prior to each flight.

• Keep your body away from the path of the propeller when running your engine.

• Keep your hands away from the propeller, by using a “chicken stick” or electric starter to

start your engine.

3

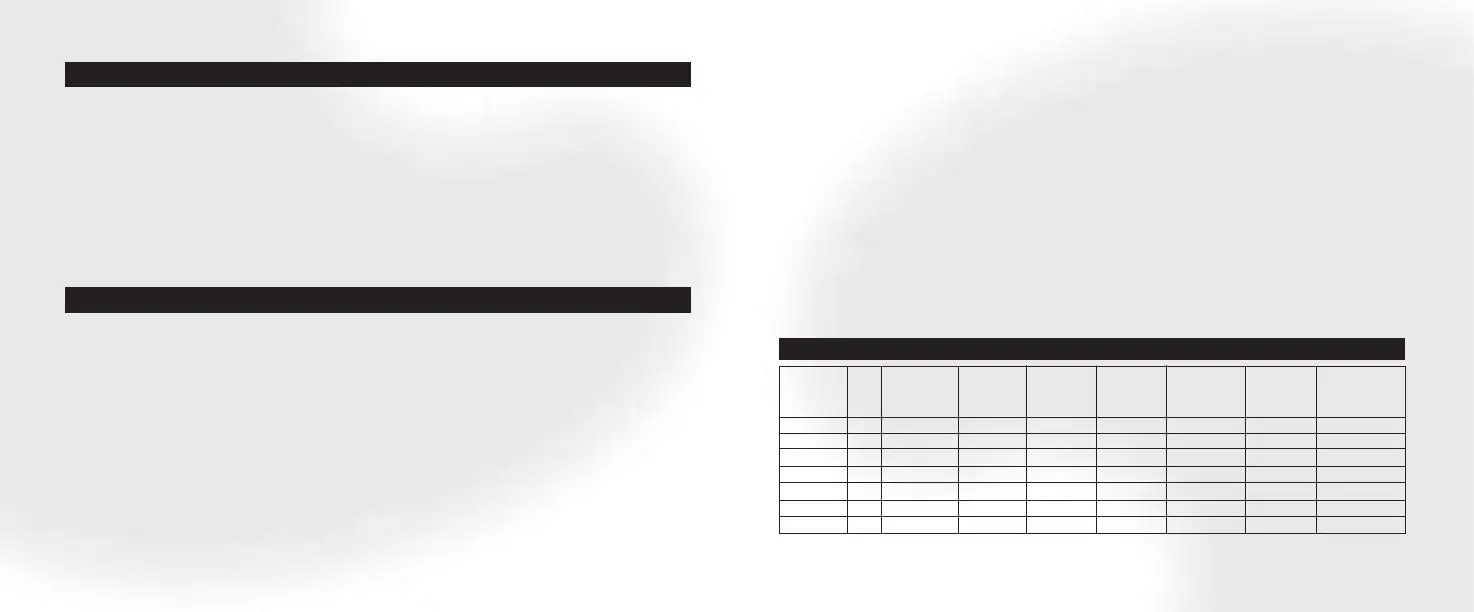

Engine Crankshaft

Thread

Practical RPM Weight

(g/oz.)

0.365PRO-36

PRO-40

PRO-46

PRO-61

PRO-91

PRO-120

313.6 / 11.06

454.5 / 16.03

448.5 / 15.82

758.4 / 26.75

(*1)562.0 / 19.83

975.0 / 34.49

(*1)780 / 27.51

1.1 / 16,000

1.30 / 16,000

1.60 / 16,000

1.85 / 16,000

2.75 / 15,000

3.2 / 14,000

3.5 / 14,000

PRO-120RP

Item

No.

9130

9140

9141

9160

9190

9195

9196

Displacement

(cc/cu.in)

5.98 /

6.52 / 0.398

7.47 / 0.456

9.98 / 0.609

14.96 / 0.913

20.76 / 1.267

20.76 / 1.267

20.8 / 0.819

20.9 / 0.823

21.8 / 0.858

23.5 / 0.925

28.0 / 1.102

31.0 / 1.220

31.0 / 1.220

Specifications

• Make all carburetor adjustments from behind the propeller.

• Never use your hands or any other part of your body to stop the propeller. Do not throw

any object into the propeller to stop the engine. Stop the engine by removing the fuel line,

pinching the fuel line closed or closing the throttle barrel completely.

• Never use a propeller that is cracked, nicked or damaged in any way.

• It is recommended that you wear safety glasses when operating any model engine.

• Do not run your engine around dirt, sand or loose gravel. Such material can be thrown into

your eyes by the propeller, as well as damaging the engine if drawn into the carburetor.

• Take care to keep all loose clothing rags, tools etc. away from the propeller.

• Keep all fuel lines, glow clips, starter cords, etc. away from the propeller.

• Take care when handling your engine after it’s been running as model engines get very hot

during operation!

• Always operate your engine with proper ventilation. Model engines produce harmful fumes

when run in a closed room or confined area.

Important

An Introduction to PRO Engines

Bore

(mm/in)

17.6 / 0.693

19.0 / 0.748

20.0 / 0.787

23.0 / 0.906

24.3 / 0.957

27.5 / 1.083

27.5 / 1.083

Stroke

(mm/in)

2,000~17,000

2,000~17,000

2,000~17,000

2,000~17,000

2,000~16,000

1,800~15,000

1,800~15,000

UNF 1/4-28

UNF 1/4-28

UNF 1/4-28

UNF 5/16-24

UNF 5/16-24

UNF 5/16-24

UNF 5/16-24

OUTPUT

(BHP/RPM)

(w/muffler)

(*1)wo / muffler

Loading...

Loading...