7

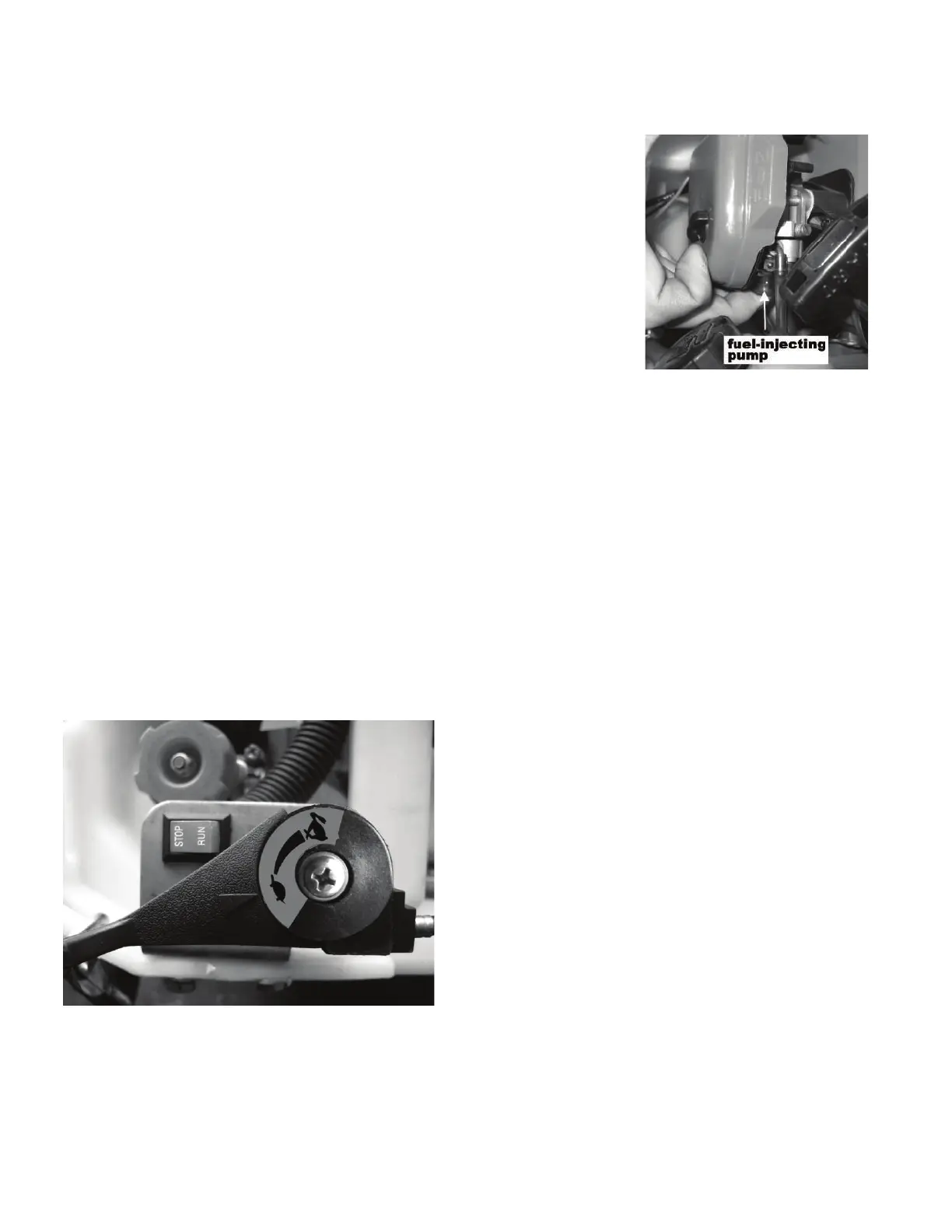

5.2.3 Move the fuel handle in the starting position (about one third of the whole scale).

See Figure 3.

5.2.4 Pull the starter lightly 3-5 times to push fuel into the cylinder. Then pull faster to start the

engine.

Figure 3

5.3 Spraying

5.3.1 When adding chemical liquid, it should be poured slowly into the chemical tank. The liquid

must be poured through the filter in order to avoid undesired matter from entering into the liquid

tank, which could cause harm to the chemical tank or engine. After adding liquid, screw down the

chemical tank lid in order to avoid leakage.

5.3.2 Regulate the choke (see Figure 4) to the closed position to start and then move to the full

open position when the engine is hot.

5.Operating Instructions

5.1 Preparation before start

5.1.1 Connecting spraying parts. Before starting, verify all the connections are working.

1

.Long Spraying Nozzle

2.Washer

3.Straight Spraying Tube

4.Valve

5.Handle

6.Plastic Tube

Never fill the fuel tank to the very top.

Never add fuel to the tank in a closed non-ventilated area.

Do not add fuel to this unit close to a open fire or sparks.

Be sure to wipe off spilled fuel before attempting to start the engine.

Do not attempt to refuel a hot engine.

5

.2 Start

5.2.1 Adding fuel. This gasoline engine is a single-cylinder, two stroke. The engine uses a fuel

mixture of No. 90 gasoline and two-strole oil. The gasoline oil mixture ratio is of 30:1 (gasoline : oil)

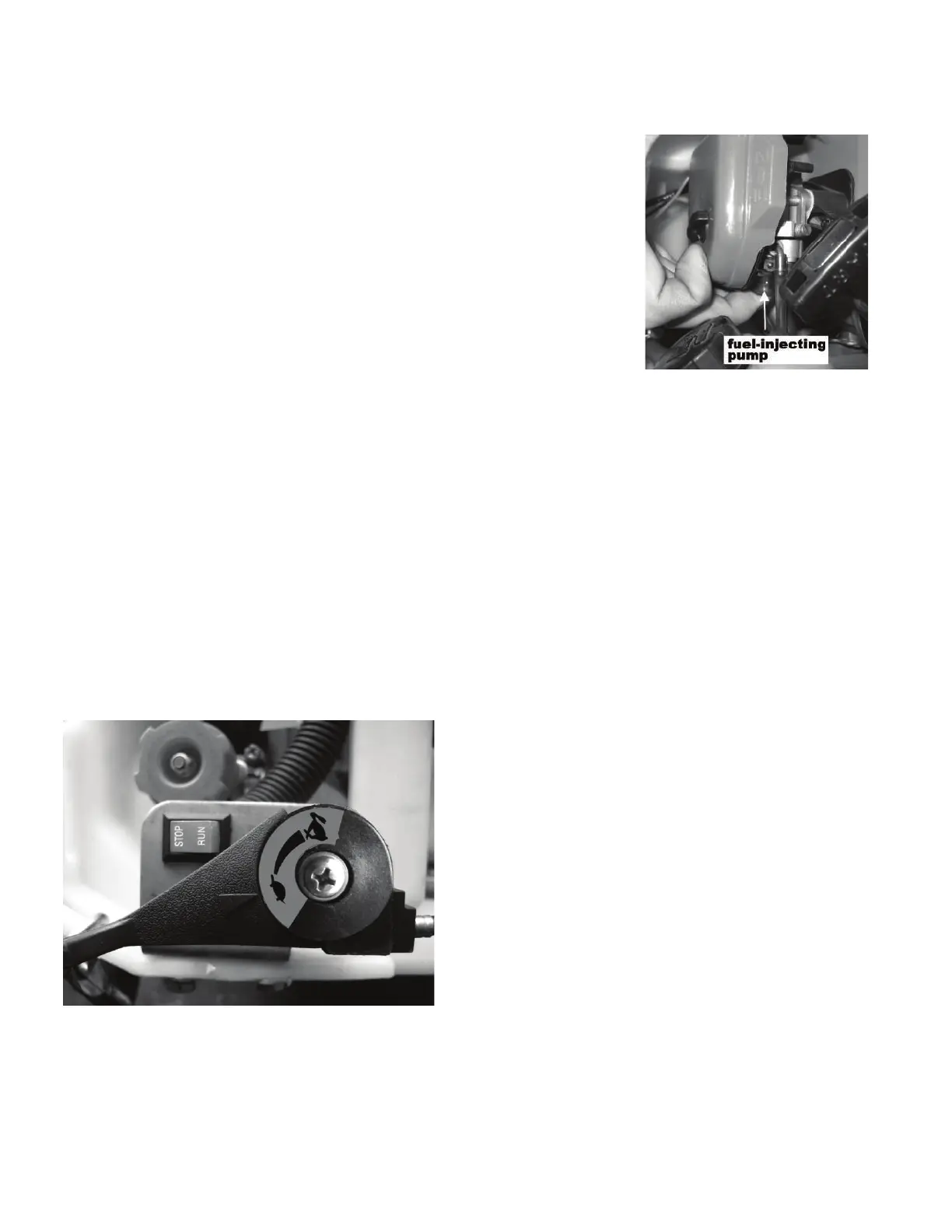

5.2.2 Push the fuel-injecting pump continuously until the pump is visibly is full.

5.1.2 Check that all the connections are correct and stable.

5.1.3 For long term storage, oil sealed must be removed first. To remove: Take off the spark plug,

use the lift thumb to stop the spark plug hole and pull the starter to remove oil.

5.1.4 Check the spark of the spark plug. Normally the sparks should be blue.

5

.1.5 Check if the air filter is clean. A dirty air filter will influence the volume of incoming air that

may cause bad engine performance.

Figure 2

Note: After starting the engine, the recoil starter

should be retracted slowly. If the rope on the recoil

retracts fast, it may cause damage to the engine.

5.2.5 Next, move the choke slowly to full open posi-

tion. Regulate the fuel handle to a proper position to

run at a low speed for 3-5 minutes.

5.2.6 New machines should not work at full open

position within the first 4 hours. The speed should

be controlled at 4000-5000 rpm.

Loading...

Loading...