Figure55

1.Spacer

3.Rollerbracket

2.Sideplatemountingange

•Positionthespacerbelowthesideplatemounting

angewhenheightofcutsettingsrangefrom

1/8"to1"(Figure56).

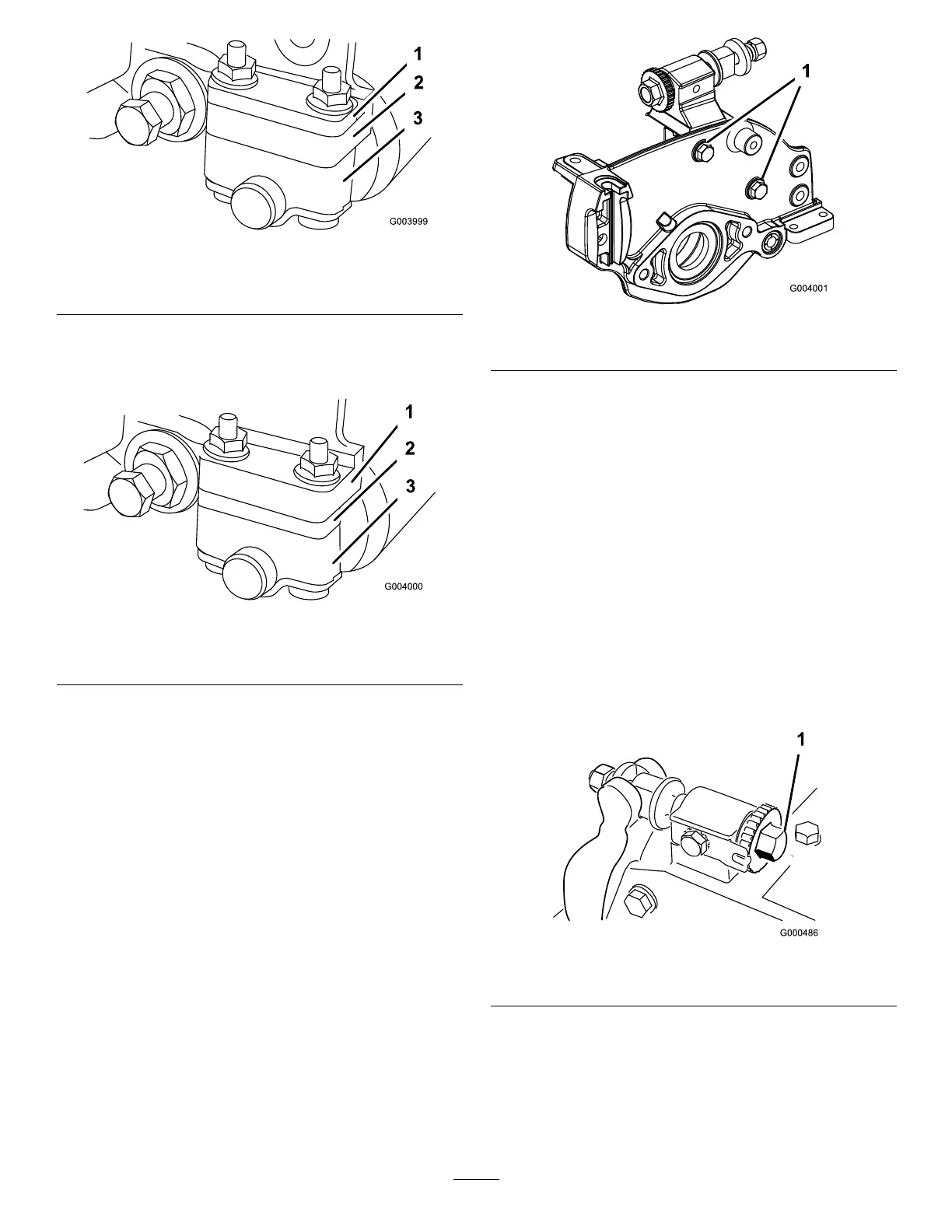

Figure56

1.Sideplatemountingange

3.Rollerbracket

2.Spacer

2.Toadjustrearrollerproceedasfollows:

•Raiserearofcuttingunitandplaceablockunder

bedknife.

•Remove(2)nutssecuringeachrollerbracketand

spacertoeachsideplatemountingange.

•Lowerrollerandscrewsfromsideplatemounting

angesandspacers.

•Placespacersontoscrewsonrollerbrackets.

•Re-securerollerbracketandspacerstounderside

ofsideplatemountingangeswithnuts

previouslyremoved.

3.Verifythatthebedknifetoreelcontactiscorrect.Tip

mowertoexposefrontandrearrollersandbedknife.

Note:Thepositionoftherearrollertothe

reeliscontrolledbythemachiningtolerancesof

theassembledcomponentsandparallelingisnot

required.Alimitedamountofadjustmentispossible

bysettingthecuttingunitonasurfaceplateand

looseningthesideplatemountingbolts(Figure57).

Adjustandre-tightenbolts.

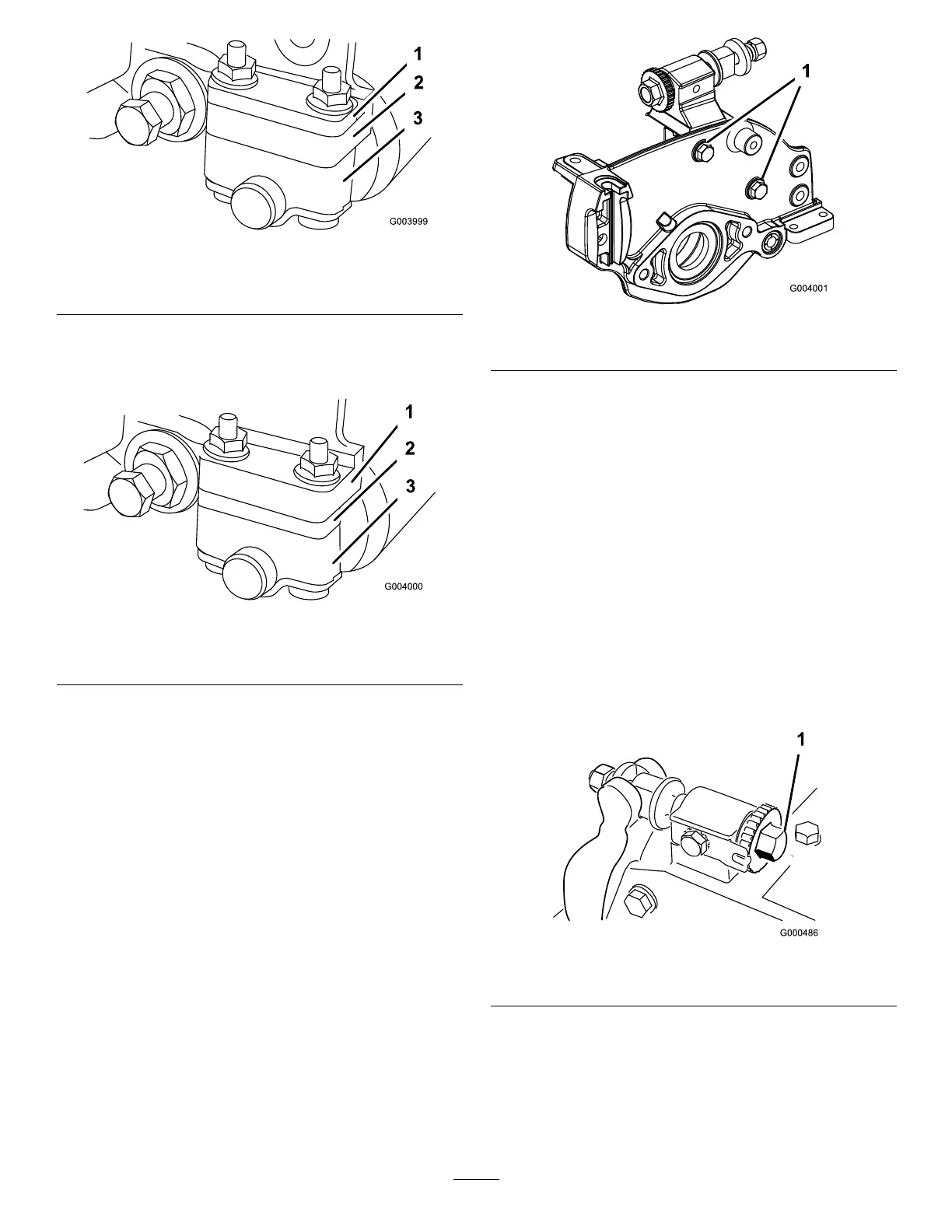

Figure57

1.Sideplatemountingbolts

Important:Wheneverthecuttingunithasto

betippedtoexposebedknife/reel,propuprear

ofcuttingunittomakesurenutsonbackend

ofbedbaradjustingscrewsarenotrestingon

worksurface.

AdjustingtheBedknifetothe

Reel

Bedknifetoreeladjustmentisaccomplishedby

looseningortighteningbedbaradjustingscrews,located

ontopofmower.

1.Positionmachineonaat,levelworksurface.

2.Makesurereelcontactisremovedbyturningbedbar

adjustingscrewscounterclockwise(Figure58).

Figure58

1.Bedbaradjustingscrew

3.Tiltmoweronbacktoexposebedknifeandreel.

4.Atoneendofreel,insertalongstripofnewspaper

betweenreelandbedknife(Figure59).Whileslowly

rotatingreelforward,turnbedbaradjustingscrew

clockwise(onsameendofreel)(Figure58),oneclick

atatime,untilpaperispinchedlightly,wheninserted

32

Loading...

Loading...