Pre-Maintenance

Procedures

Pre-MaintenanceSafety

•Disengagethedrivesandthecuttingunit,

engagetheparkingbrake,shutofftheengine,

anddisconnectthespark-plugwire.Waitforall

movementtostopbeforeadjusting,cleaning,or

repairingthemachine.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keepyourhands,feet,

clothing,andanypartsofthebodyawayfromthe

cuttingunit,attachments,andanymovingparts.

Keepbystandersaway.

•Keepallpartsingoodworkingconditionandall

hydraulicttingstight.Replaceallworn,damaged,

ormissingpartsanddecals.Keepallfasteners

tighttoensurethatthemachineisinsafeworking

condition.

•Checkthegrasscatchercomponentsfrequently

andreplacethemwhennecessary.

•Cleangrassanddebrisfromthecuttingunit,

drives,mufers,coolingscreens,andtheengine

tohelppreventres.Cleanupoilorfuelspills.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Replacefaultysilencers.

•Ifmajorrepairsareeverneededorifassistanceis

desired,contactanauthorizedTorodistributor.

•Toensureoptimumperformanceandcontinued

safetycerticationofthemachine,useonly

genuineT ororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadeby

othermanufacturerscouldbedangerous,and

suchusecouldvoidtheproductwarranty.

Lubrication

GreasingtheMachine

ServiceInterval:Every25hours

Lubricatethe12greasettingsonthemower

usingNo.2lithiumgrease.Forbestresults,usea

hand-operatedgreasegun.

Thegreasettinglocationsareasfollows:

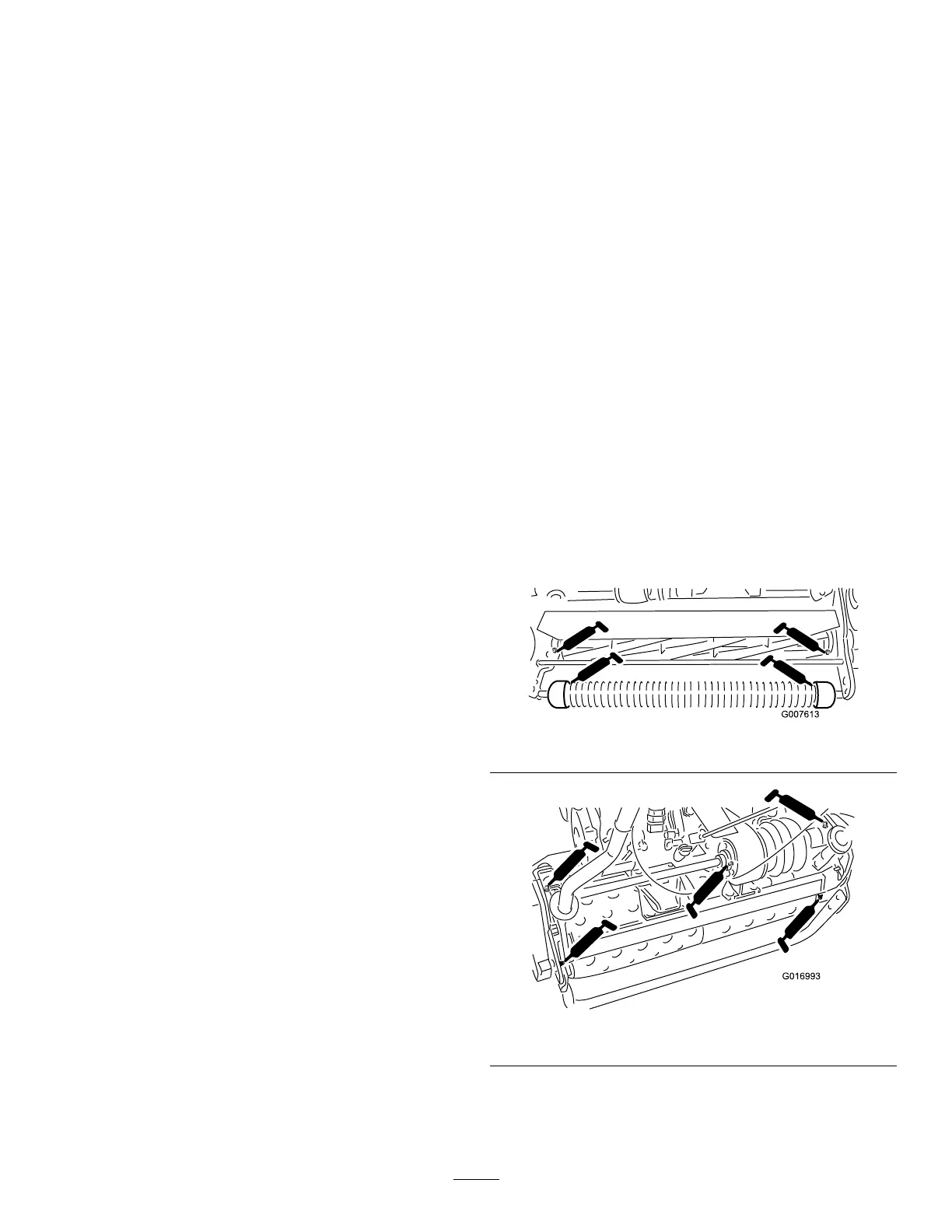

•2onthefrontroller(Figure24)

•2onthereelbearings(Figure24)

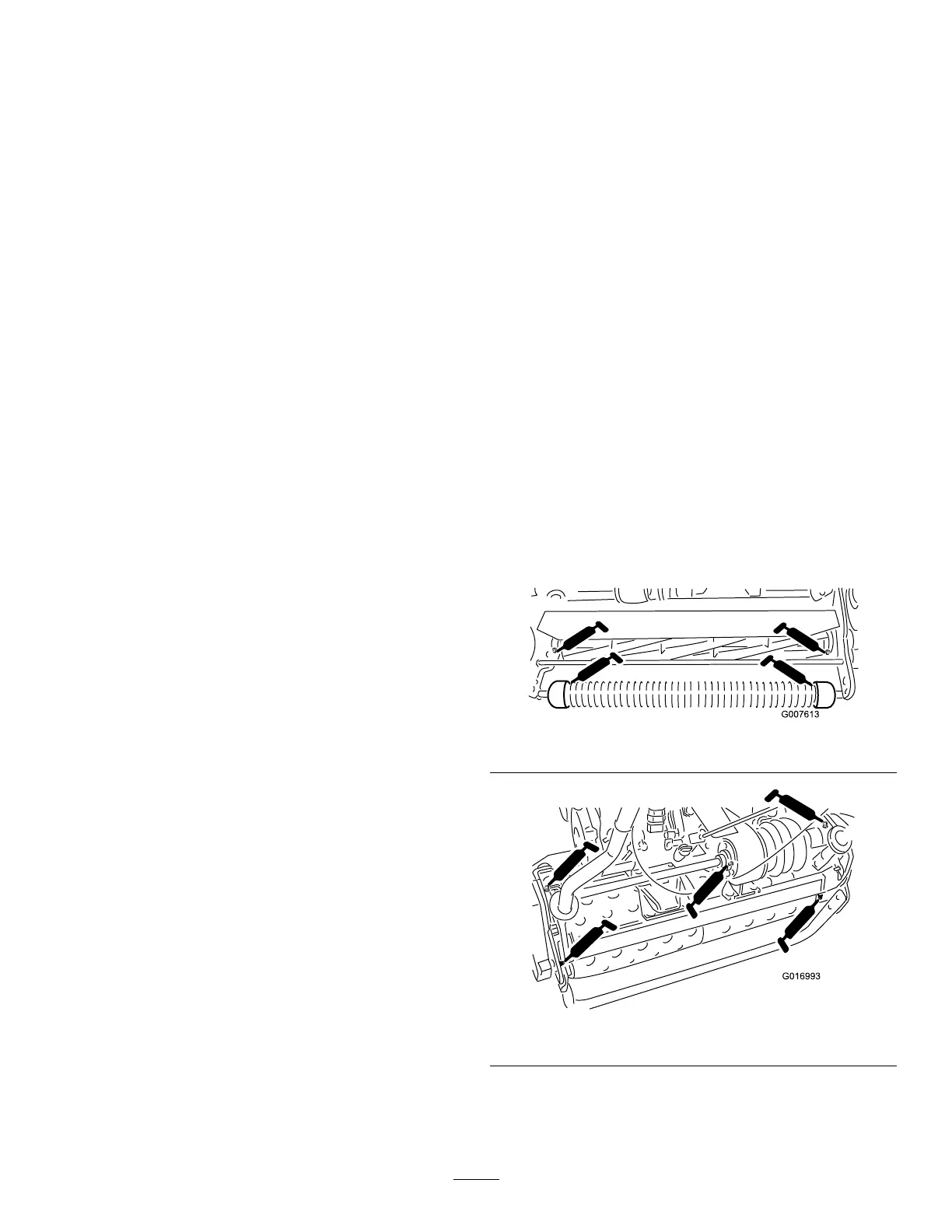

•2onthedrumaxles(Figure25)

•3onthedifferential(Figure25)

•2onthereelcountershaftbearings(Figure26)

•1onthebeltidlerpivots(Figure27).

1.Wipeeachgreasettingwithacleanrag.

2.Pumpgreaseintoeachtting.

Important:Donotapplytoomuchpressure

orthegreasesealsmaybecomepermanently

damaged.

3.Wipeoffanyexcessgrease.

g007613

Figure24

g016993

Figure25

26

Loading...

Loading...