1.Prepareasolutionofltercleanerandwater

andsoakthelterelementforabout15minutes.

Refertothedirectionsontheltercleanercarton

forcompleteinformation.

2.Aftersoakingthelterfor15minutes,rinseit

withclearwater.Rinsethelterfromtheclean

sidetothedirtyside.

Important:Topreventdamagetothelter

element,themaximumwaterpressuremust

notexceed40psi.(276kPa).

3.Drythelterelementusingwarm,owingairat

160degreesF(71degreesC)maximum,orallow

theelementtoair-dry.

Important:Donotusealightbulbtodrythe

lterelementbecausedamagecouldresult.

•Compressedairmethod:

1.Blowcompressedairfromtheinsidetothe

outsideofthedrylterelement.Keeptheair

hosenozzleatleast2inches(51mm)fromthe

lterandmovethenozzleupanddownwhile

rotatingthelterelement.

Important:Topreventdamagetothelter

element,donotexceed100psi(689kPa)air

pressure.

2.Inspectthelterelementforholesandtearsby

lookingthroughtheltertowardabrightlight.

InstallingtheFilterElement

ServiceInterval:Every200hours

Important:Topreventenginedamage,always

operatetheenginewiththecompleteaircleaner

assemblyinstalled.

1.Inspectthenewlterforshippingdamage.Check

thesealingendofthelter.

Important:Donotinstalladamagedlter.

2.Insertthenewlterintoaircleanerbody.Ensure

thelterissealedproperlybyapplyingpressureto

theouterrimofthelterwheninstallingit.Donot

pressontheexiblecenterofthelter.

3.Installthecoverandsecurethelatches.

InspectingtheCarbonCanisterAir

Filter

ServiceInterval:Aftertherst50hours

Every200hours

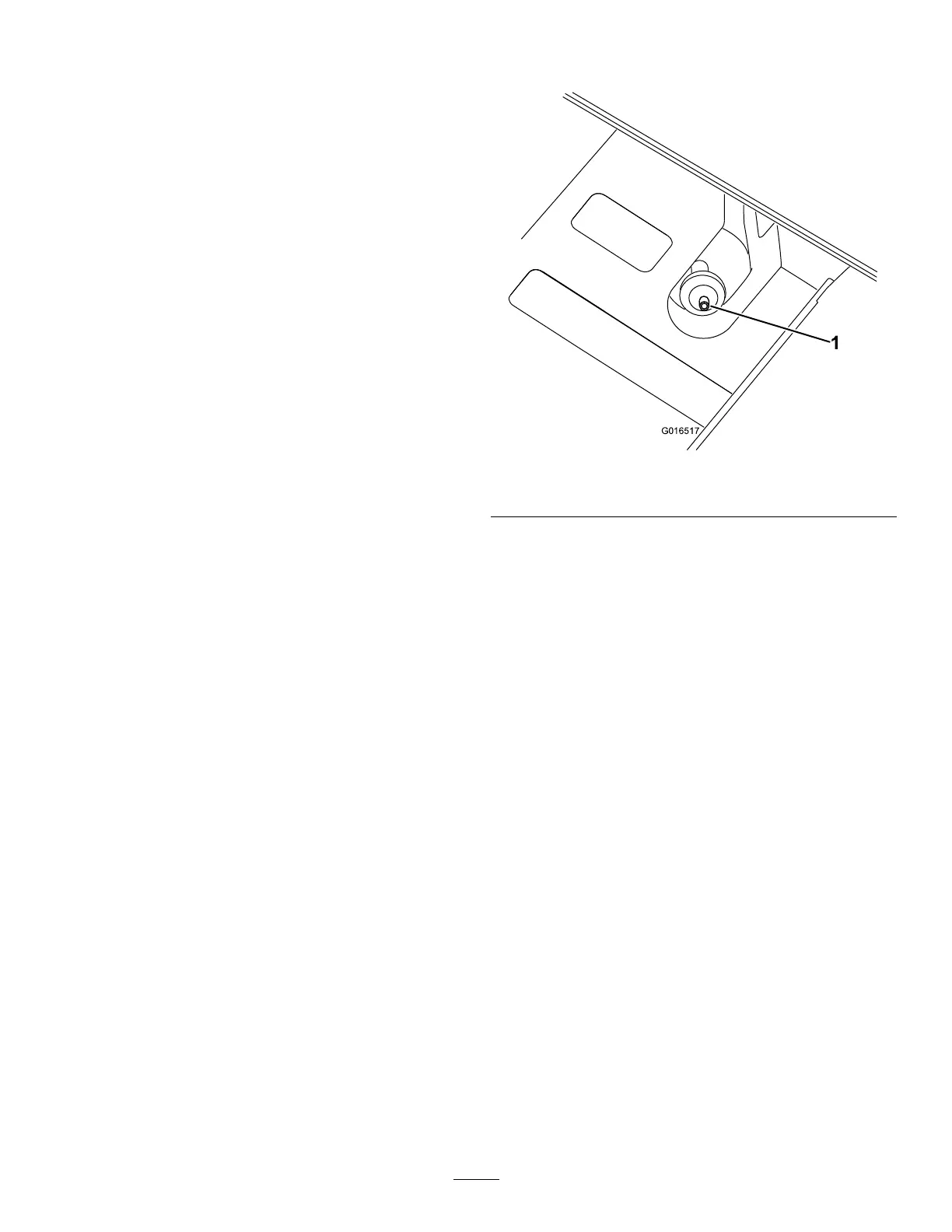

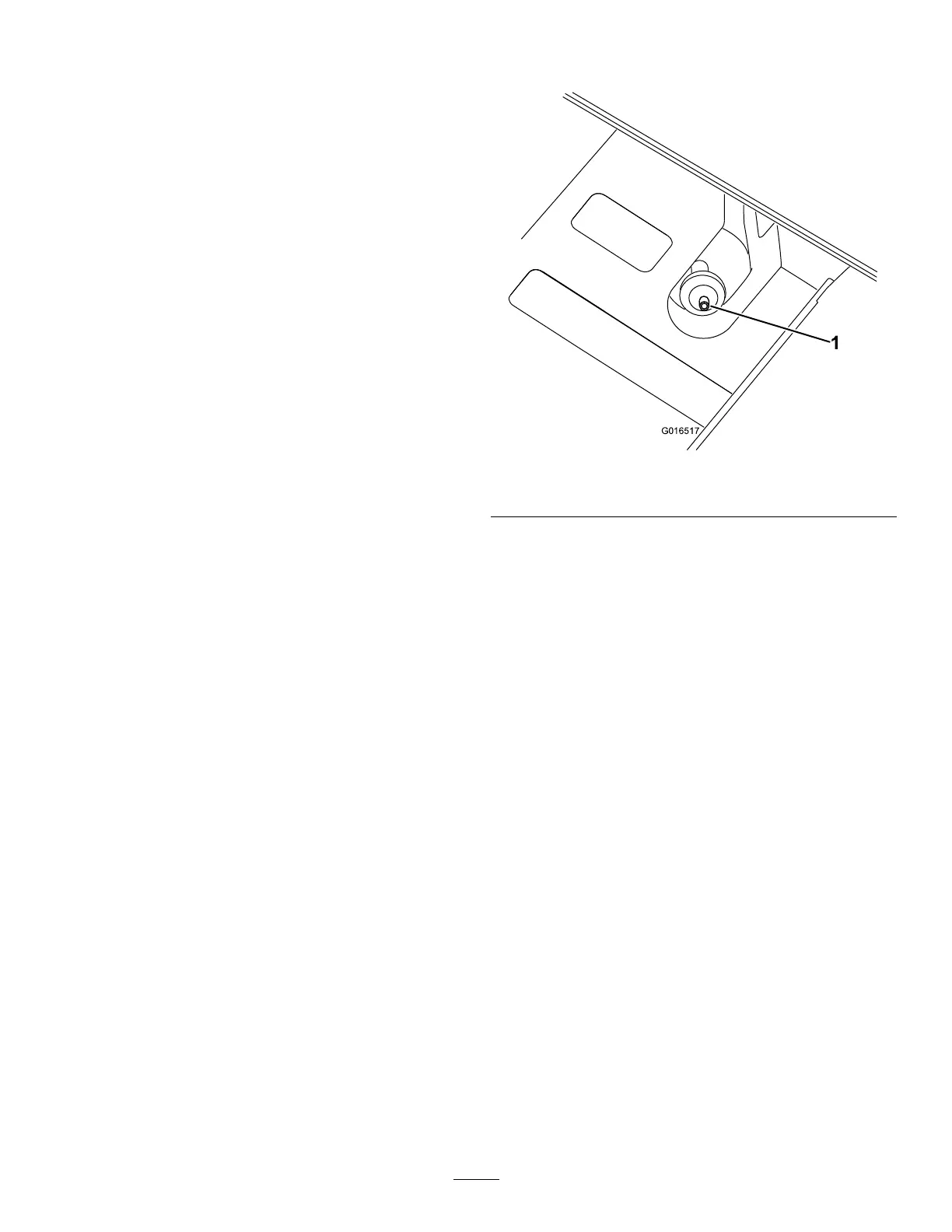

1.Locatetheairlteronthebottomofthecarbon

canister(Figure25).

Figure25

1.Filteropening

2.Ensurethattheopeningonthebottomofthelter

isclearandopen.

ServicingtheEngineOil

(Models07266/TCand07279

only)

Checktheoillevelbeforeeachuse.

Changetheoilaftertherst25operatinghoursand

every100operatinghoursthereafter.Changetheoil

twiceasofteninspecialoperatingconditions;refer

toMaintainingtheVehicleunderSpecialOperating

Conditions.

Note:Changetheoilmorefrequentlywhenoperating

conditionsareextremelydustyorsandy.

OilType:Detergentoil(APIserviceSJ,SK,SL,SM,

orhigher)

Viscosity:Seethefollowingtable.

25

Loading...

Loading...