JackingVehicle

Avehicleonajackmaybeunstableandslipoff

ofthejack,injuringanyonebeneathit.

•Donotstartthevehiclewhilethevehicleis

onajack.

•Alwaysremovethekeyfromtheswitch

beforegettingoffofthevehicle.

•Blockthetireswhenthevehicleisonajack.

1.Donotstartenginewhilevehicleisonjack,because

enginevibrationorwheelmovementcouldcause

vehicletoslipoffjack.

2.Donotworkundervehiclewithoutjackstands

supportingit.Thevehiclecouldslipoffjack,injuring

anyonebeneathit.

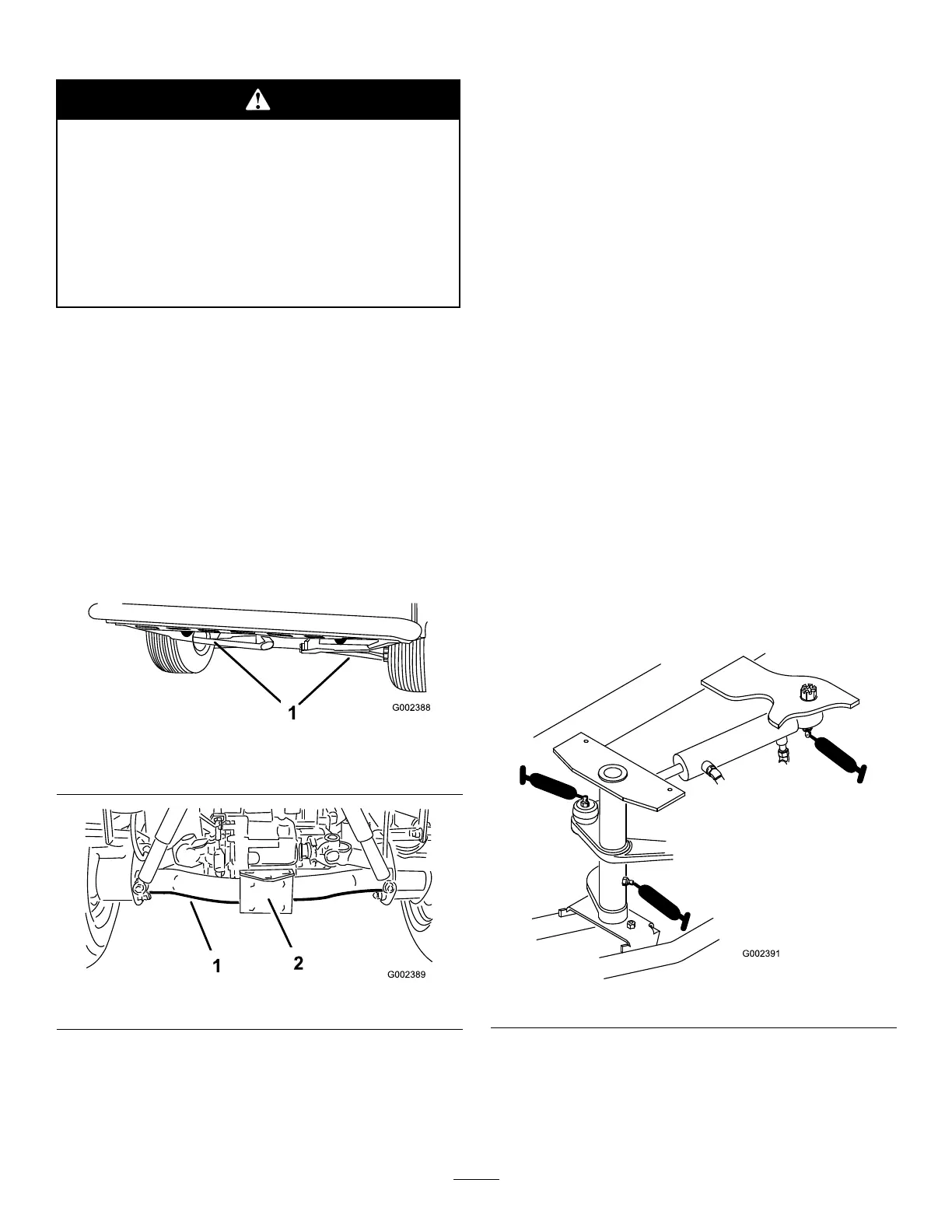

3.Thejackingpointatthefrontofthevehicleisunder

thefrontcenterframesupportandattherearitis

undertheaxletube.

4.Whenjackingupfrontofvehicle,alwaysplacea2x4

block(orsimilarmaterial)betweenjackandvehicle

frame.

Figure39

1.Frontjackingpoint

Figure40

Lubrication

GreasingBearingsand

Bushings

ServiceInterval:Every100hours

Thevehiclehasgreasettingsthatmustbelubricated

regularlywithNo.2GeneralPurposeLithiumBase

Grease.Ifmachineisoperatedundernormalconditions,

lubricateallbearingsandbushingsafterevery100hours

ofoperation.Morefrequentlubricationisrequiredif

usedforheavydutyvehicleoperations.

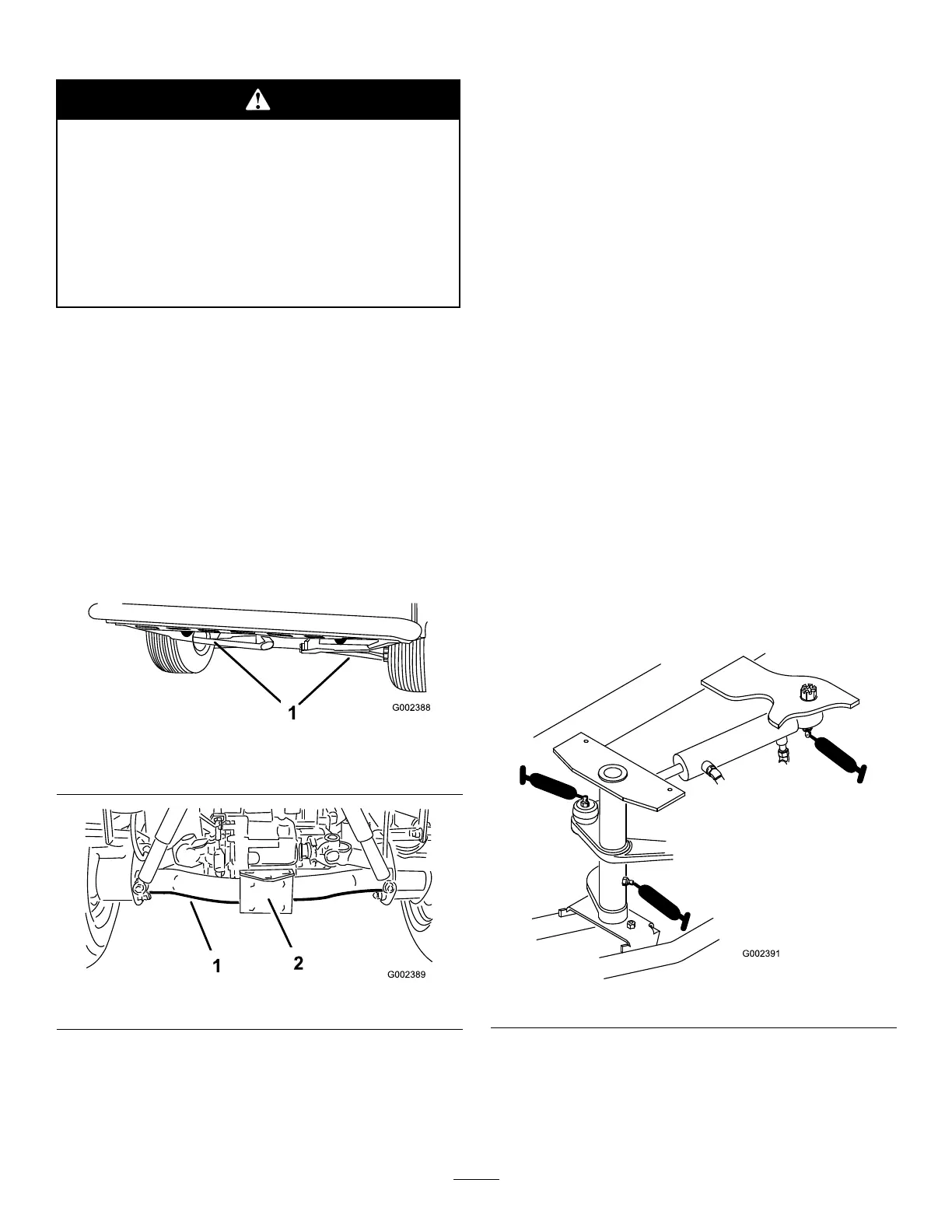

Thegreasettinglocationsandquantitiesare:Steering

pitmanarm(1)andSteeringballjointends(2)

(Figure41),Tierodends(4)(Figure42),Frontball

joints(4)(Figure42),Reardriveshafts(18)(Figure43),

Pedalpivots(3)(Figure44);Frontpivotbushings(2)

(Figure45)andAcceleratorarm(1)(Figure46).

Important:Whengreasingdriveshaftuniversal

shaftbearingcrosses,pumpgreaseuntilitcomes

outofall4cupsateachcross.

1.Wipegreasettingcleansoforeignmattercannotbe

forcedintothebearingorbushing.

2.Pumpgreaseintothebearingorbushing.

3.Wipeoffexcessgrease.

Figure41

39

Loading...

Loading...