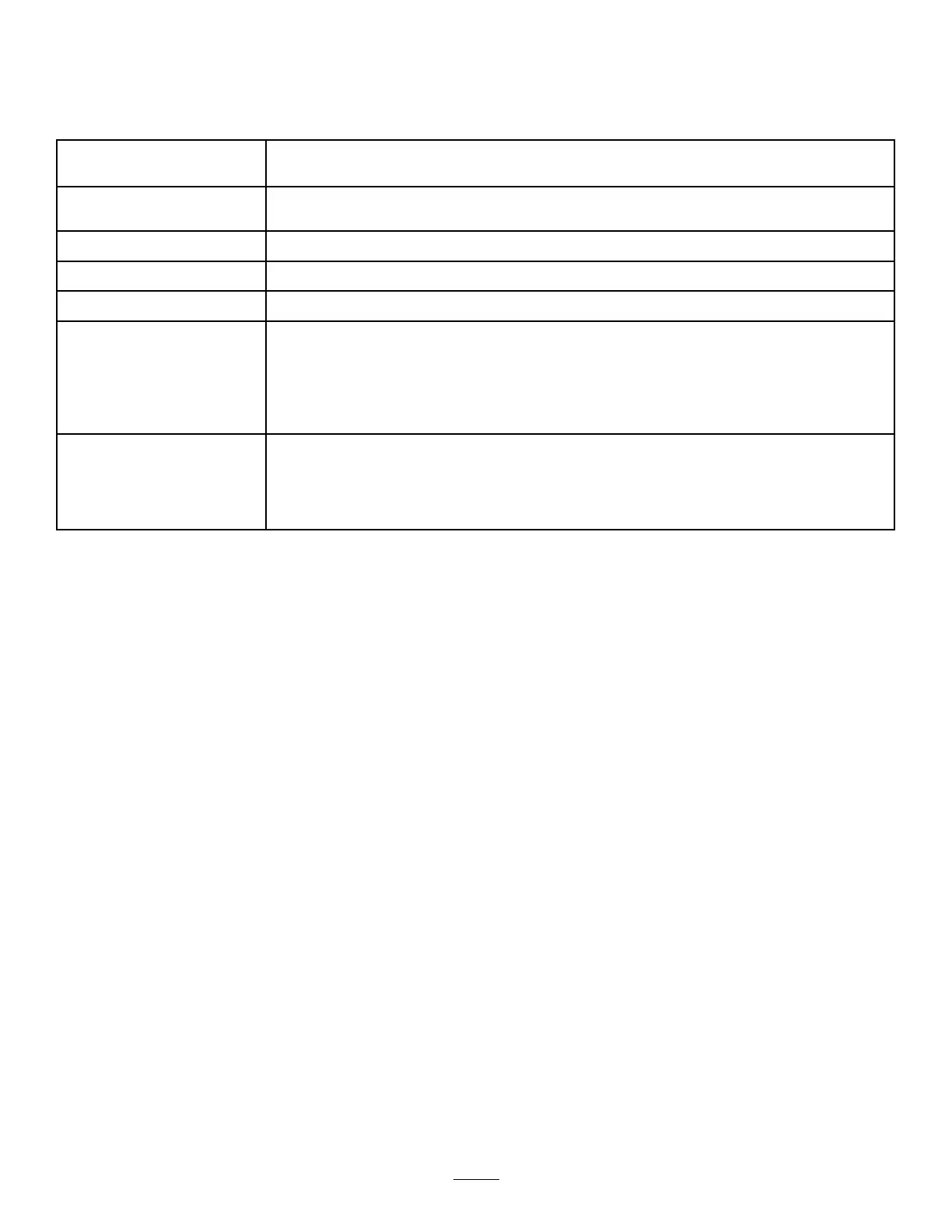

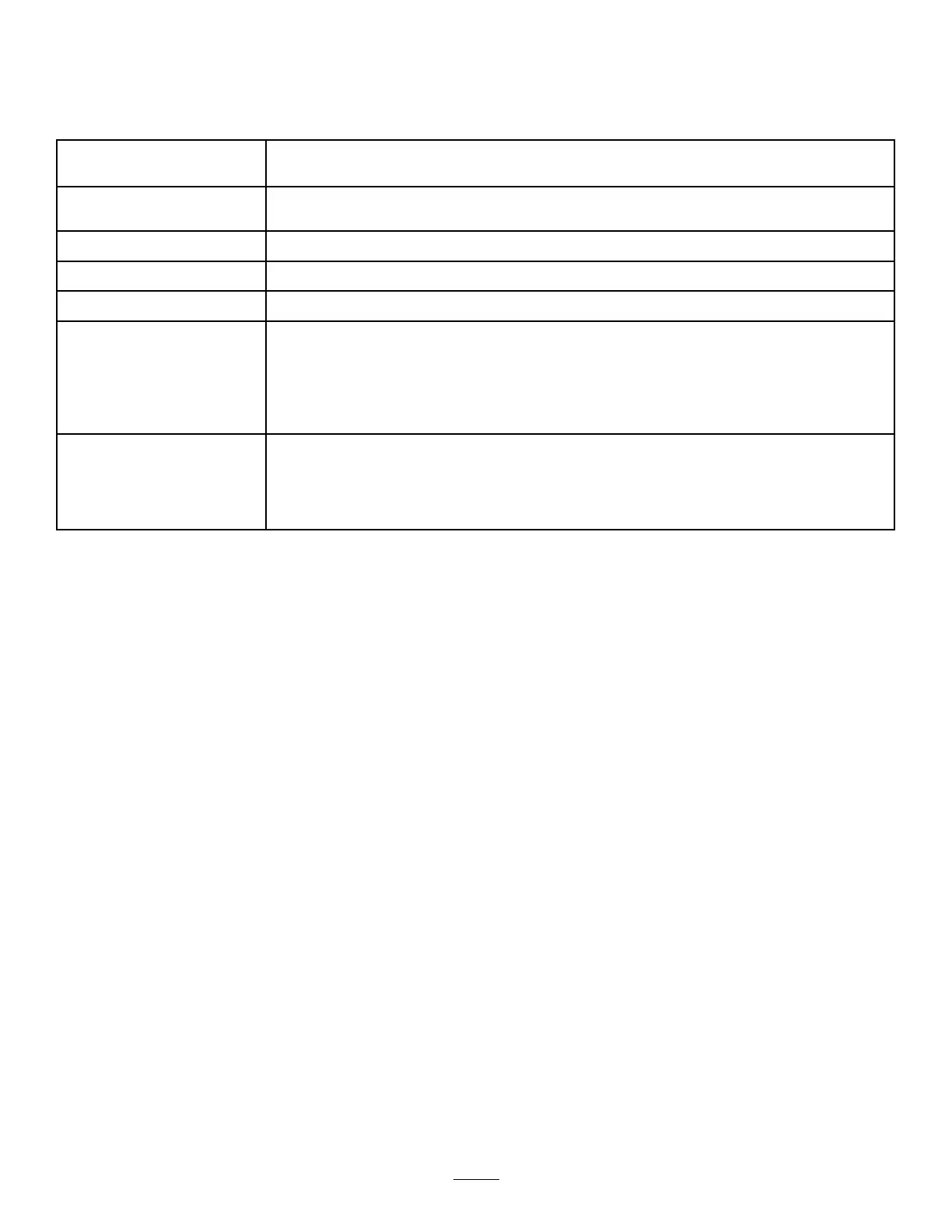

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Aftertherst2hours

•Inspectthetractioncableandadjustitifnecessary.

•Inspecttheauger/impellercableandadjustitifnecessary.

Aftertherst5hours

•Changetheengineoil.

Beforeeachuseordaily

•Checktheengine-oillevelandaddoilifnecessary.

Every100hours

•Replacethesparkplug.

Yearly

•Checktheskidsandthescraperandadjustthemifnecessary.

•Inspectthetractioncableandadjustorreplaceitifnecessary.

•Inspecttheauger/impellercableandadjustorreplaceitifnecessary.

•Checktheauger-gearboxoilandaddoilifnecessary.

•Changetheengineoil.

•Lubricatethehexshaft.

Yearlyorbeforestorage

•Checktheairpressureinthetiresandinatethemto116to137kPa(17to20psi).

•Drainthegasolineandruntheenginetodryoutthefueltankandthecarburetorat

theendoftheseason.

•HaveanAuthorizedServiceDealerinspectandreplacethetraction-drivebeltand/or

theauger/impellerdrivebelt,ifnecessary.

MaintenanceSafety

Readthefollowingsafetyprecautionsbefore

performinganymaintenanceonthemachine:

•Shutofftheengine,removethekey,andwait

forallmovementtostopbeforeyouleavethe

operator’sposition.Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

•Alwaysweareyeprotectionwhileperformingan

adjustmentorrepairtoprotectyoureyesfrom

foreignobjectsthatthemachinemaythrow.

•Checkallfastenersatfrequentintervalsforproper

tightnesstoensurethatthemachineisinsafe

workingcondition.

•Donotchangethegovernorsettingsontheengine.

PurchaseonlygenuineT ororeplacementparts

andaccessories.

PreparingforMaintenance

1.Movethemachinetoalevelsurface.

2.Shutofftheengine,removethekey,andwaitfor

allmovingpartstostop.

3.Disconnectthespark-plugwire.Referto

ReplacingtheSparkPlug(page24).

19

Loading...

Loading...