Note:Theamountofforceneededtocompressthe

leverincreasesnoticeablywhenyouremovetheslack

fromtheauger/impellerdrivebelt(approximately1/2

ofthelevermovement).Theadjustmentiscorrect

whentheforcebeginstoincreaseandthedistance

betweenthetopofthehandgripandthebottomofthe

auger/impellerdrivecontrolleveris1to2inches(3to

5cm)asshowninFigure9.

5.Toadjustthedistance:

A.Removetheclevispin.

B.Loosenthejamnut.

C.Threadtheclevisupordowntoincreaseor

decreasethedistancebetweenthetopofthe

handgripandthebottomoftheauger/impeller

drivecontrollever(

Figure8).

6.Whentheadjustmentiscorrect,installtheclevispin

andsecureitinplacewiththecotterpin(Figure8).

7.Tightenthejamnuttosecuretheclevis(Figure8).

5

InstallingtheChuteControl

Rod

Partsneededforthisprocedure:

1

Chutecontrolrodassembly(rodandbracket,worm

gear,andbracket)

1Bellevillewasher

2Bolt

1

Carriagebolt

3Locknut

1

Curvedwasher

Procedure

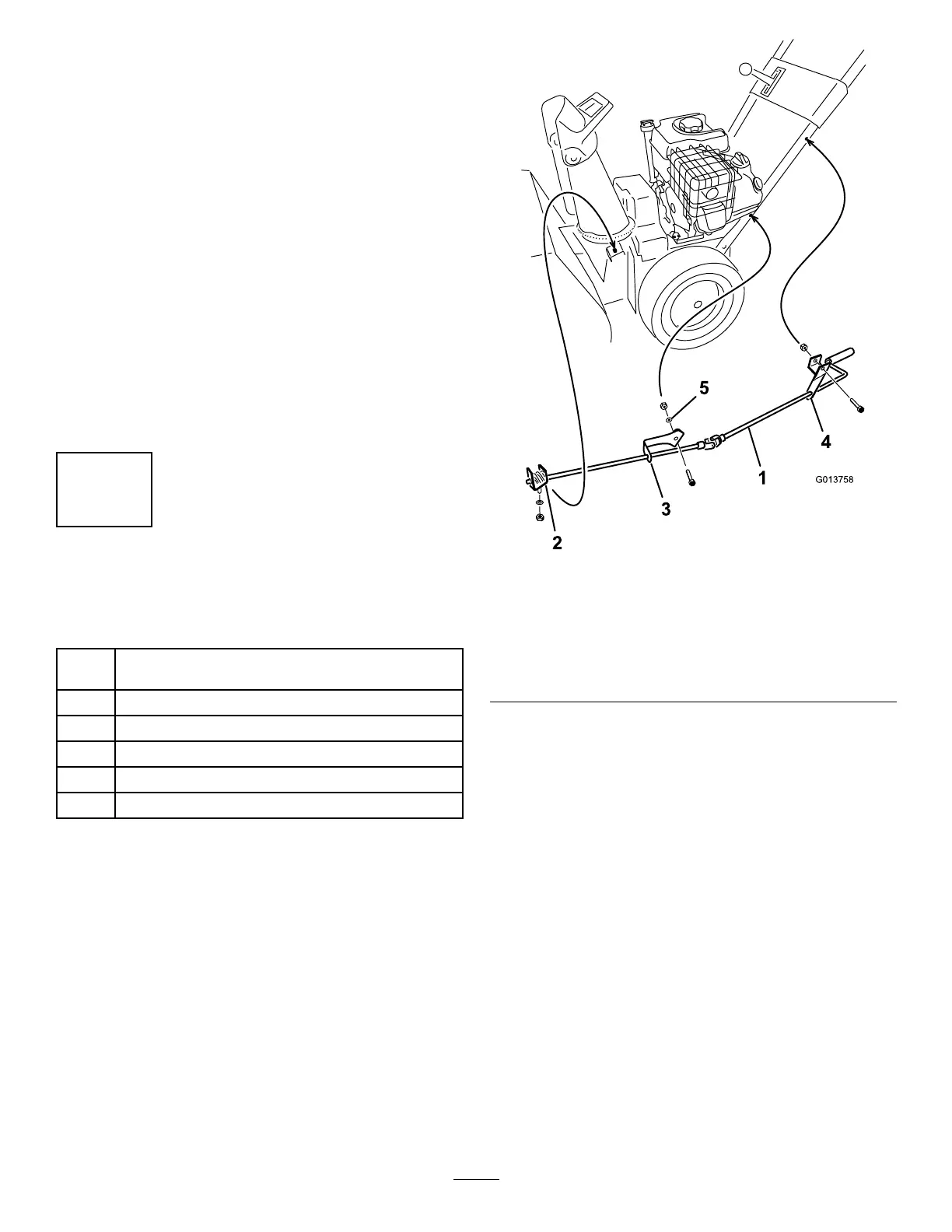

1.Securetheupperchutecontrolbracket(attachedtothe

chutecontrolrod)totheupperleftsideofthehandle

withaboltandalocknut

Figure10.

Figure10

1.Chutecontrolrod

4.Upperchutecontrol

bracket

2.Wormgear,bracket,and

mountingange

5.Curvedwasher

3.Lowerchutecontrol

bracket

Note:Leavethelocknutloose.

2.Securethelowerchutecontrolbracket(attachedtothe

chutecontrolrod)tothelowerleftsideofthehandle

withabolt,acurvedwasher,aatwasher,andalocknut

(Figure10).

Note:Thebracketshouldbefastenedontheoutside

ofthehandle,andtherodshouldbeapproximately

paralleltothegroundandnottouchthehandle.

Note:Leavethelocknutloose.

3.ApplyNo.2generalpurposegreasetothewormgear

(

Figure11).

12

Loading...

Loading...