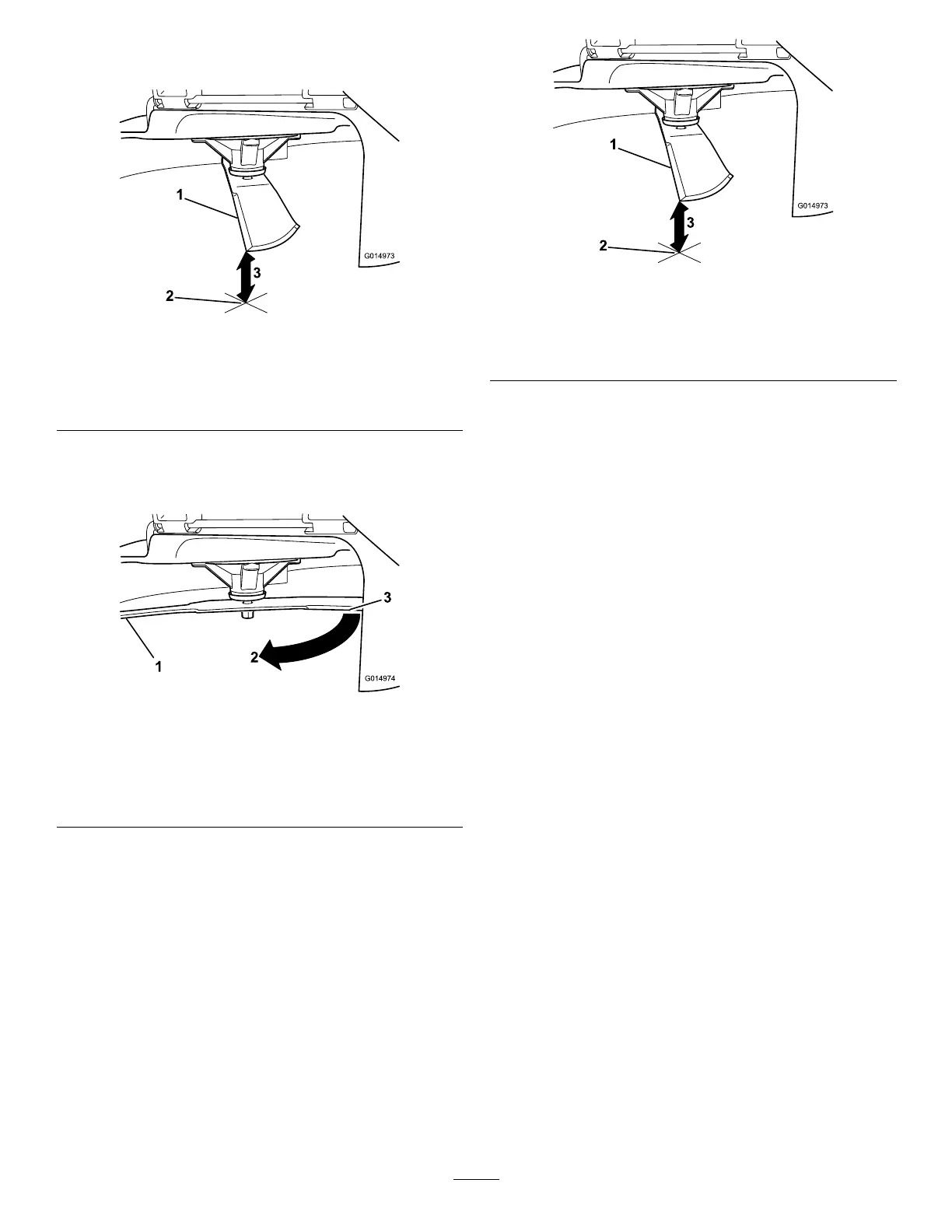

3.Measurefromthetipofthebladetotheat

surface(Figure44).

g014973

Figure44

1.Blade(inpositionformeasuring)

2.Levelsurface

3.Measureddistancebetweenbladeandthesurface(A)

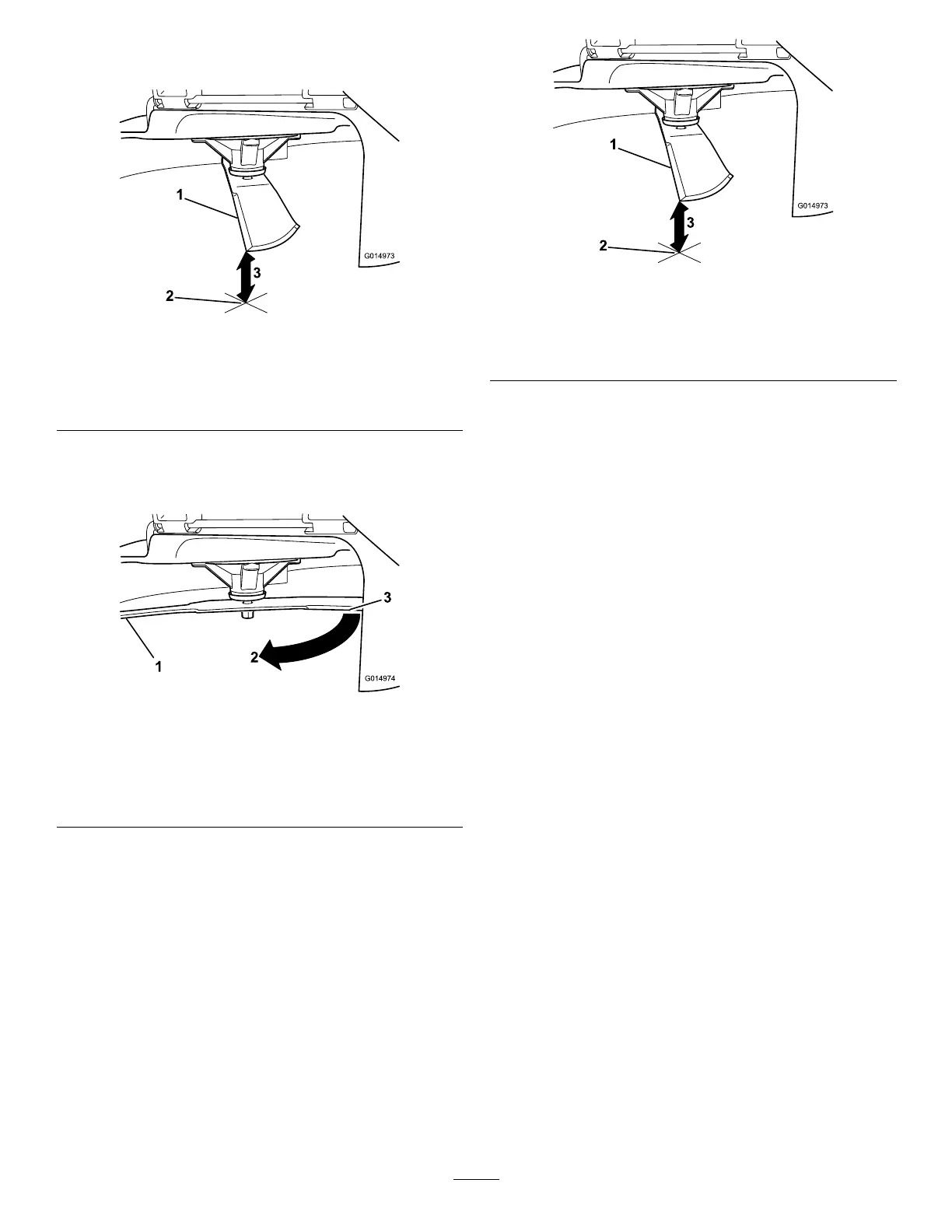

4.Rotatethesameblade180degrees,sothat

theopposingcuttingedgeisnowinthesame

position(Figure45).

g014974

Figure45

1.Blade(sidepreviouslymeasured)

2.Measurement(positionusedpreviously)

3.Opposingsideofbladebeingmovedintomeasurement

position

5.Measurefromthetipofthebladetotheat

surface(Figure46).

Note:Thevarianceshouldbenomorethan

3mm(1/8inch).

g014973

Figure46

1.Oppositebladeedge(inpositionformeasuring)

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

A.IfthedifferencebetweenAandBisgreater

than3mm(1/8inch),replacethebladewith

anewblade;refertoRemovingtheBlades

(page41).

Note:Ifabentbladeisreplacedwithanew

one,andthedimensionobtainedcontinues

toexceed3mm(1/8inch),thebladespindle

couldbebent.ContactanAuthorizedToro

Dealerforservice.

B.Ifthevarianceiswithinconstraints,moveto

thenextblade.

Repeatthisprocedureoneachblade.

RemovingtheBlades

Thebladesmustbereplacedifasolidobjectishit,if

thebladeisoutofbalance,orifthebladeisbent.To

ensureoptimumperformanceandcontinuedsafety

conformanceofthemachine,usegenuineT oro

replacementblades.Replacementbladesmadeby

othermanufacturersmayresultinnon-conformance

withsafetystandards.

1.Holdthebladeendusingaragorthickly-padded

glove.

2.Removethebladebolt,curvedwasher,and

bladefromthespindleshaft(Figure47).

41

Loading...

Loading...