CHECK THE CRANKCASE OIL

The engine is shipped with 3.7 quarts (3.5 L) of oil in the

crankcase; however, the level of the oil must be checked before

and after the engine is first started.

1. Position the machine on a level surface.

2. Disengage the hood latch and open the hood.

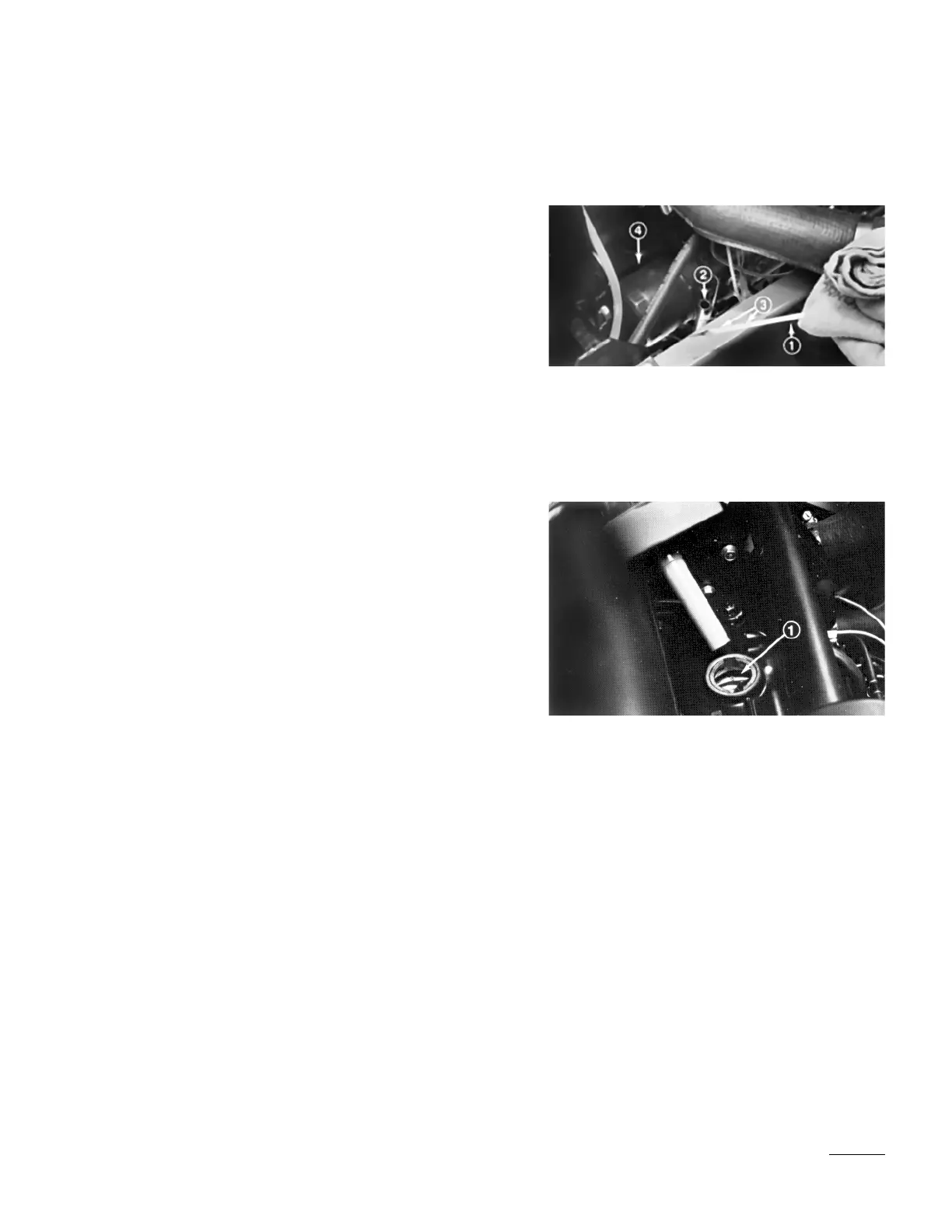

3. Remove the dipstick and wipe it with a clean cloth (Fig. 1).

Push the dipstick down into the tube and ensure it is fully

seated. Pull the dipstick out of the tube and check the

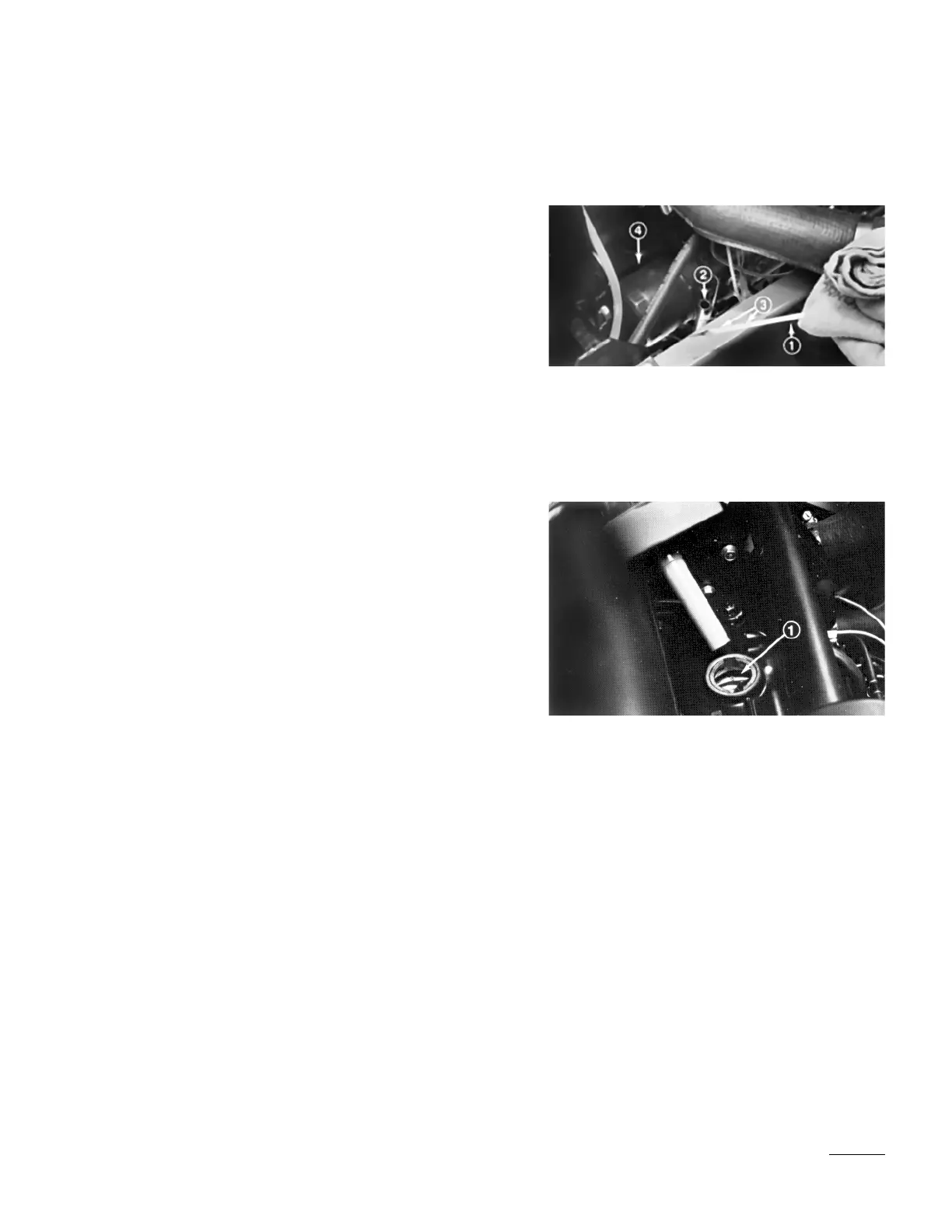

level of the oil. If the oil level is low, remove the filler cap

(Fig. 2) and add enough oil to raise the level to the top

notch on the dipstick (Fig. 1). DO NOT OVERFILL.

4. The engine uses any high-quality detergent having the

American Petroleum institute—API—“service classifica-

tion” SF/CC or CD. Oil viscosity recommendations are:

SAE 10W-30.

IMPORTANT: Check the oil level after every 5 hours

of operation or daily. Change the oil after every 50

hours of operation and change the oil filter after the

first 50 hours and every 100 hours thereafter. Change

the oil and filter more frequently when the engine is

operated in extremely dusty or dirty conditions.

5. Install the dipstick into tube.

FILL THE FUEL TANK WITH DIESEL

FUEL

The engine runs on No. 1-D or 2-D automotive type diesel fuel

with a minimum octane rating of 40.

Note: Higher octane rated fuel may be required if you use the

machine at high altitudes and low atmospheric temperatures.

Use No. 2-D diesel fuel at temperatures above 20° F (–7° C)

and No. 1-D diesel fuel below 20° F (–7° C). Number. 1-D

diesel fuel at lower temperatures provides a lower flash point

and pour point characteristics, therefore easing startability and

lessening chances of chemical separation of the fuel because of

Figure 1

1. Dipstick

2. Dipstick tube

3. Keep oil level between notches

4. Engine oil filter

Figure 2

1. Oil fill hole

11

Before Operating

Loading...

Loading...