AdjustingtheControlCable

CheckingtheControlCable

ServiceInterval:Afterthersthour—Checkthecontrol

cableandadjustitifnecessary.

Yearly—Checkthecontrolcableandadjustitif

necessary.

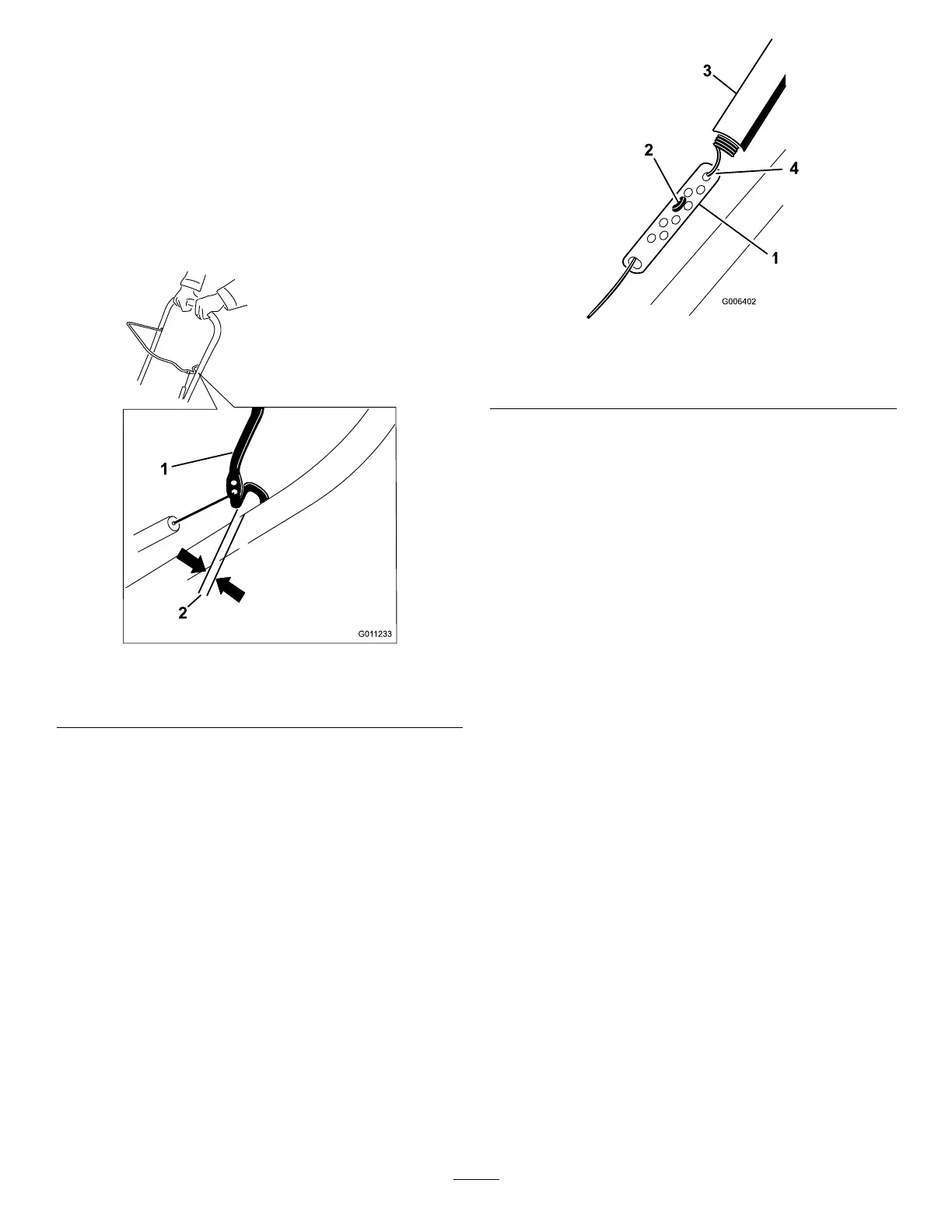

Movethecontrolbarbacktowardthehandletoremovethe

slackinthecontrolcable(Figure25).

Figure25

1.Controlbar2.1/16-inchto1/8-inch(2

mmto3mm)gap

Note:Ensurethata1/16-inchto1/8-inch(2mmto3mm)

gapexistsbetweenthecontrolbarandthehandle(Figure25).

Important:Thecontrolcablemustcontainsomeslack

whenyoudisengagethecontrolbarfortherotorblades

tostopproperly.

AdjustingtheControlCable

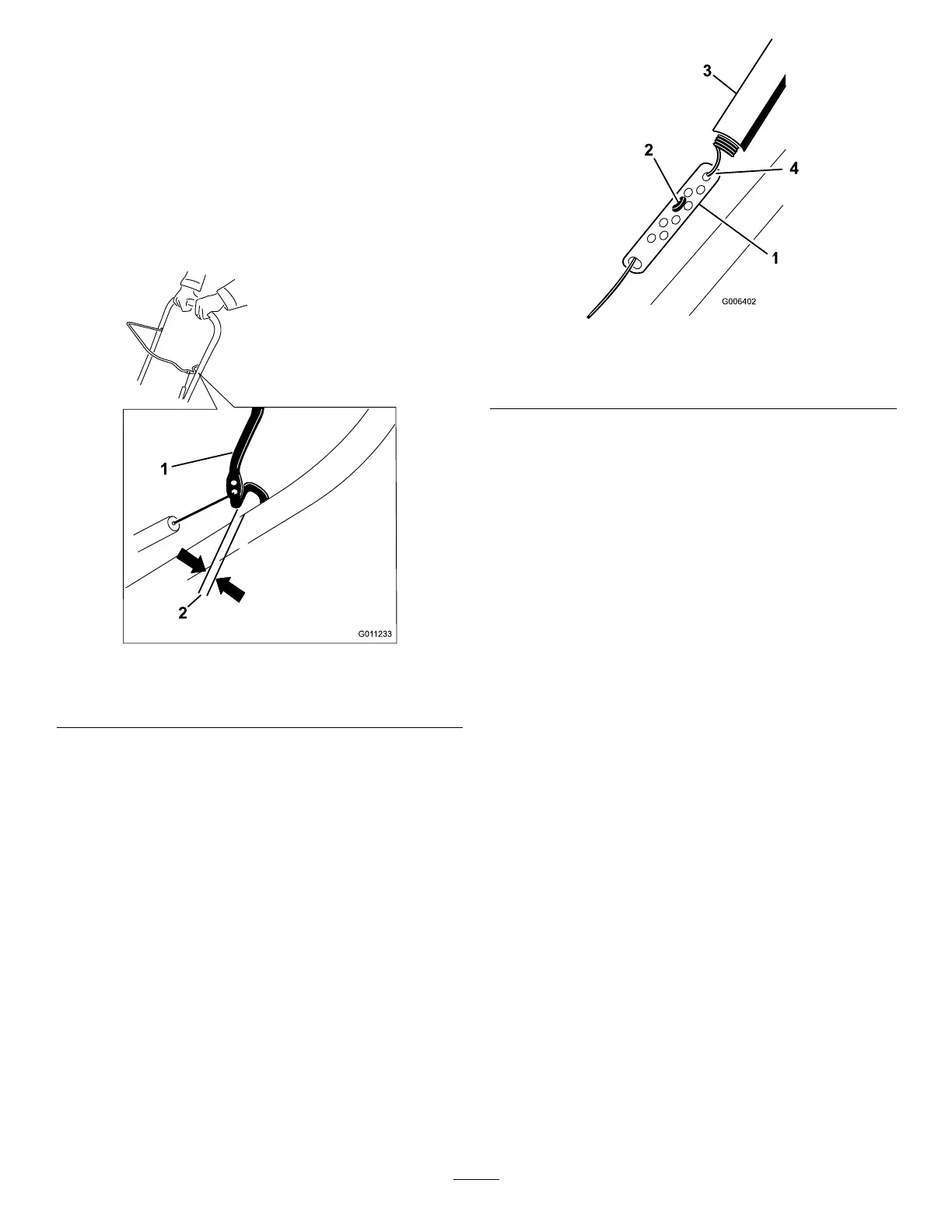

1.Slideupthespringcoverandunhookthespringfrom

theadjusterlink(Figure26).

Figure26

1.Adjusterlink

3.Springcover

2.Z-tting

4.Unhookthespringhere.

Note:Youcanpulluptheadjusterlinkandcableto

makeunhookingthespringeasier.

2.MovetheZ-ttingtoahigherorlowerholeonthe

adjusterlinkasneededtoobtainthe1/16-inchto

1/8-inch(2mmto3mm)gapbetweenthecontrolbar

andthehandle(Figure26).

Note:MovingtheZ-ttinghigherdecreasesthegap

betweenthecontrolbarandthehandle;movingit

lowerincreasesthegap.

3.Hookthespringtotheadjusterlinkandslidethespring

coverovertheadjusterlink.

4.Checktheadjustment;refertoCheckingtheControl

Cable.

Note:Afterextendeduse,thedrivebeltmaywear

andloseitsproperbelttension.Ifthedrivebeltslips

(continuouslysqueals)underaheavyload,disconnect

thespringfromtheadjustorlinkandmovetheupper

endofthespringtotheholethatisfurtherfrom

thepivotpointinthecontrolbar(Figure27).Then

connectthespringtotheadjustorlinkandadjustthe

controlcable.

13

Loading...

Loading...