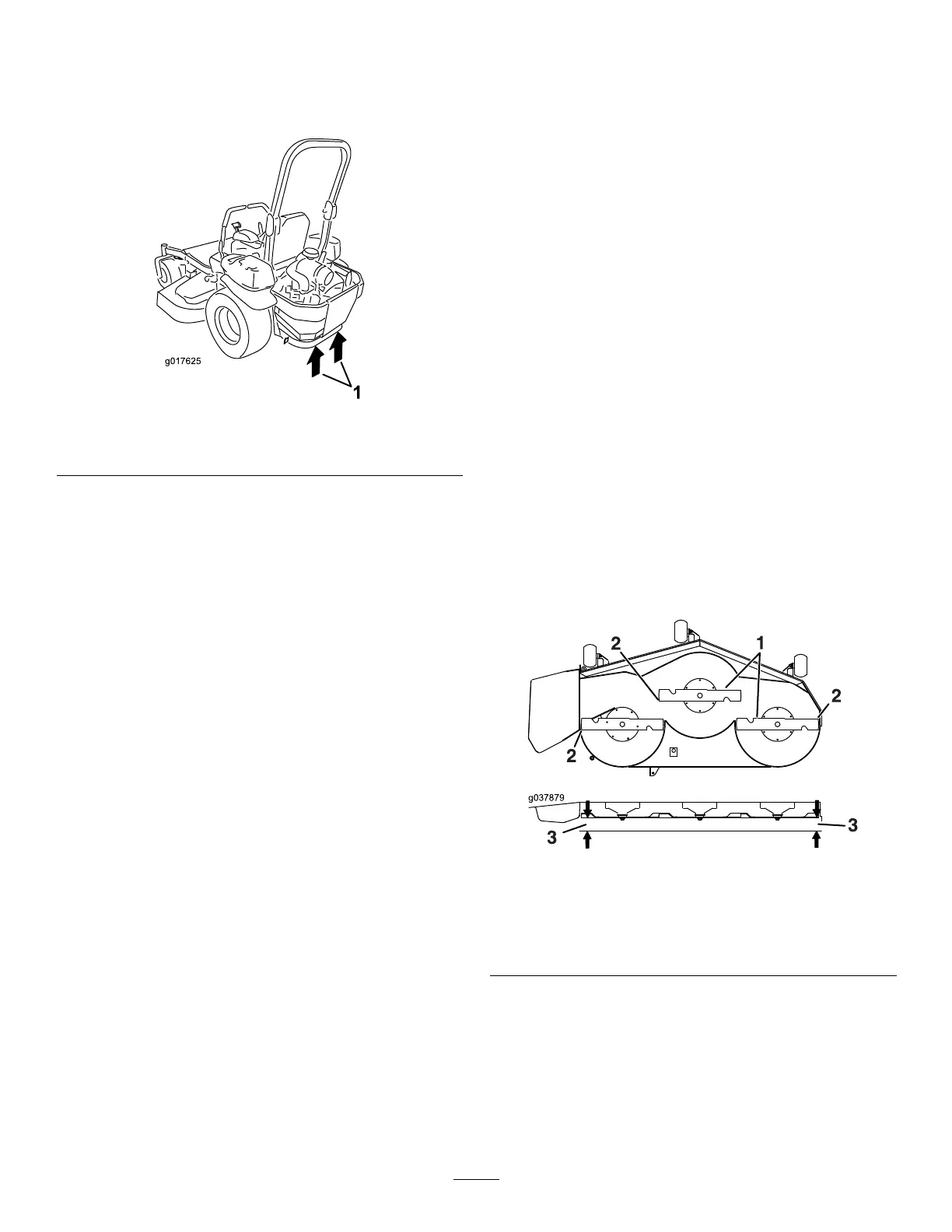

BleedingtheHydraulicSystem

1.Raisetherearofmachineandsupportitwith

jackstands(orequivalentsupport)justhigh

enoughtoallowthedrivewheelstoturnfreely.

g017625

Figure100

1.Jackingpoints

2.Starttheengine,movethethrottlecontrolahead

tothe1/2throttleposition,anddisengagethe

parkingbrake.

A.Movethebypassleversintothepushingthe

machineposition.Withthebypassvalves

openandtheenginerunning,slowlymove

themotion-controlleversinbothforward

andreverse5or6times.

B.Movethebypassleversintotheoperating

themachineposition.

C.Withthebypassvalveclosedandthe

enginerunning,slowlymovethecontrol

leverinbothforwardandreversedirections

5to6times.

D.Shutofftheengineandchecktheoillevelin

theexpansionreservoir.Addthespecied

oiluntilitreachestheFULLCOLDlineonthe

expansionreservoir.

3.Repeatstep2untilalltheairiscompletely

purgedfromthesystem.

Note:Whenthetransaxleoperatesatnormal

noiselevels,movessmoothlyforward,and

reversesatnormalspeeds,itispurged.

4.Checktheoillevelintheexpansionreservoira

naltime.Addthespeciedoilasuntilitreaches

theFULLCOLDlineontheexpansionreservoir.

MowerDeck

Maintenance

LevelingtheMowerDeck

AdjustingtheSide-to-Side

LevelingandtheBladeSlope

1.Positionthemoweronaatsurface.

2.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andsettheparkingbrake.

3.Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

4.Checkthetirepressureinthedrivetires.Refer

toCheckingtheTirePressure(page60).

5.Positionthemowerdeckinthetransport-lock

position.

6.Carefullyrotatethebladesfromsidetoside.

7.Measurebetweenthebladetipandtheat

surface(Figure101).Ifbothmeasurementsare

notwithin5mm(3/16inch),adjusttheleveling;

continuewiththisprocedure.

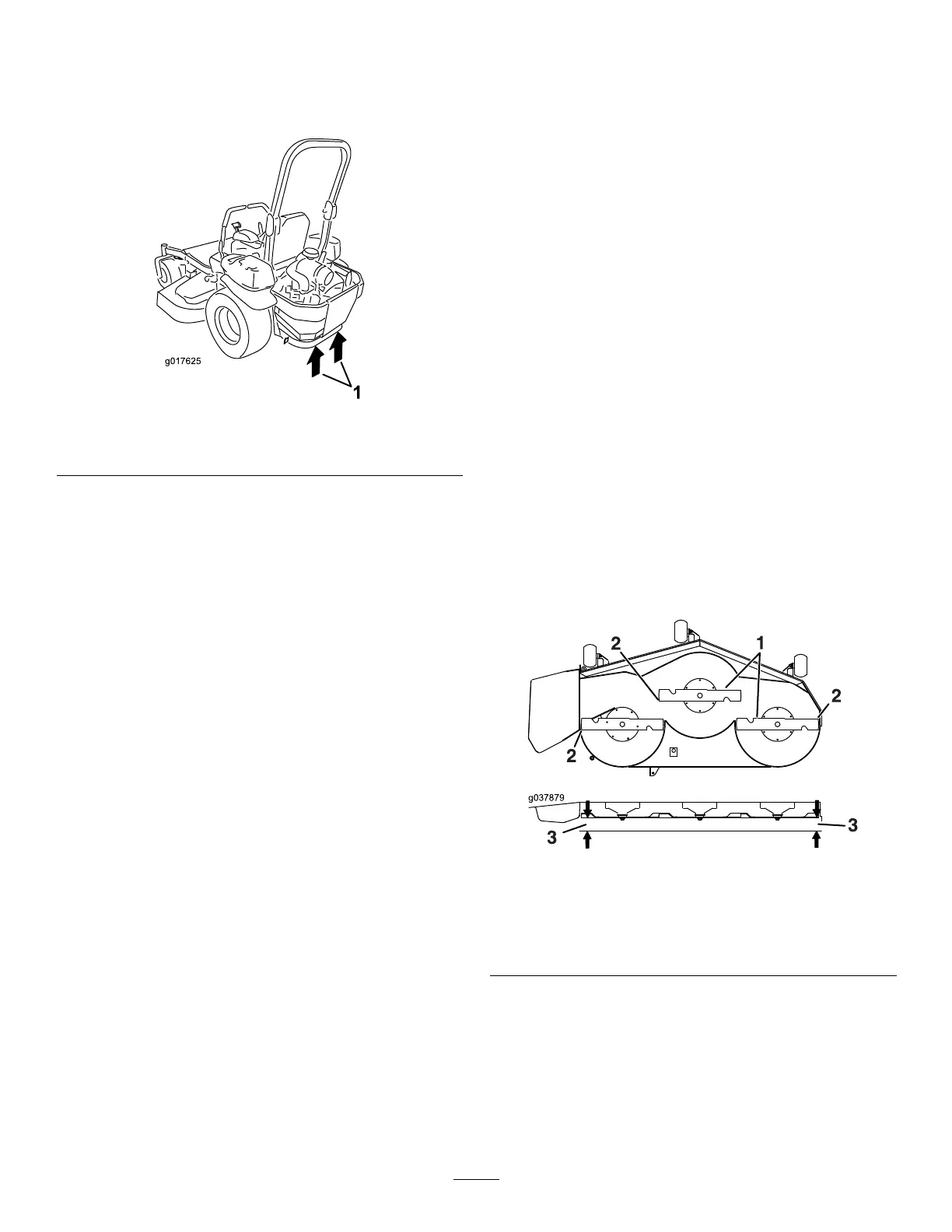

g037879

Figure101

1.Bladessidetoside

3.Measurefromthetipofthe

bladetotheatsurface

here.

2.Bladetip

8.Checkthefront-to-rearbladelevel(Figure102).

Ensurethefrontbladetipislowerthantherear

bladetipasshownintheblockheightandrake

table.Ifadjustmentisneeded,continuewiththis

procedure.

72

Loading...

Loading...