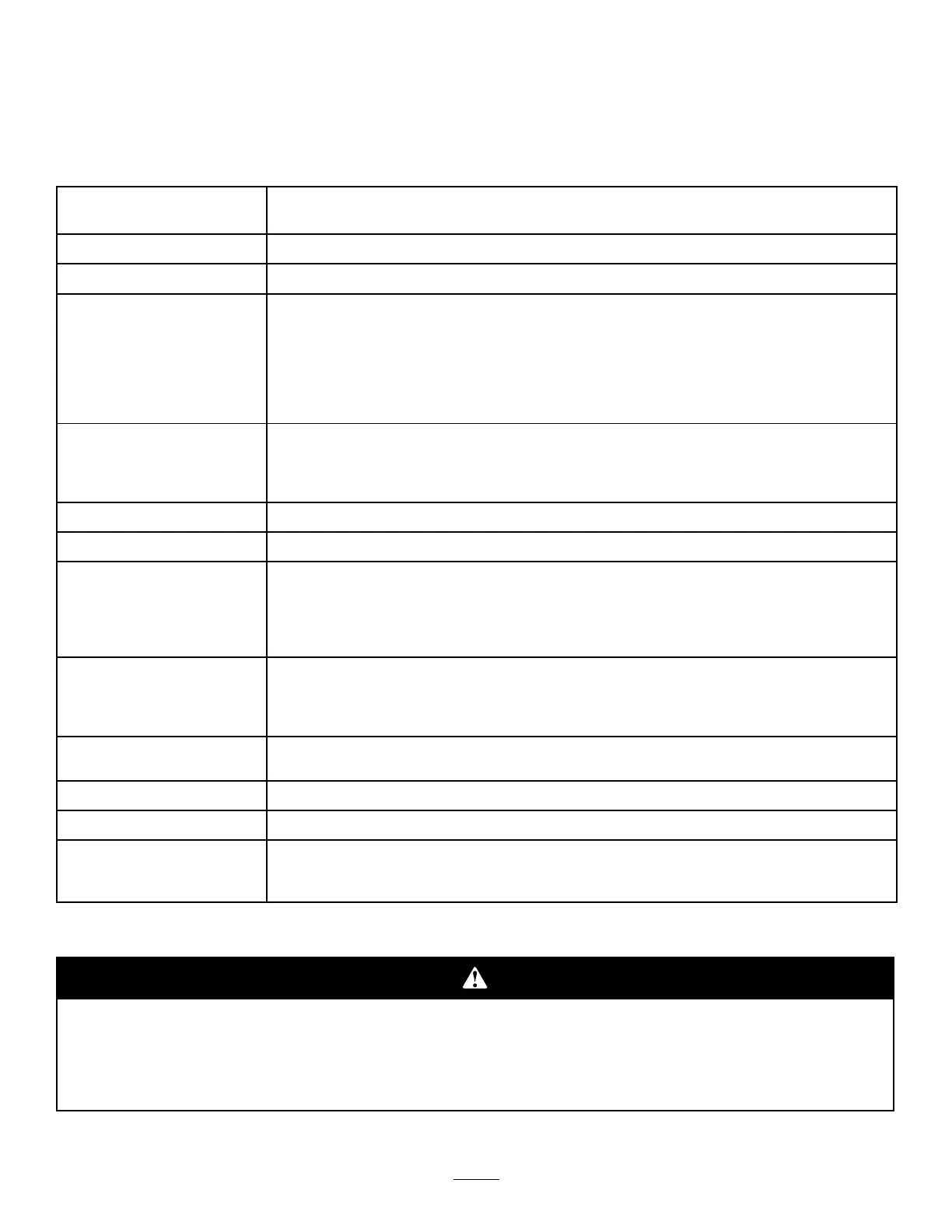

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Aftertherst8hours

•Changetheengineoil.

Aftertherst50hours

•Checkandadjustthetracktension.

Beforeeachuseordaily

•Checktheengineoillevel.

•Greasethemachine.(Greaseimmediatelyaftereverywashing.)

•Checktheengineoillevel.

•Checktheconditionofandcleanthetracks.

•Checktheconditionofthediggingteethandreplaceanythatarewornordamaged.

•Removedebrisfromthemachine.

•Checkforloosefasteners.

Every25hours

•Checkthehydraulicuidlevel.

•Cleanthefoamaircleanerelement.(Models22970and22971)

•Checkthebatteryelectrolytelevel.

•Checkthediggingchainforexcessivewearandpropertension.

Every40hours

•Greasethetrencherhousing.

Every50hours

•Checkthepaperaircleanerelement.(Models22970and22971)

Every100hours

•Changetheengineoil.

•Checkthesparkplugs.

•Checkandadjustthetracktension.

•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,weather,andchemicaldeteriorationandrepairifnecessary.

Every200hours

•Replacethepaperaircleanerelement.(Models22970and22971)

•Changetheoillter.

•Replacethefuellter.

•Replacethehydrauliclter.

Every250hours

•Replacetheprimaryairlterandcheckthecondtionofthesafetylter(Model22974)

•Checkandgreasetheroadwheels.

Every400hours

•Changethehydraulicuid.

Every1,500hours

•Replaceallmovinghydraulichoses.

Yearlyorbeforestorage

•Checkandadjustthetracktension.

•Checkandadjustthechaintension.

•Touchupchippedpaint

Important:Refertoyour

Engine Operator’ s Man ual

foradditionalmaintenanceprocedures.

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

22

Loading...

Loading...