– 2 –

EN

ID

ID

Safety Manual

11111

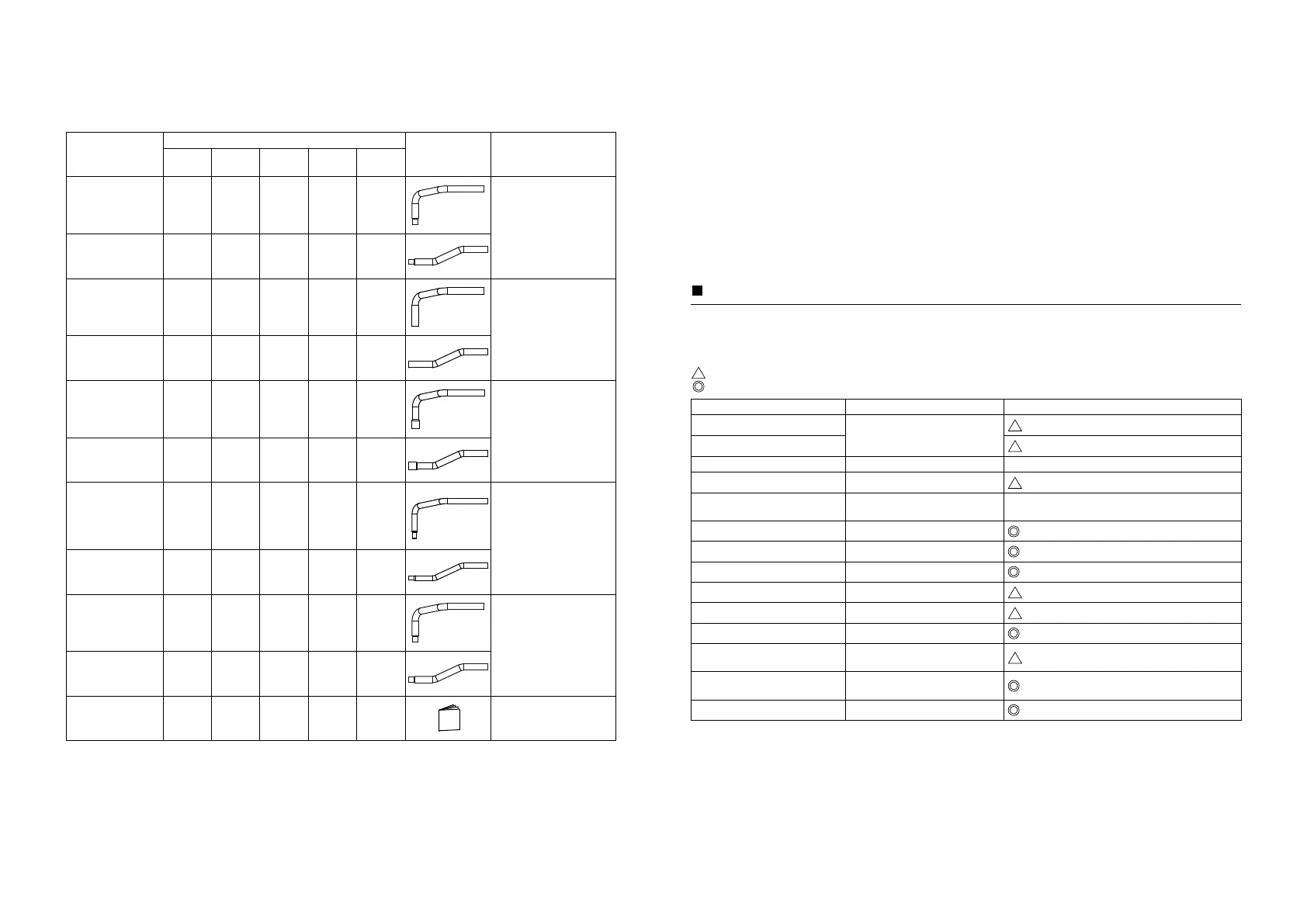

Part name

Q’ty

Shape Usage

MAP080

MAP100

MAP120 MAP140 MAP160

MAP180

MAP200

Attached pipe

(Ø12.7 for draw-out

forward)

–111–

Liquid pipe

Ø15.9ĺØ12.7 pipe fitting

* Flare the connector

on the outdoor unit for

installation.

Attached pipe

(Ø12.7 for draw-out

downward)

–111–

Attached pipe

(Ø15.9 for draw-out

forward)

––1–1

Liquid pipe

* Flare the connector

on the outdoor unit for

installation.

Attached pipe

(Ø15.9 for draw-out

downward)

––1–1

Attached pipe

(Ø19.1 for draw-out

forward)

–––11

Liquid pipe

Ø15.9ĺØ19.1 pipe fitting

* Flare the connector

on the outdoor unit for

installation.

Attached pipe

(Ø19.1 for draw-out

downward)

–––11

Attached pipe

(Ø9.5 for draw-out

forward)

1––––

Liquid pipe

Ø12.7ĺØ9.5 pipe fitting

* Flare the connector

on the outdoor unit for

installation.

Attached pipe

(Ø9.5 for draw-out

downward)

1––––

Attached pipe

(Ø9.5 for draw-out

forward)

–1–––

Liquid pipe

For hand over directly

to the customer.

Ø15.9ĺØ9.5 pipe fitting

* Flare the connector

on the outdoor unit for

installation.

Attached pipe

(Ø9.5 for draw-out

downward)

–1–––

2 Installation of new refrigerant air conditioner

This air conditioner adopts the new HFC refrigerant (R410A) which does not deplete the ozone layer.

R410A refrigerant is vulnerable to impurities such as water, oxidizing membranes, or oils because the pressure

of R410A refrigerant is higher than that of the former refrigerant by approximately 1.6 times.

As well as the adoption of the new refrigerant, the refrigerating oil has been also changed. Therefore, pay

attention so that water, dust, former refrigerant, or refrigerating oil does not enter the refrigerating cycle of the

new refrigerant air conditioner during installation.

To prevent mixing of refrigerant or refrigerating oil, the size of the charge port of the main unit or connecting

section of the installation tool differs to that of an air conditioner for the former refrigerant.

Accordingly, exclusive tools are required for the new refrigerant (R410A) as shown below.

For connecting pipes, use new and clean piping materials so that water or dust does not enter.

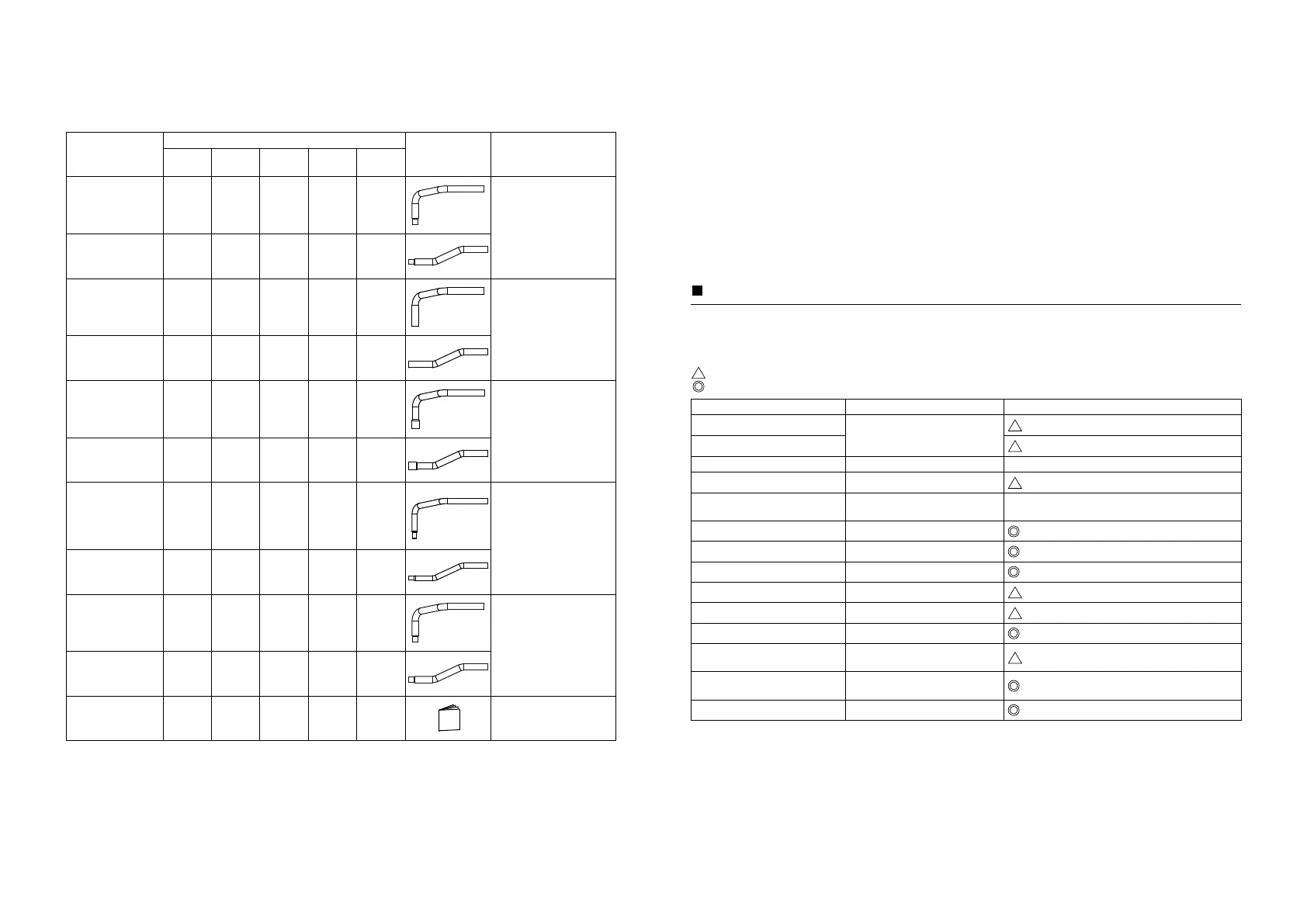

Required tools and cautions on handling

It is necessary to prepare the tools and parts for installation as described below. The tools and parts which will be

newly prepared in the following items should be restricted to exclusive use.

Explanation of symbols

: Newly prepared (It is necessary to use it exclusively with R410A, separately from those for R22 or R407C.)

: Former tool is available.

strap/sloot fo esu reporPegasUsloot desU

Gauge manifold

Vacuuming, charging refrigerant

and operation check

Exclusive to R410A

Charging hose

Exclusive to R410A

Charging cylinder Charging refrigerant Unusable (Use the Refrigerant charging balance.)

Gas leak detector Checking gas leak

Exclusive to R410A

Vacuum pump Vacuum drying

Usable if a counter-flow preventive adapter is

attached

Vacuum pump with counterflow Vacuum drying

R22 (Existing article)

sepip fo gnissecorp eralFloot eralF

Usable by adjusting size

sepip fo gnissecorp gnidneBredneB

R22 (Existing article)

Refrigerant recovery device Recovering refrigerant

Exclusive to R410A

Torque wrench Tightening flare nut

Exclusive to Ø12.7 mm and Ø15.9 mm

sepip gnittuCrettuc epiP

R22 (Existing article)

Refrigerant canister Charging refrigerant

Exclusive to R410A

Enter the refrigerate name for identification

Brazing machine/Nitrogen gas

cylinder

Brazing of pipes

R22 (Existing article)

Refrigerant charging balance Charging refrigerant

R22 (Existing article)

3-EN 4-EN

Loading...

Loading...