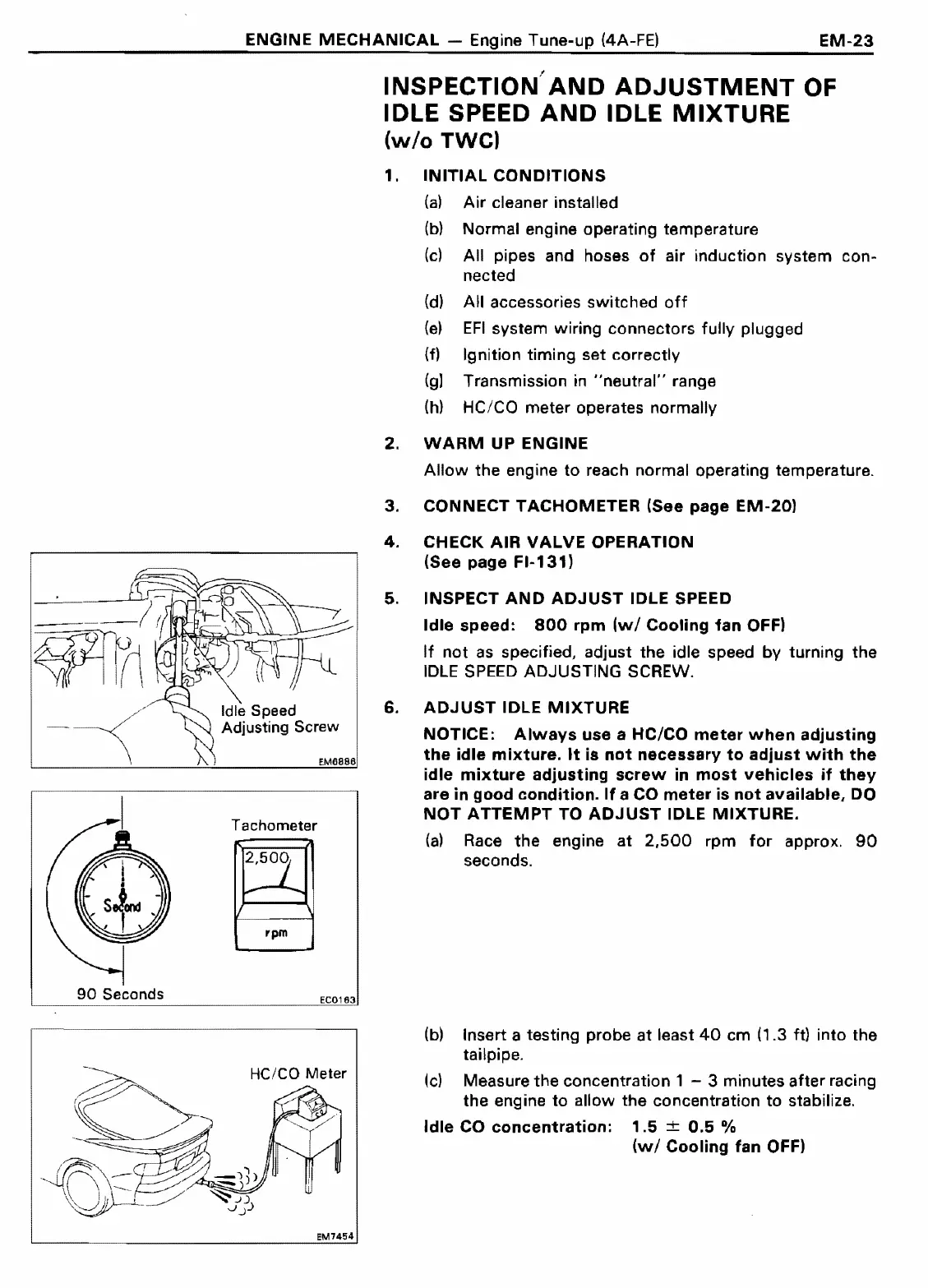

90

Seconds

ENGINE

MECHANICAL

- Engine Tune-up (4A-FE)

EM-23

Tachometer

rpm

EC0163

HC/CO

Meter

EM7454

INSPECTION'

AND

ADJUSTMENT

OF

IDLE SPEED

AND

IDLE

MIXTURE

(w/o

TWC)

1.

INITIAL

CONDITIONS

(a)

Air

cleaner installed

(b}

Normal engine operating temperature

(c)

All pipes and hoses

of

air induction

system con-

nected

{d)

All accessories switched

off

{e)

EFI

system wiring connectors

fully

plugged

{f)

Ignition timing set correctly

(g]

Transmission

in

"neutral"

range

(h}

HC/CO meter operates normally

2.

WARM

UP ENGINE

Allow

the

engine

to

reach normal operating temperature.

3.

CONNECT

TACHOMETER

(See

page

EM-20)

4.

CHECK

AIR

VALVE

OPERATION

(See page

Fl-131)

5. INSPECT

AND

ADJUST

IDLE SPEED

6.

Idle

speed:

800

rpm

(w/

Cooling

fan

OFF)

If

not

as

specified, adjust the idle speed

by

turning the

IDLE

SPEED

ADJUSTING

SCREW.

ADJUST

IDLE

MIXTURE

NOTICE:

Always

use

a HC/CO

meter

when

adjusting

the

idle

mixture.

It

is

not

necessary

to

adjust

with

the

idle

mixture

adjusting

screw

in

most

vehicles

if

they

are

in

good

condition.

If

a CO

meter

is

not

available#

DO

NOT

ATTEMPT

TO

ADJUST

IDLE

MIXTURE.

(a)

Race

the

engine

at

2,500

rpm

for

approx.

90

seconds.

(b)

Insert a testing probe

at

least

40

cm (1.3 ft} into the

tailpipe.

(c) Measure the concentration 1 - 3 minutes after racing

the engine to allow

the

concentration to stabilize.

Idle

CO

concentration:

1.5

±

0.5

%

(w/

Cooling

fan

OFF)

Loading...

Loading...