6 18-GE04D2-11

Installer’s Guide

e. It is always recommended that an auxiliary drain

pan be installed under a horizontal air handler

(See Condensate Piping) to prevent possible dam-

age to ceilings.

f. Isolate the auxiliary drain pan from the unit or

from the structure.

g. Connect the auxiliary drain line to a separate

drain line (no trap is needed in this line) and ter-

minate according to national and local codes.

h. If a return duct is connected to the air handler, it

must be the same dimensions as the return

opening shown in the outline drawing on page

13.

i.

On units with sheetmetal returns: Return

plenum should be flanged. Sheetmetal screws

must be 1/2" in length or shorter.

j. No sheetmetal screws may be used to attach

return ductwork on the side of the unit.

k. Openings where field wiring enters the

cabinet must be completely sealed.

Location of power entry is shown on the outline

drawing. Use 2.5" clear stickers provided to seal

all unused electrical knockouts. See Figure 8.

l. After ductwork connections are made, seal air-

tight and per Local codes.

HORIZONTAL RIGHT

a. For maximum efficiency and Customer ease of

filter maintenance, it is recommended that a

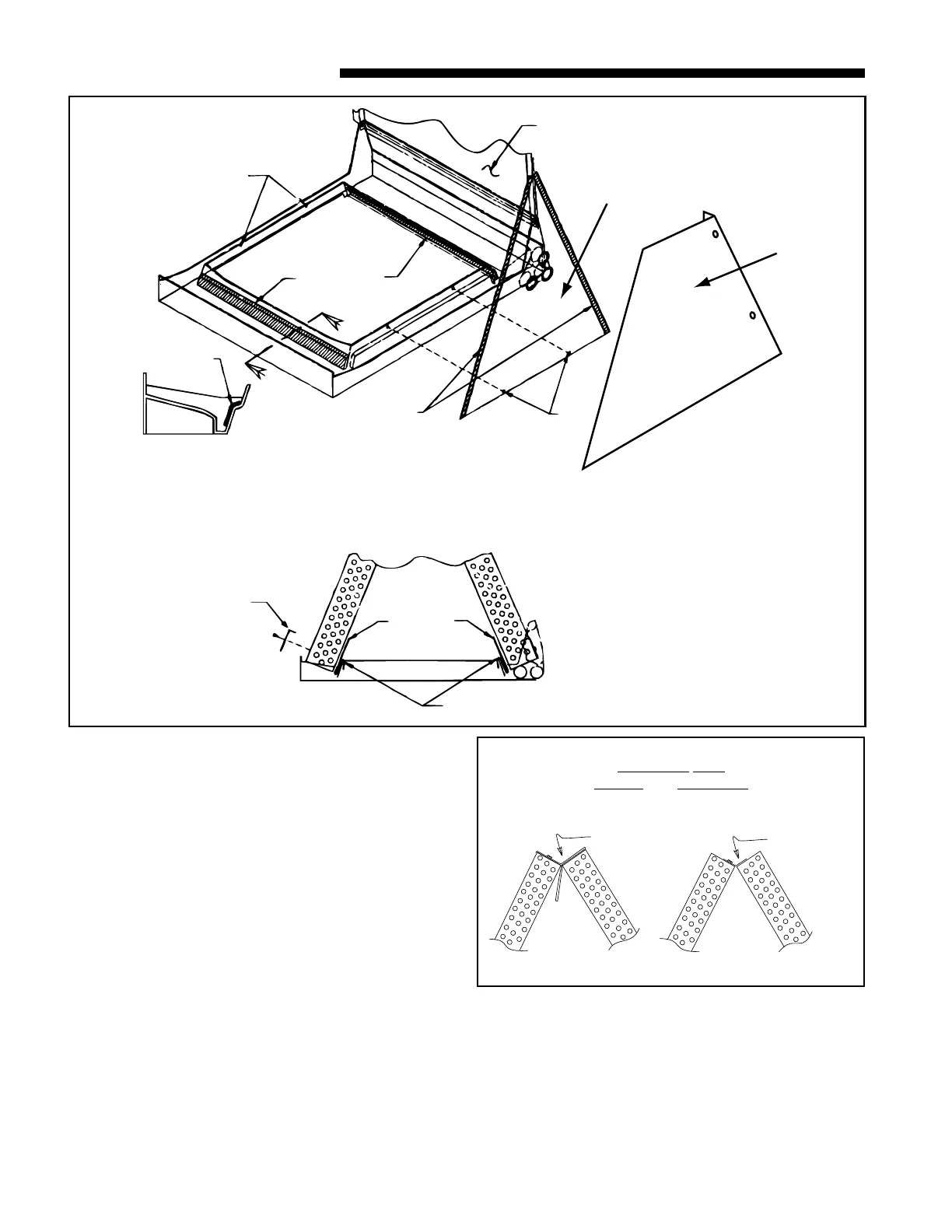

Remove

and

Discard

Replac

with

Narrow

Baffle

For Maximum Efficiency on

Horizontal Left,

Upflow and Downflow

Figure 10

X

X

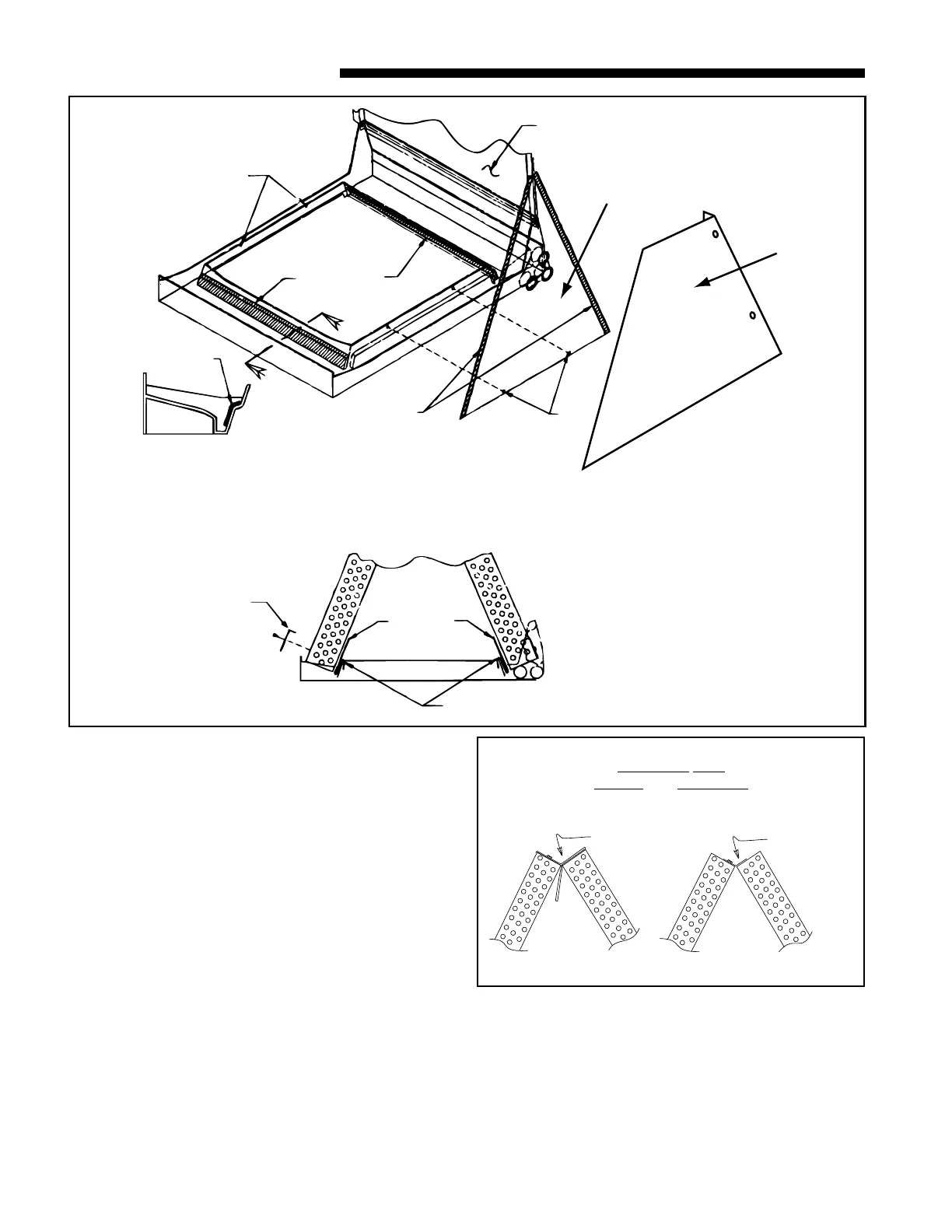

7/8" GASKET

SCREWS TO

REMOVE COIL

SCREWS TO

REMOVE COIL

DISCARD

DRIP TRAY

1/2" GASKET

INSIDE SURFACE

OF BAFFLE

/8" GASKET

SECT. X-X

TYP. BOTH SIDES)

WATER

BLOW-OFF

BAFFLES

ATTACH WITH

2 SCREWS

EACH SIDE

WATER

DIVERTER

BAFFLES

(5-ton only)

TRIANGULAR

BAFFLE

FRON

SHIEL

DOWNFLOW BAFFLE KIT

Figure 9

Loading...

Loading...