2 18-AD43D1-1C-EN

Installer’s Guide

This coil is pressurized with 8-12 psig of dry air. Do

not stand directly in front of the coil connections when

removing sealing plugs. If no pressure is released, check

for leaks.

C. RECOMMENDATION

If a coil is part of the total system installation, use the Installer’s

Guide packaged with the furnaces, outdoor sections, and

thermostat for physically installing those components.

E. FURNACE IN DOWNFLOW POSITION

D. FURNACE IN UPFLOW POSITION

APPLICATION USES UPFLOW COIL MODEL ONLY

IMPORTANT:

If installing the coil in the horizontal position, you MUST

use the horizontal kit listed below for this coil model

number and follow the instructions in the installation

guide provided with the conversion kit.

Model Number Horizontal Kit No.

4PXCBU36BS3HAC

BAYCONV23B

4PXCBD36BS3HDC

4PXCDU60BS3HAC

BAYCONV30C

4PXCDD60BS3HDC

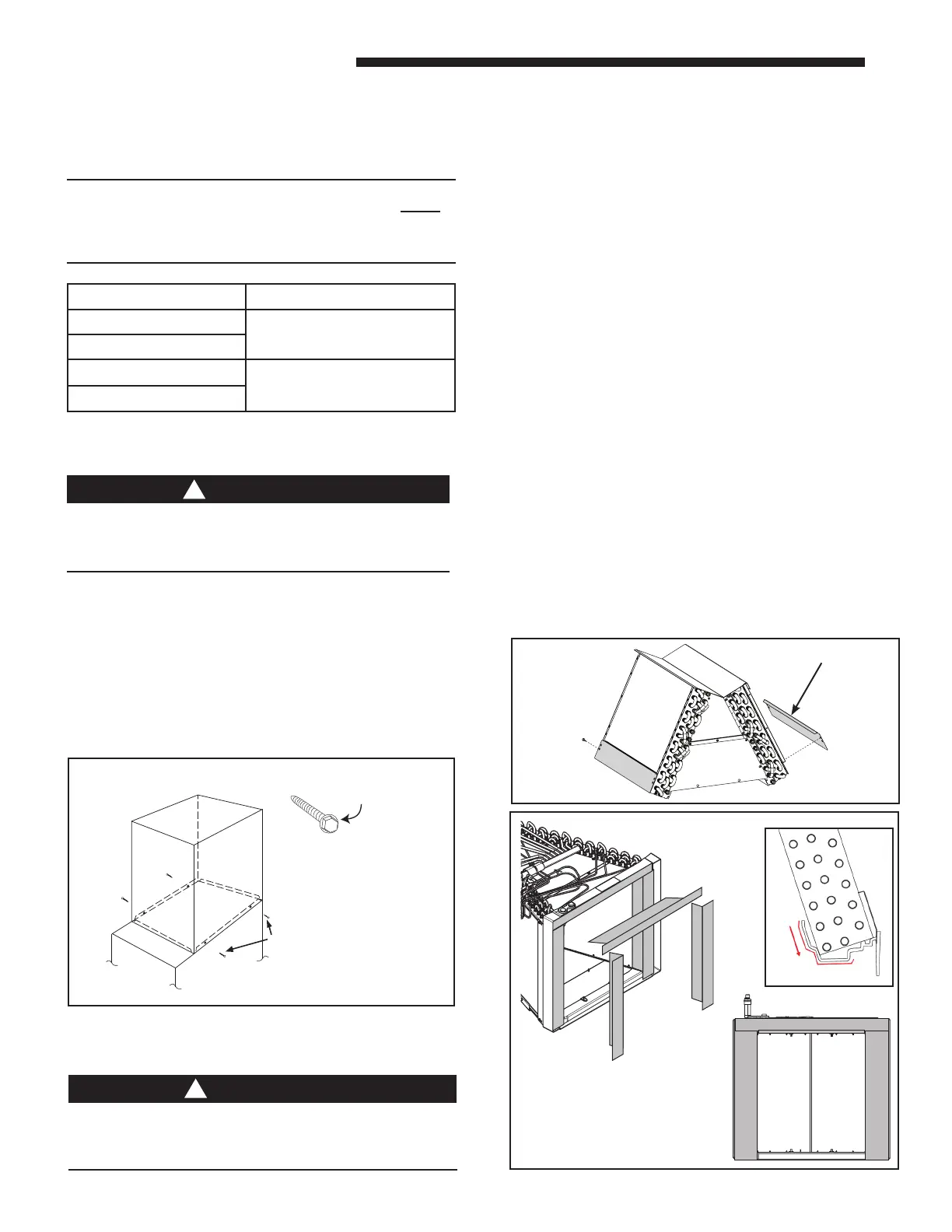

UPFLOW

FURNACE

CASED

COIL

SCREWS

(BO

1-1/2” MAXIMUM

FIELD SUPPLIED

FOR UPFLOW /

HORIZONTAL LEFT

INSTALLATIONS

Figure 2

Figure 4

Attach Downow

Bottom Gasket

Start

here

1. UPFLOW GAS FURNACE

a. Apply gasket material (duct seal eld supplied) to ALL

mating surfaces between the furnace and the coil case.

b. Set the coil case on top of the furnace. Connect the

ductwork to the coil case using eld supplied screws.

See Figure 2.

c. Secure the coil case to the furnace and seal for air

leaks as required.

This coil is pressurized with 8-12 psig of dry air. Do

not stand directly in front of the coil connections when

removing sealing plugs. If no pressure is released, check

for leaks.

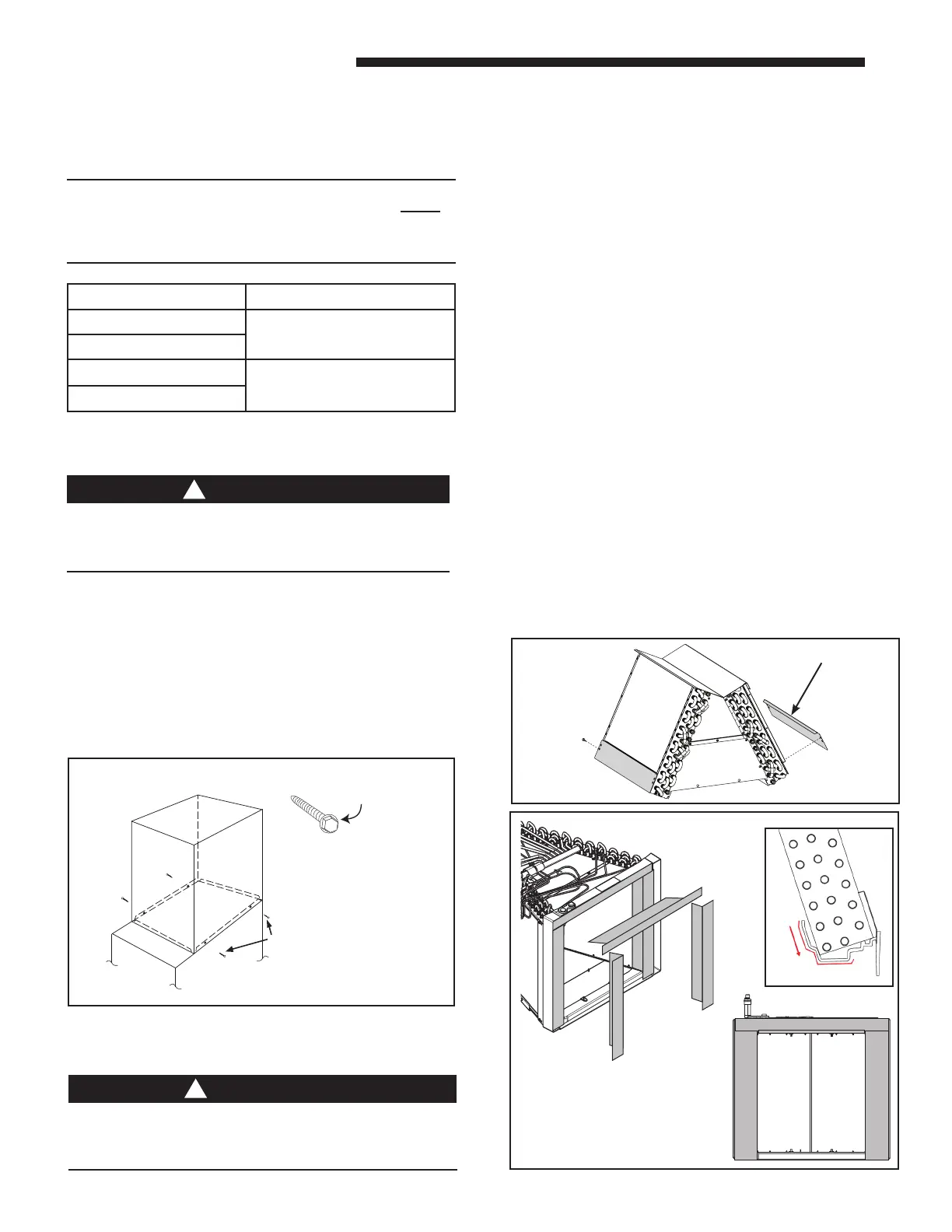

1. DOWNFLOW COIL CONVERSION

On 4PXCDD60BS and 4PXCDU60BS, installing the water

diverter baes is required for water management in downow

installations. Install the two outer water baes closest to the

drain pan using the provided 5/16" hex screws. See Figure 3.

2. DOWNFLOW GAS FURNACE

When a coil is used with a downow furnace, a subbase is not

required between the coil case and combustible ooring

a. Place the coil case on the furnace supply air plenum.

b. Secure the coil case to the plenum.

c. Set the furnace on top of the coil case, making sure that the

back side of the discharge opening is snug up against the

duct ange at the top rear of the coil case.

d. Secure the coil case to the furnace and seal for air

leaks as required.

3. DOWNFLOW GASKET INSTALLATION (OPTIONAL):

For unusually humid applications that expect prolonged operation

above 70% RH, it is recommended to use the BAYGSKT001A0

gasket kit to prevent water from forming on the bottom of the drain

pan and dripping into the supply ductwork.

a. Lay the coil on its back side.

b. Locate the 4" wide gasket material found in BAYGSKT001A0.

c. Attach the 4" gasket material to three sides of the bottom of

the drain pan as shown. Make sure to start by matching up

the edge of the gasket material to the inner edge of the drain

pan by the coil ns and working outwards.

d. The gasket material can be cut or ripped easily so that it can

be tailored to t. The gasket material must cover the three

sides along the entire length of the coil as shown in Figure 4.

WATER DIVERTER (X2)

Figure 3

Loading...

Loading...