CVHE-SVN02D-EN

12

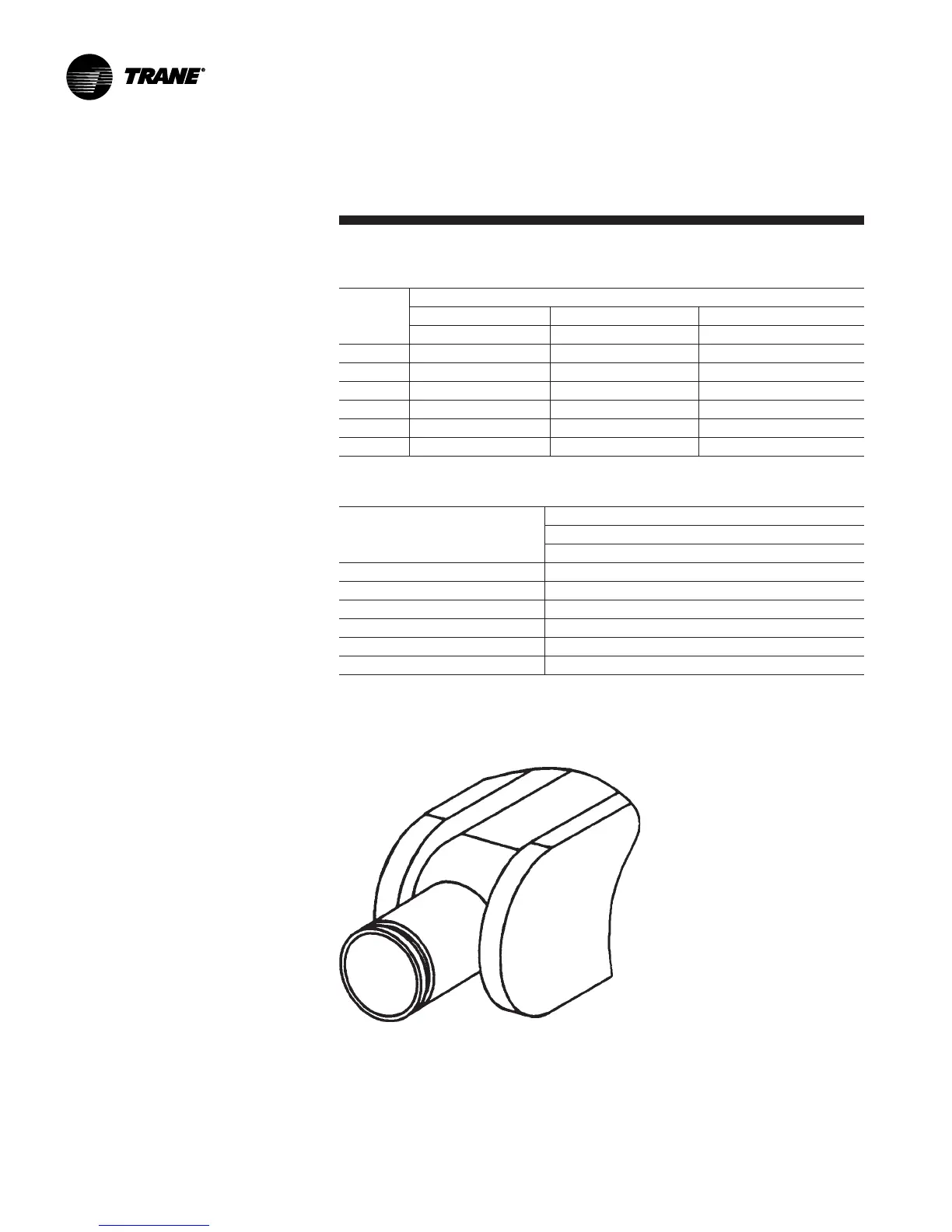

Water Piping

Table 1. Evaporator water piping connection sizes

Nominal Pipe Size (inch/mm)

1 Pass 2 Pass 3 Pass

EVSZ Inch mm Inch mm Inch mm

032 8 219.1 6 168.3 5 141.3

050 10 273.0 8 219.1 6 168.3

080 12 323.4 10 273.0 8 219.1

142 16 406.4 12 323.9 10 273.0

210 16 406.4 14 355.6 12 323.9

250 16 406.4 14 355.6 12 323.9

Note: EVSZ = Evaporator Shell Size; S = Short Shell, L = Long Shell, E = Extended Shell

Table 2. Condenser water piping connection sizes

Nominal Pipe Size (inch/mm)

2 Pass

CDSZ Inch mm

032 6 168.3

050 8 219.1

080 10 273.0

142 12 323.9

210 14 355.6

250 14 355.6

Note: CDSZ =Condenser Shell Size; S = Short Shell, L = Long Shell, E = Extended Shell

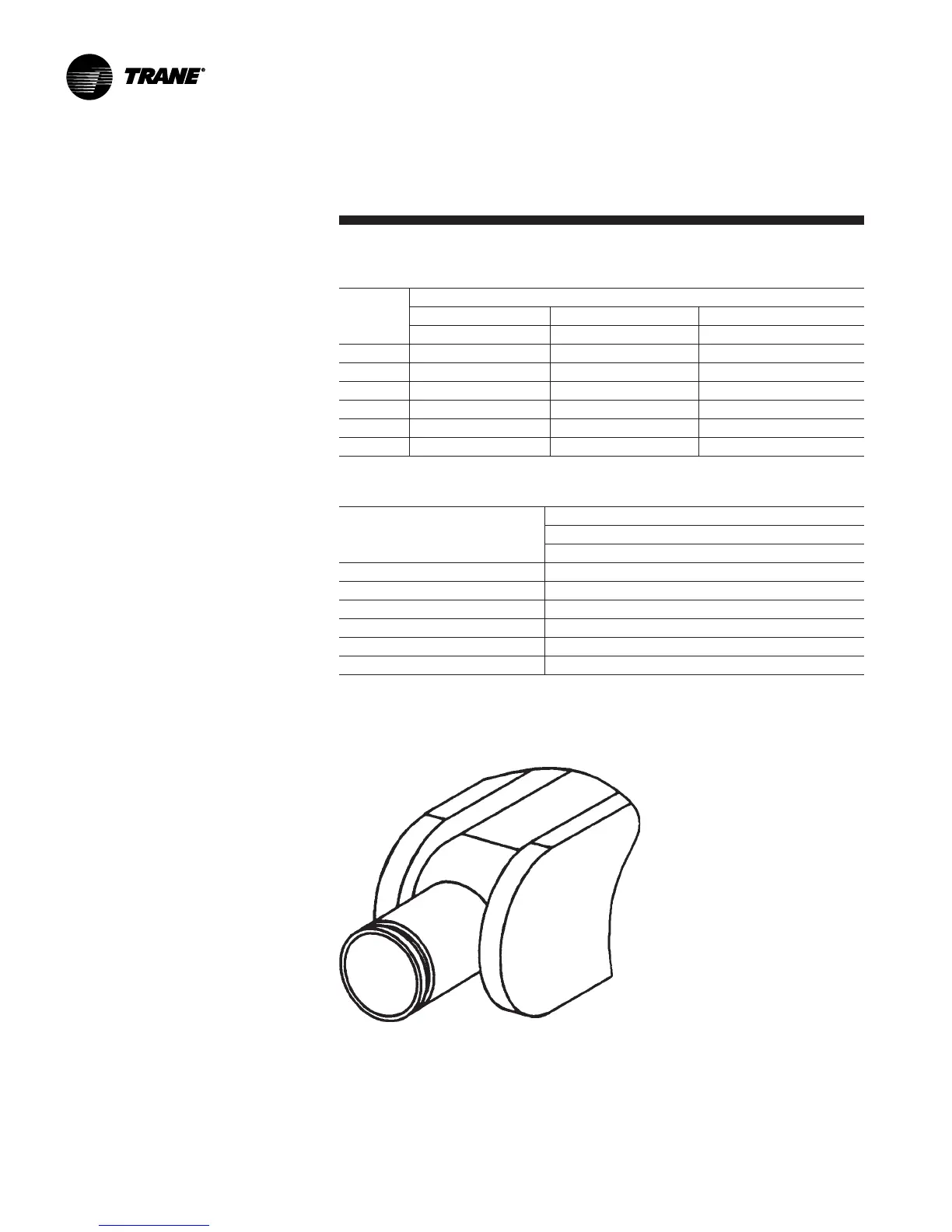

Figure 5. Typical CVHE grooved pipe connection

Water Piping Connections

For CVHEs beginning with design

sequence “1D,” all units (except

those with 032 through 050

condenser shells with 150 psig [1035

kPa] non-marine water boxes) use

cut-groove end NSP Victaulic style

pipe connections. All CVHGs

beginning with “1A” and later

design sequences. All CVHF units,

“A” and later design sequences, use

grooved-pipe connections. See

Figure 5.

Piping joined using grooved type

couplings, like all types of piping

systems, requires proper support to

carry the weight of pipes and

equipment. The support methods

used must eliminate undue stresses

on joints, piping and other

components; allow movement

where required, and provide for any

other special requirements (i.e.,

drainage, etc.).

Loading...

Loading...