RTAD-SVX01F-E4 79

Maintenance Procedures

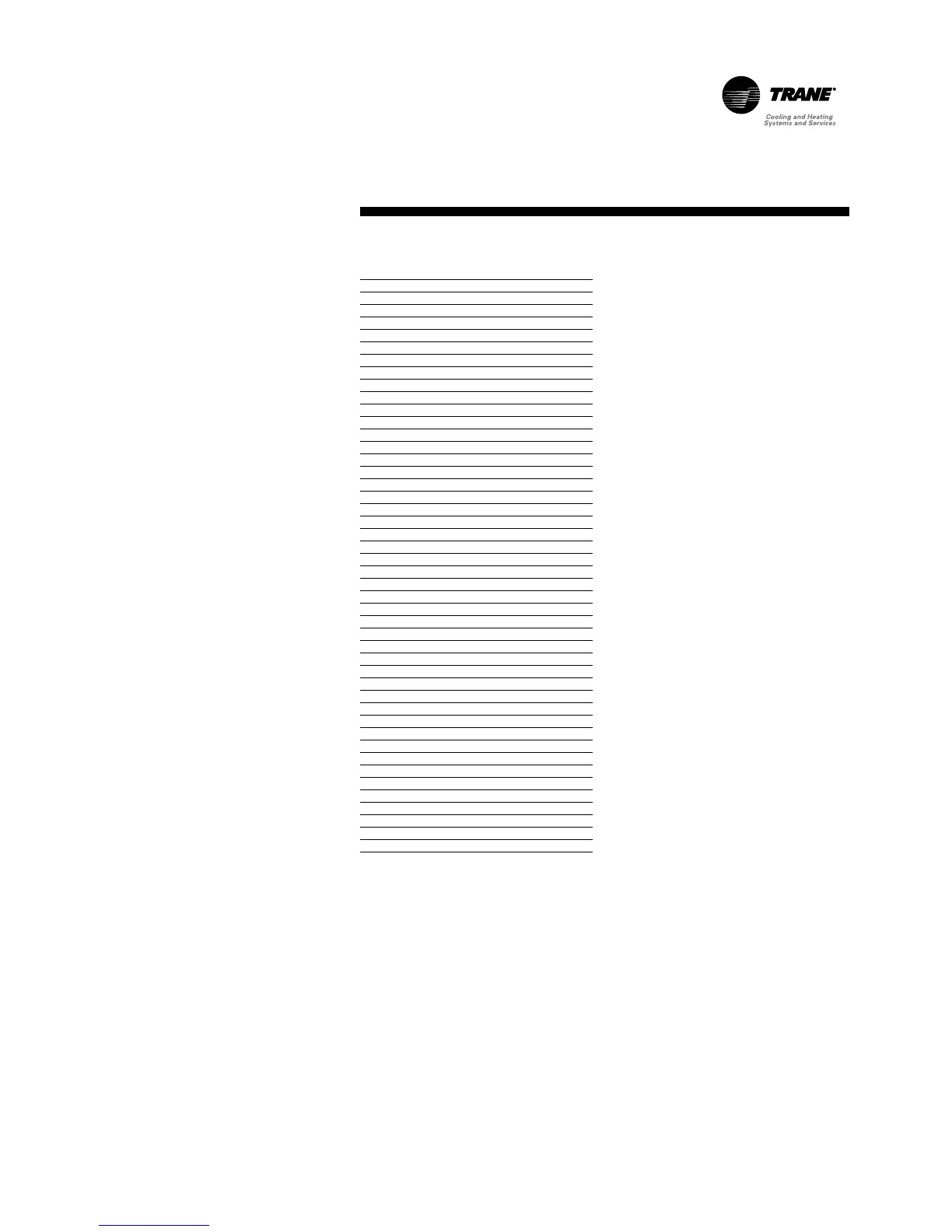

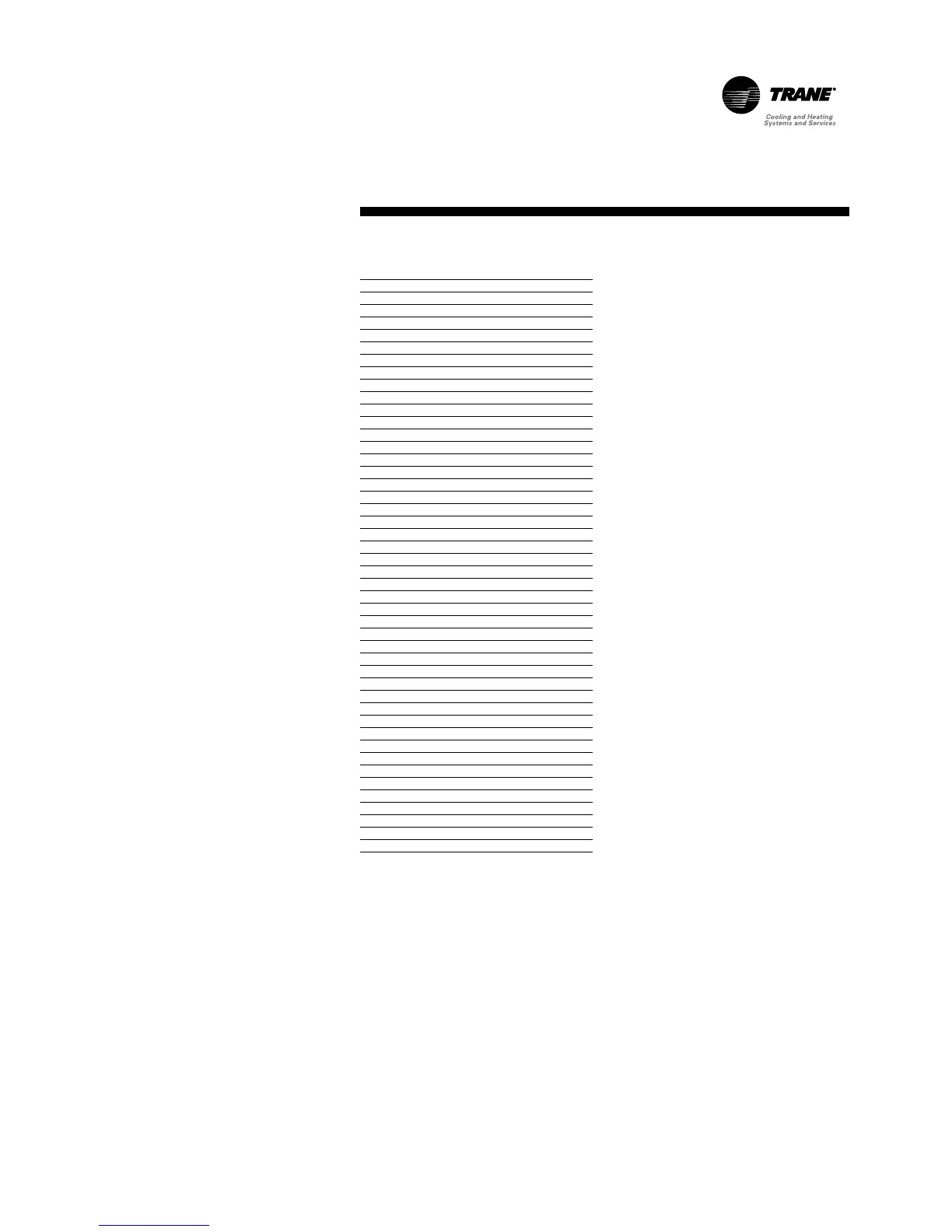

Table 40 - Refrigerant Charge

per Circuit (kg).

Unit Size Circuit A Circuit B

Standard

Free Cooling

RTAD 085 24 24

RTAD 100 30 32

RTAD 115 35 36

RTAD 125 36 37

RTAD 145 44 48

RTAD 150 44 48

RTAD 165 61 59

RTAD 180 61 61

RTAD 085 HE 32 34

RTAD 100 HE 35 36

RTAD 115 HE 42 45

RTAD 125 HE 42 45

RTAD 145 HE 59 61

RTAD 150 HE 59 61

Partial Heat Recovery

RTAD 085 26 26

RTAD 100 33 35

RTAD 115 38 39

RTAD 125 39 40

RTAD 145 47 51

RTAD 150 47 51

RTAD 165 65 63

RTAD 180 65 65

RTAD 085 HE 35 37

RTAD 100 HE 38 39

RTAD 115 HE 45 48

RTAD 125 HE 45 48

RTAD 145 HE 63 65

RTAD 150 HE 63 65

Total Heat Recovery

RTAD 100 55 52

RTAD 115 67 64

RTAD 125 68 64

RTAD 145 86 84

RTAD 150 86 84

RTAD 165 100 95

RTAD 180 100 98

RTAD 085 HE 63 60

RTAD 100 HE 65 62

RTAD 115 HE 86 84

RTAD 125 HE 86 84

RTAD 145 HE 97 95

RTAD 150 HE 97 95

Note: Size 085 does not exist for Total Heat Recovery

option but HE version is available

Refrigerant Filter Changing

Procedure

A dirty filter is indicated by a

temperature gradient across the

filter, corresponding to a pressure

drop. If the temperature downstream

of the filter is 4.4°C (8°F) lower than

the upstream temperature, the filter

should be replaced. A temperature

drop can also indicate that the unit is

undercharged. Ensure proper

subcooling before taking

temperature readings.

1 With the unit off, verify that the

EXV is closed. Close liquid line

isolation valve. On units with

remote evaporators or oil cooling

circuits, close ball valve on oil

cooler liquid line.

2 Attach vacuum hose to service

port on liquid line filter flange.

3 Evacuate refrigerant from liquid

line and store.

4 Remove vacuum hose.

5 Depress schrader valve to

equalize pressure in liquid line

with atmospheric pressure.

6 Remove bolts that retain filter

flange.

7 Remove old filter element.

8 Inspect replacement filter element

and lubricate o-ring with Trane

OIL00048.

Note: do not use mineral oil. It will

contaminate the system.

9 Install new filter element in filter

housing.

10 Inspect flange gasket and replace

if damaged.

11 Install flange and torque bolts to

19-22 mN (14-16 lb-ft).

12 Attach vacuum hose and

evacuate liquid line.

13 Remove vacuum hose from liquid

line and attach charging hose.

14 Replace stored charge in liquid

line.

15 Remove charging hose.

16 Open liquid line isolation valve.

On units with remote evaporators

or oil cooler circuits, open oil

cooler liquid line ball valve.

Adding Refrigerant

If the entire charge has been

removed, perform the following

procedures to recharge the unit.

1 Open all service valves

2 Establish water flow through the

evaporator. Connect a hose from

the refrigerant bottle to the

backseat port on the liquid line

shutoff valve. Midseat the valve.

CAUTION! The evaporator water

flow needs to be established and

maintained while adjusting the

charge to avoid freezing and

rupturing the tubes.

3 It may not be possible to put the

entire amount of refrigerant charge

required using step 2. If so, start

the unit and add liquid refrigerant

through the liquid line service

valve.

4 Once the unit has been charged

with refrigerant, start the unit.

Measure the subcooling and verify

that the refrigerant charge is

correct.

Loading...

Loading...