18-CD33D1-4 29

Installer’s Guide

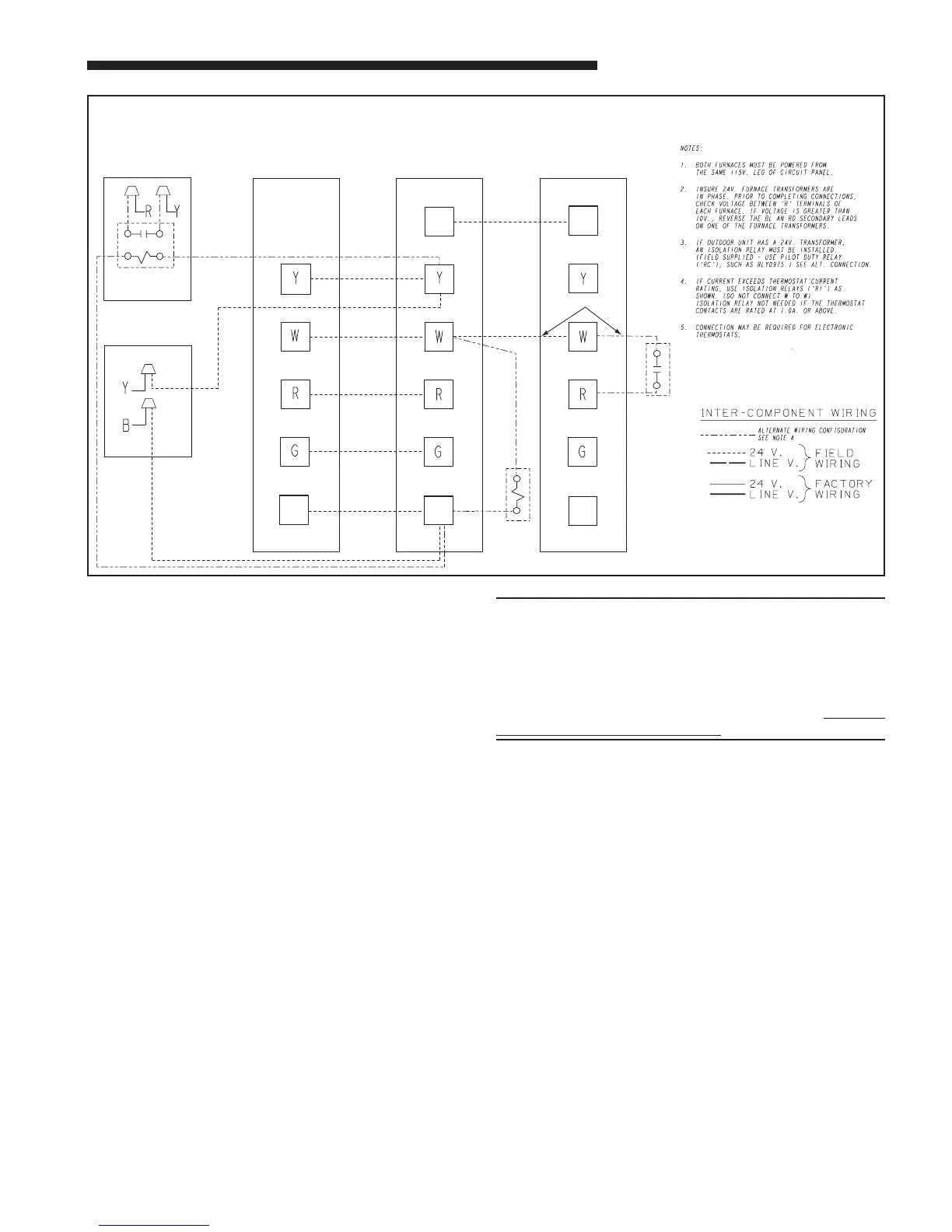

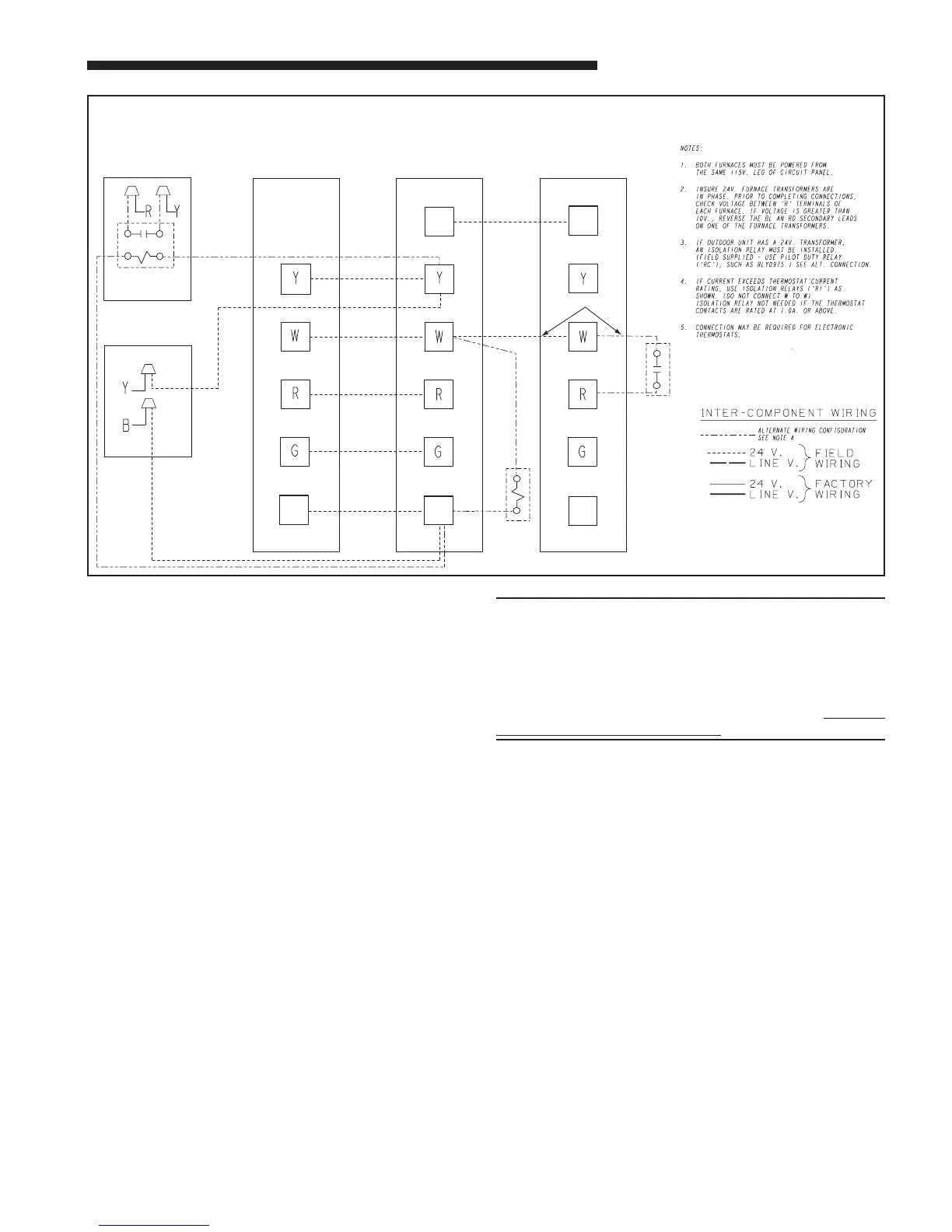

TWIN

TWIN

R1

R1

TWINNING CONNECTION DIAGRAM

FOR TWINNING 1 STAGE FURNACES WITH

SINGLE WIRE TWINNING FEATURE

1 STAGE HEAT / 1 STAGE COOL THERMOSTAT

1 STAGE

HEATING / COOLING

THERMOSTAT FURNACE NO. 1

FURNACE NO. 2

BLOWER OPERATION OF

UNIT NO. 2 IS SYNCRONIZED

WITH UNIT NO. 1 VIA SIGNALS

FROM TWIN CONNECTION.

SEE NOTE 4

SEE NOTE 5

ISOLATION RELAY

(FIELD SUPPLIED)

SEE NOTE 4

ISOLATION RELAY

SEE NOTE 4

OUTDOOR UNIT

(NO TRANSFORMER)

OUTDOOR UNIT

(WITH TRANSFORMER)

RC

ISOLATION RELAY

(FIELD SUPPLIED)

SEE NOTE 3

B/C

B/C

B/C

From Dwg. 21B341423 Rev. 2

NOTE:

Maximum pressure to the gas valve for natural gas is

13.8" W.C. Minimum pressure is 5.0" W.C. Maximum

pressure to the gas valve for propane is 13.8" W.C.

Minimum pressure is 11.0" W.C.

All gas fittings must be checked for leaks using a

soapy solution before lighting the furnace. DO NOT

CHECK WITH AN OPEN FLAME!

ANSI Z223.1/ NFPA 54 or National Standard of Canada,

Natural Gas and Propane Installation Code, CSA B149.1.

The upflow/ horizontal furnace is shipped standard for

left side installation of gas piping. A knockout is provided

on the right side for an alternate gas piping arrangement.

See Figure 37.

The installation of piping shall be in accordance with pip-

ing codes and the regulations of the local gas company.

Pipe joint compound must be resistant to the chemical re-

action with liquefied petroleum gases.

Refer to piping Table 10, for delivery sizes. Connect gas

supply to the unit, using a ground joint union and a manu-

al shut-off valve as shown in Figures 37-39.

National codes require a condensation drip leg to be in-

stalled ahead of the controls as shown in Figures 37-39.

The furnace and its individual shut-off valve must be dis-

connected from the gas supply piping system during any

pressure testing of that system at test pressures in ex-

cess of 1/2 psig (3.5 kPa).

The furnace must be isolated from the gas supply piping

by closing its individual manual shut-off valve during any

pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.5 kPa).

GAS PIPING

Loading...

Loading...