32 18-CD29D1-11

Installer’s Guide

TABLE 15

4. Read the “Flow” column opposite the number of sec-

onds clocked.

5. Use the following factors if necessary:

For 1 Cu. Ft. Dial Gas Flow CFH =

Chart Flow Reading ÷2

For 1/2 Cu Ft. Dial Gas Flow CFH =

Chart Flow Reading ÷4

For 5 Cu. Ft. Dial Gas Flow CFH =

10X Chart Flow Reading ÷4

6. Multiply the final figure by the heating value of the

gas obtained from the utility company and compare

to the nameplate rating. This must not exceed the

nameplate rating.

Gas Valve Adjustment

Changes can be made by adjusting the manifold pressure

(See Table 17, or changing orifices (orifice change

may not always be required). To adjust the manifold

pressure:

1. Turn off all electrical power to the system.

2. Attach a manifold pressure gauge with flexible tub-

ing to the outlet pressure boss marked “OUT P” on

White-Rodgers gas valve model 36G or 36J. See Fig-

ure 58 for White-Rodgers gas valve model 36J. See

Figure 57 for White-Rodgers gas valve model 36G.

3. Loosen (Do Not remove) the pressure tap test set

screw one turn with 3/32" hex wrench.

a. The pressure tap adjustment kit (KIT07611) con-

tains a 3/32" hex wrench, a 5/16" hose and a con-

nector and can be ordered through Global Parts.

4. Turn on system power and energize valve.

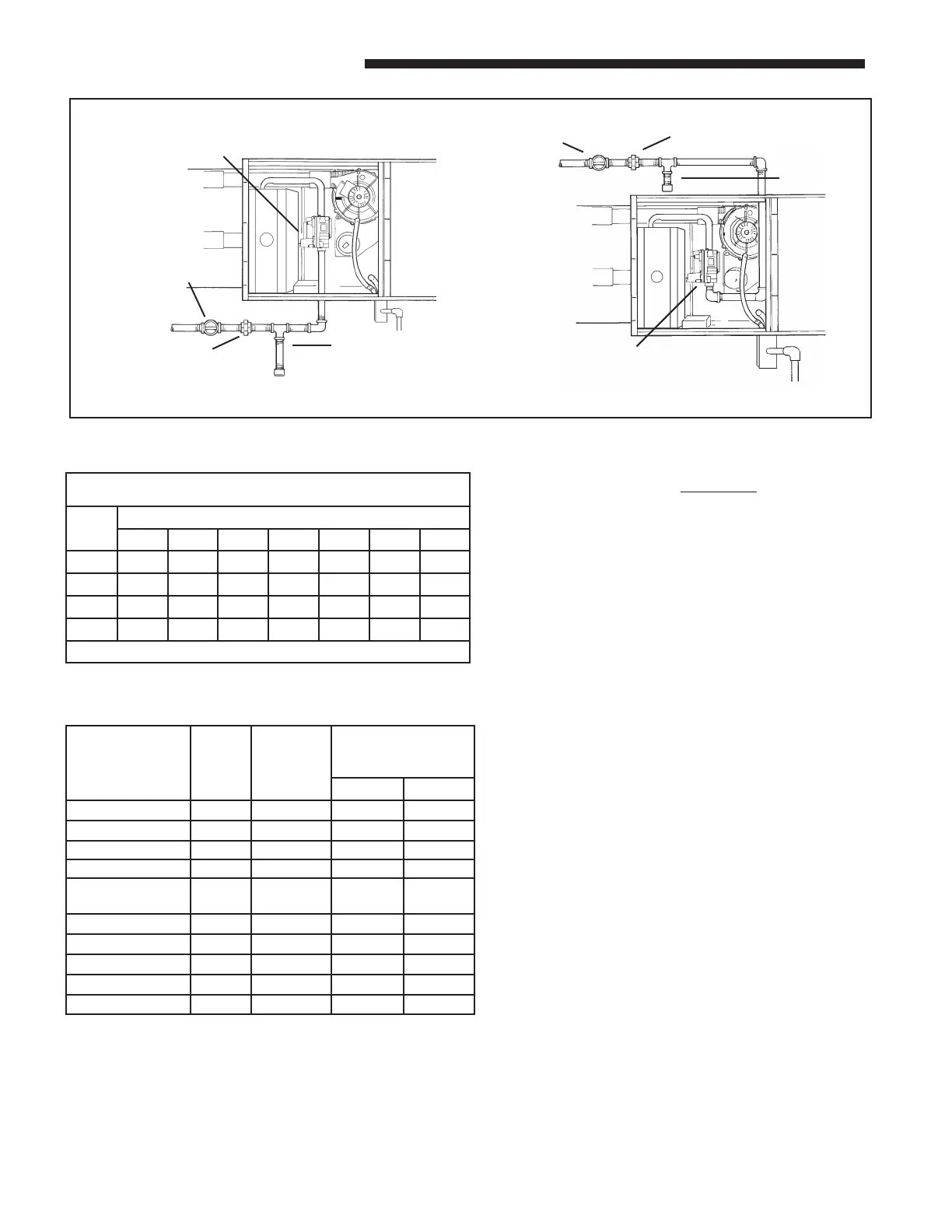

HORIZONTAL FURNACE GAS PIPING MAY BE FROM EITHER SIDE (UPFLOW SHOWN)

GROUND UNION JOINT

DRIP

LEG

AUTOMATIC GAS VALVE WITH

MANUAL SHUTOFF

MAIN MANUAL

SHUTOFF VALVE

GROUND

UNION JOINT

DRIP

LEG

MAIN MANUAL

SHUTOFF VALVE

AUTOMATIC GAS VALVE

WITH MANUAL SHUTOFF

R

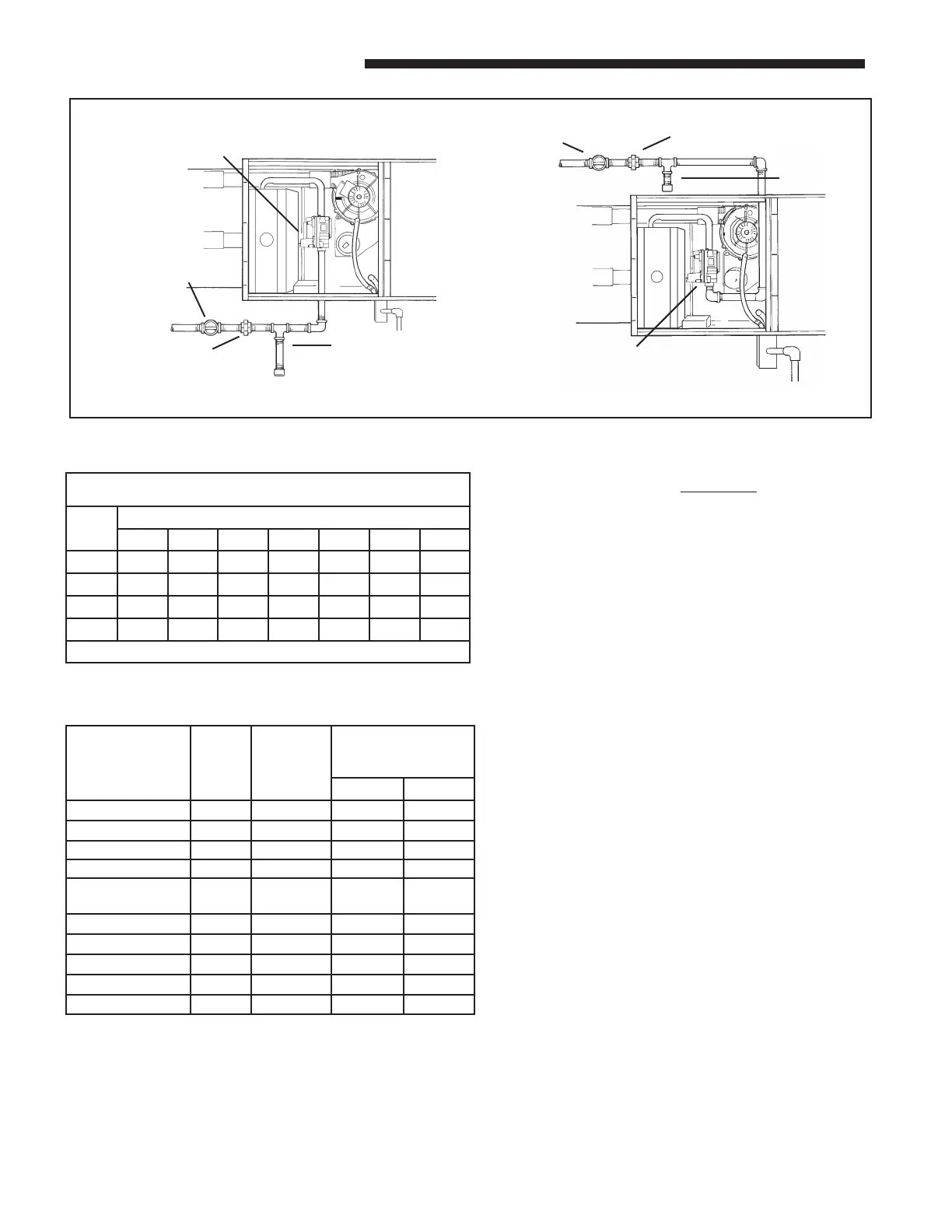

ORIFICE SIZES

MODEL

INPUT

RATING

BTUH

NUMBER

OF

BURNERS

MAIN BURNER

ORIFICE

DRILL SIZE

NAT. GAS LP GAS

*UH1B040A9241A 40,000 2 45 56

*UH1B060A9361A 60,000 3 45 56

*UH1B080A9421B 77,000 4 45 56

*UH1C080A9601A 80,000 4 45 56

*UH1C100A9481A

*UH1D100A9601A

100,000 5 45 56

*UH1D120A9601A 110,000 6 45 56

*DH1B040A9241A 40,000 2 45 56

*DH1B065A9421A 60,000 4 48 56

*DH1C085A9481A 80,000 5 48 56

*DH1D110A9601A 110,000 6 48 56

NATURAL GAS ONLY

TABLE OF CUBIC FEET PER HOUR OF GAS

FOR VARIOUS PIPE SIZES AND LENGTHS

PIPE

SIZE

LENGTH OF PIPE

10 20 30 40 50 60 70

1/2 132 92 73 63 56 50 46

3/4 278 190 152 130 115 105 96

1 520 350 285 245 215 195 180

1-1/4 1050 730 590 520 440 400 370

This table is based on pressure drop of 0.3 inch W.C. and 0.6 SP.GR. gas

TABLE 16

COMBUSTION AND INPUT CHECK

1. Make sure all gas appliances are off except the furnace.

2. Clock the gas meter with the furnace operating (deter-

mine the dial rating of the meter) for one revolution.

3. Match the “Sec” column in the gas flow (in cfh) Table 18

with the time clocked.

Loading...

Loading...