12 UHM-DHM-SF-1H

Service Facts

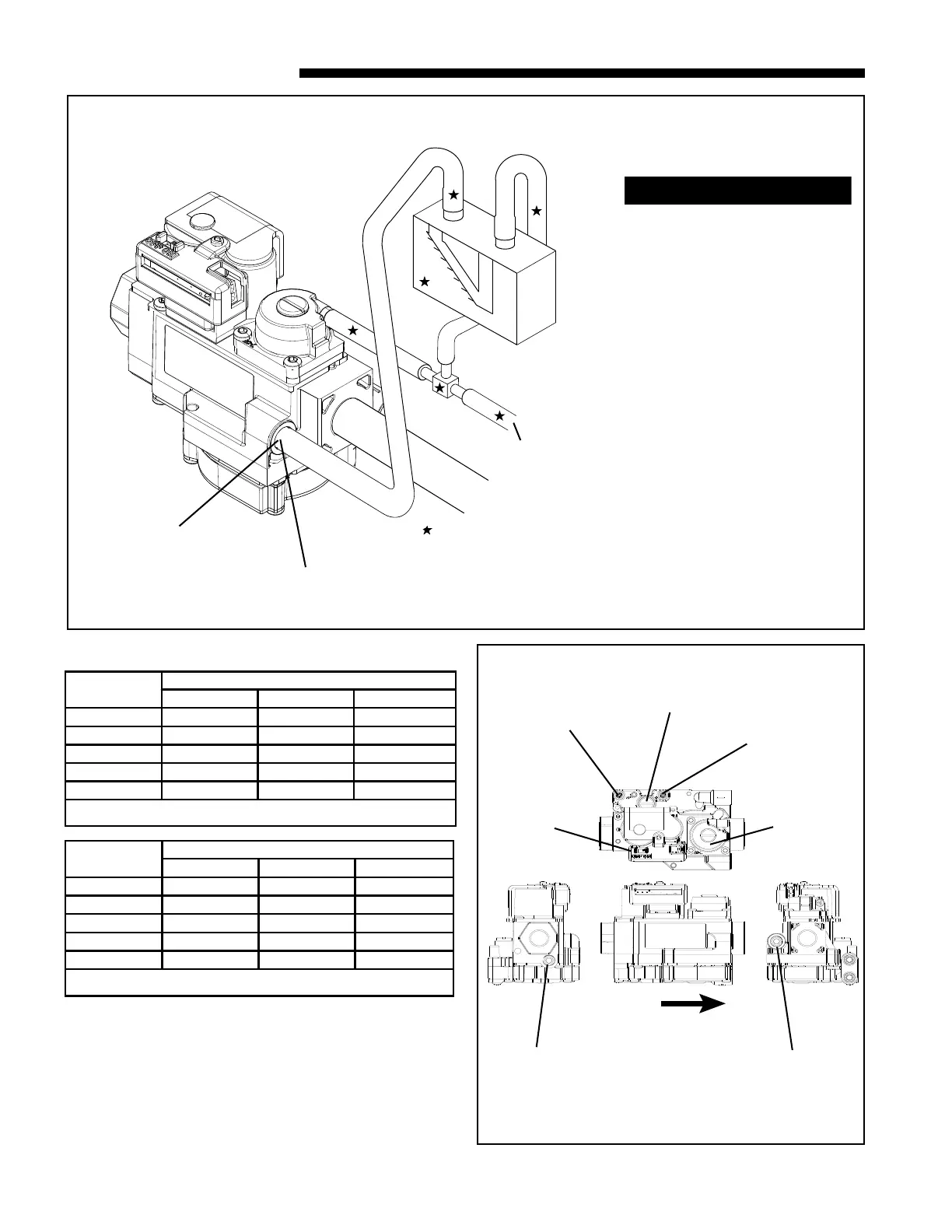

CORRECT METHOD OF CHECKING DIRECT VENT MANIFOLD PRESSURE

WITH BURNER BOX REFERENCED

Manifold

Pressure

Measurement

Fitting

Field Supplied

Connects to

Burner Box

Pressure Hose

A Field Supplied barb fitting must be used

on the gas valve to attach the hose

Gas Valve

On/ Off

Toggle

Switch

High Heat

Manifold

Pressure

(Adjustment

under cover)

Inlet Pressure

Measurement Fitting

7

Negative Control

Pressure Post

Positive Control

Pressure Post

Low Heat Manifold

Pressure

(Adjustment under

cover)

Manifold

Pressure

Measurement

Fitting

Flow

TABLE 1

Furnace Input rate

(KBTU/hr)

FINAL LP MANIFOLD PRESSURE SETTINGS (inches w.c

40% 65% 100%

60 2.1 ± 0.5 Not Adjustable 10.0 ± 0.5

80 2.1 ± 0.5 Not Adjustable 10.0 ± 0.5

100 2.1 ± 0.5 Not Adjustable 10.0 ± 0.5

Downflow 120 2.1 ± 0.5 Not Adjustable 10.0 ± 0.5

Upflow 120 2.9 ± 0.5 Not Adjustable 10.0 ± 0.5

For upflow 120KBTU/hr model, 1st stage is 45%

Manifold pressures apply for Propane applications ONLY

Furnace Input rate

(KBTU/hr)

FINAL NG MANIFOLD PRESSURE SETTINGS (inches w.c

40% 65% 100%

60 0.7 + 0.2 / - 0.0 Not Adjustable 3.5 ± 0.2

80 0.7 + 0.2 / - 0.0 Not Adjustable 3.5 ± 0.2

100 0.7 + 0.2 / - 0.0 Not Adjustable 3.5 ± 0.2

Downflow 120 0.7 + 0.2 / - 0.0 Not Adjustable 3.5 ± 0.2

Upflow 120 0.9 + 0.2 / - 0.0 Not Adjustable 3.5 ± 0.2

For upflow 120KBTU/hr model, 1st stage is 45%

Manifold pressures apply for Natural Gas applications ONLY

WARNING

!

EXPLOSION HAZARD

REPLACE AND/OR

TIGHTEN ALL PLUGS

REMOVED OR LOOS-

ENED WHEN ADJUST-

ING GAS PRESSURE.

LEAK CHECK THE FIT-

TINGS BEFORE PLAC-

ING INTO REGULAR

SERVICE. FAILURE TO

FOLLOW THIS WARNING

COULD RESULT IN SE-

RIOUS PERSONAL IN-

JURY, PROPERTY DAM-

AGE, OR DEATH

Slope

Gauge

6

Loading...

Loading...