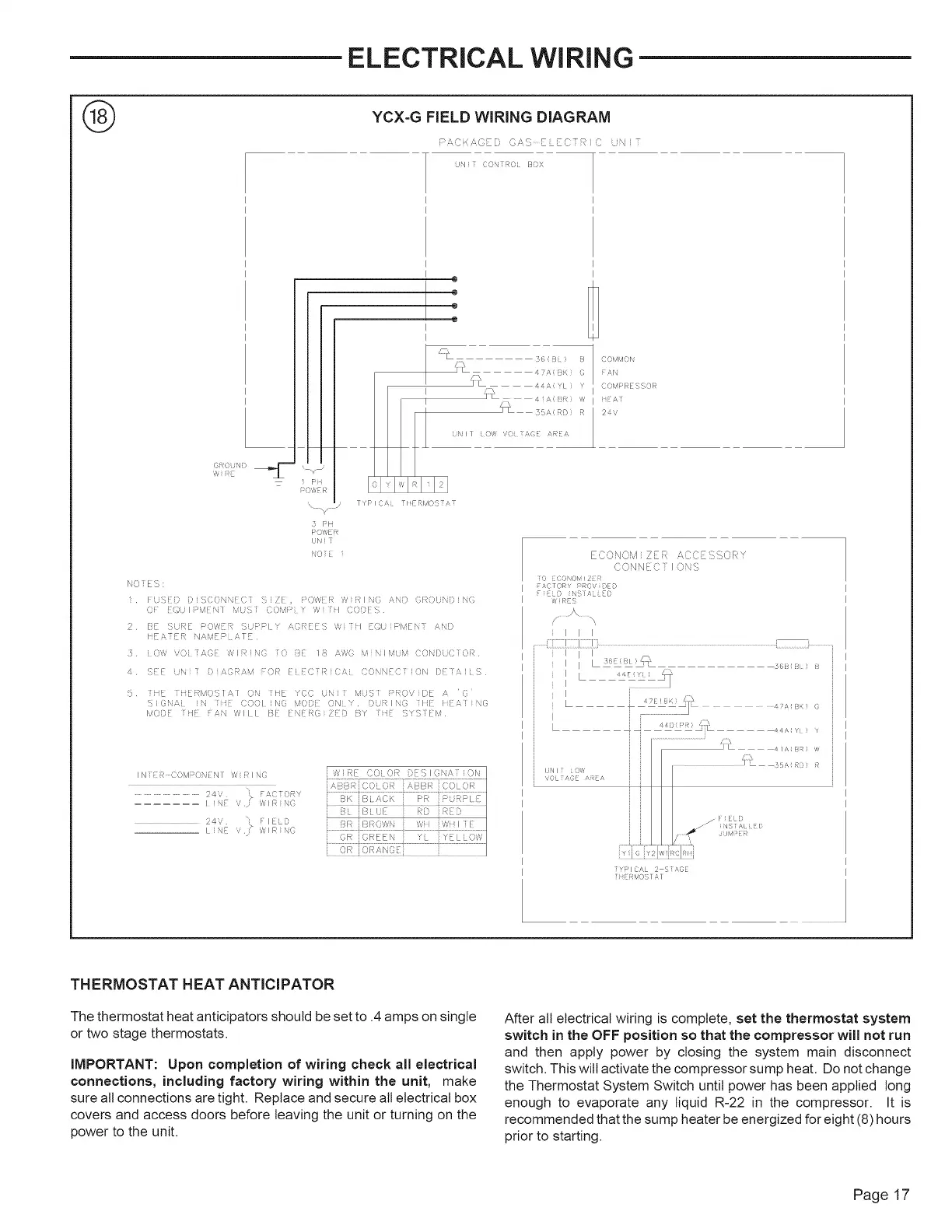

ELECTRICAL WIRING

®

YCX-G FIELD WiRiNG DIAGRAM

_;/xPKAGED ,0£S ELE( AIS L:IT

IN T CONT O[ BOX

GRO N)

F4

PO)i R

y

3 PH

P0',_7E F

UN JT

@

9,

I

I

L

36, B ) B

4 7A ( Bg: :, C

'!1 L_ 44 A ,: YL ) Y

'_ 4 1A ( _F_) W

35A(RD) R

LN I [ O,h VO ACE ,SRE/_

COMMON

FAN

COMPRESSOR

i_E!AI

24V

TYPICAL TI ERMOST/_T

NOIES:

, I UUII i) CONN (i JZI , P)WIR ¢/ R IN{ AND _IR)LNI) NO

OF EQUI %'(N/ !,,,'kS] COMP "/ W I CODES

2 BE SUrE POW _{ S_PPl Y ACRFES h T I UJFI',,/'EN AND

I EATkq NA",/ P[ AT

5 i OW vO ;AGF: WI:PiNG ]O BE 18 Ago b' NIb!U:_,4 CONDUC OR

4 S/E LN D AG:SA!v ::O1:5 Ei EC R (A CONNEC'i }N (E'A _ S

!_, HF HLRI,/OSIAI ON JHE YCC UN 'v'J F OVJDE A 'O

SJGNA N COOl JNG I'/ODJ ON Y. DU{IN] ill JlA NG

I,¢O[E J/ AN Will BE ENERG ZE) :/Y i; SYS]EI,, ,_

INTER COblPONENi \,'_iRINO

.................................... 24v FACTCRY

, £

liNE ,,j '&_IRiNG

24',,/ "k fflELD

liNE F ,'_IRiNC

,j

ECONC, M ZER ASCESSORY

C0 NNE{} I )

,':, CONOd/_

ACTOR" PROV DED

E D N_,iALLEE

¢,, RE'

J I I I

..........::::::::::::::::::::::::::::::::.............................................................................................................................................................i...............................................

I I I

I I L3C_zL L" 61{1!1} i

I i _ ,_,<, /\

J

44Zx YI Y

[NIT iOL'

"O F/',GE /_EA

ii:

iYPlCAL 9 SiAOE

I ERMOt I_1

THERMOSTAT HEAT ANTICIPATOR

The thermostat heat anticipators should be set to .4 amps on single

or two stage thermostats.

IMPORTANT: Upon completion of wiring check all electrical

connections, including factory wiring within the unit, make

sure all connections are tight. Replace and secure all electrical box

covers and access doors before leaving the unit or turning on the

power to the unit,

After all electrical wiring is complete, set the thermostat system

switch in the OFF position so that the compressor will not run

and then apply power by closing the system main disconnect

switch. This will activate the compressor sump heat. Do not change

the Thermostat System Switch until power has been applied long

enough to evaporate any liquid R-22 in the compressor. It is

recommended that the sump heater be energized for eight (8) hours

prior to starting.

Page 17

Loading...

Loading...