INSTALLER'S GUIDE

18-HH08D10-2 Page 5

SENSOR POSITIONING

AIRFLOW

DIMENSIONS

2 2

2 2

2

INSTALLATION:

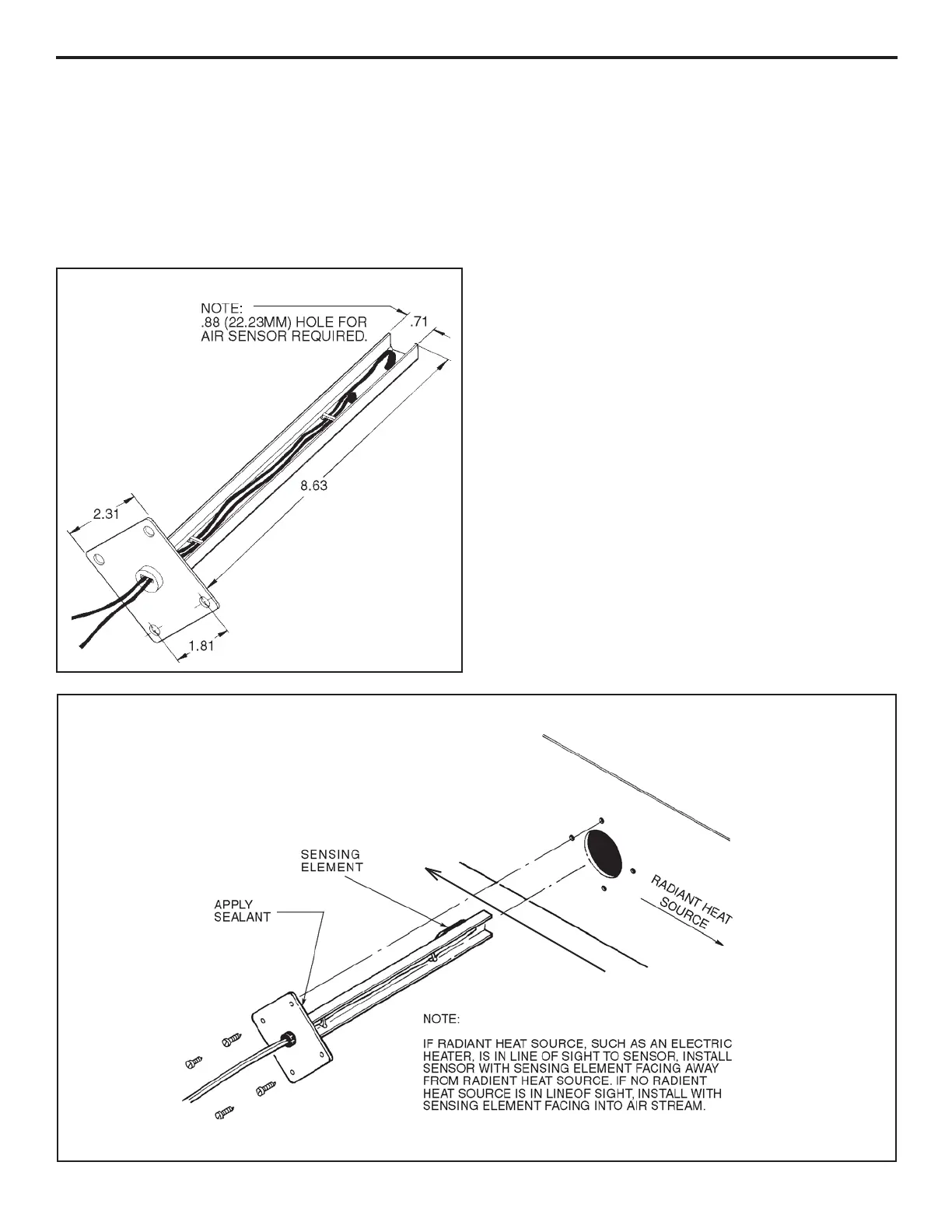

The Discharge Air Sensor is mounted in the discharge

(supply air) duct by cutting a

7/

8" diameter (22.225mm)

hole in the duct. A hole-saw, Greenlee punch or similar

tool can be used - see Figure 3.

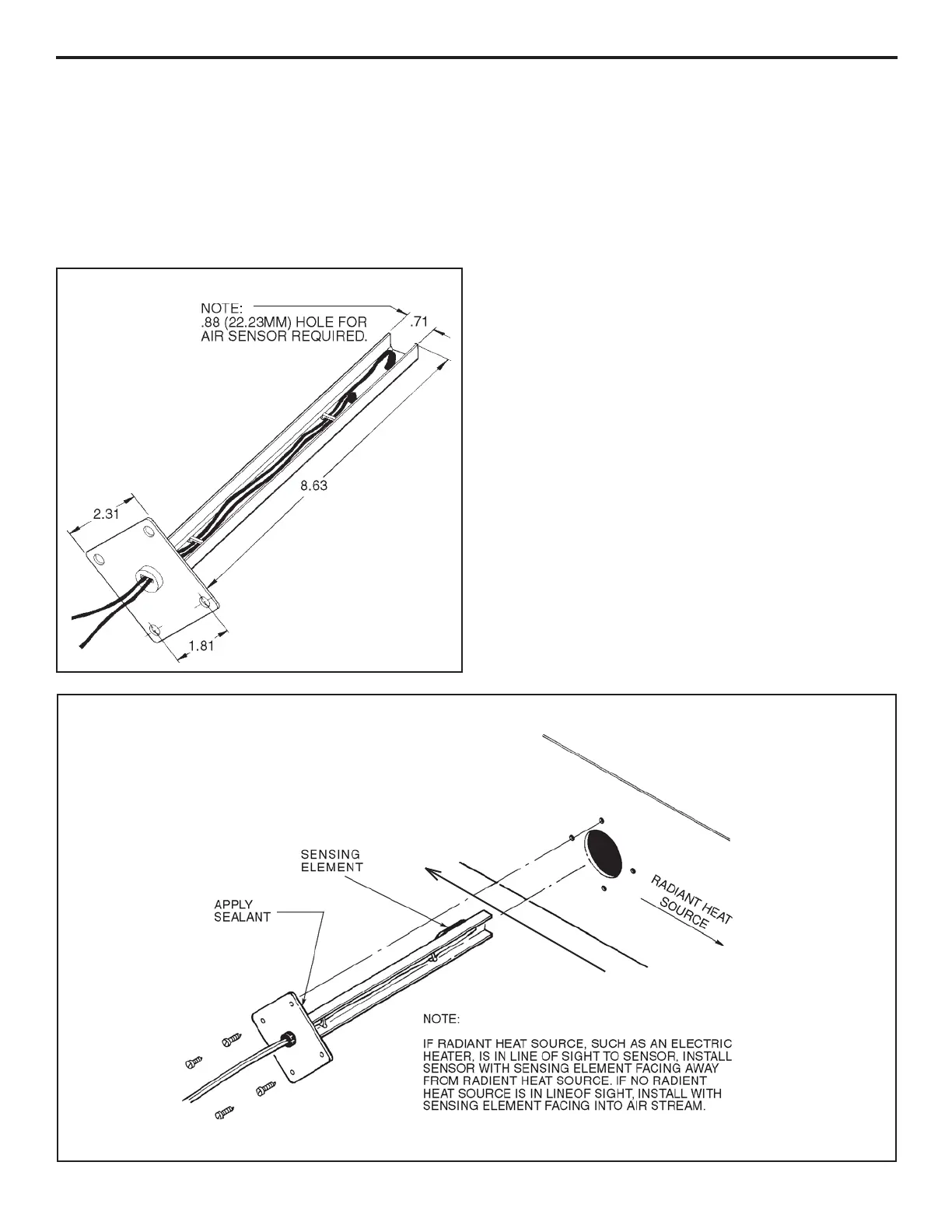

Note: Locate the Discharge Air Sensor in an area of the

discharge, (supply), air duct where laminar flow can be

expected. Avoid dead air areas where representative dis-

charge air temperatures may not exist.

The mounting plate can be used as a template to locate the

four screw holes. Before drilling the four holes, determine

the proper positioning of the sensor as follows: If a radiant

heat source such as an electric heater is in line of sight from

the sensor, position the sensor so that the black thermistor

sensor faces away from the radiant heat source. (This will

prevent a false reading due to the radiant effect on the

thermistor - see Figure 3.)

If no radiant heat source is in line of sight, position the

sensor with the sensing element facing into the air stream

(fastest response). When the proper positioning has been

determined, mark the location of the four holes and drill to

accept #8 sheet metal screws (not furnished).

Apply a circle of caulk sealer (or equivalent) to the duct side

of the sensor mounting plate before mounting to reduce air

leakage.

If a 4" x 4" (106mm x 106mm) electrical box is to be used,

refer to Figure 4. In this case, the caulk sealer is applied

to the duct side of the box as well as to the sensor mounting

plate.

An unobstructed depth of approximately 9" (228.6mm) in

the duct is required in order to accept the sensor probe,

which is approximately 8

3/

4" (222.25mm) in length.

3 3

3 3

3

Loading...

Loading...