Page 18 of 20

f.

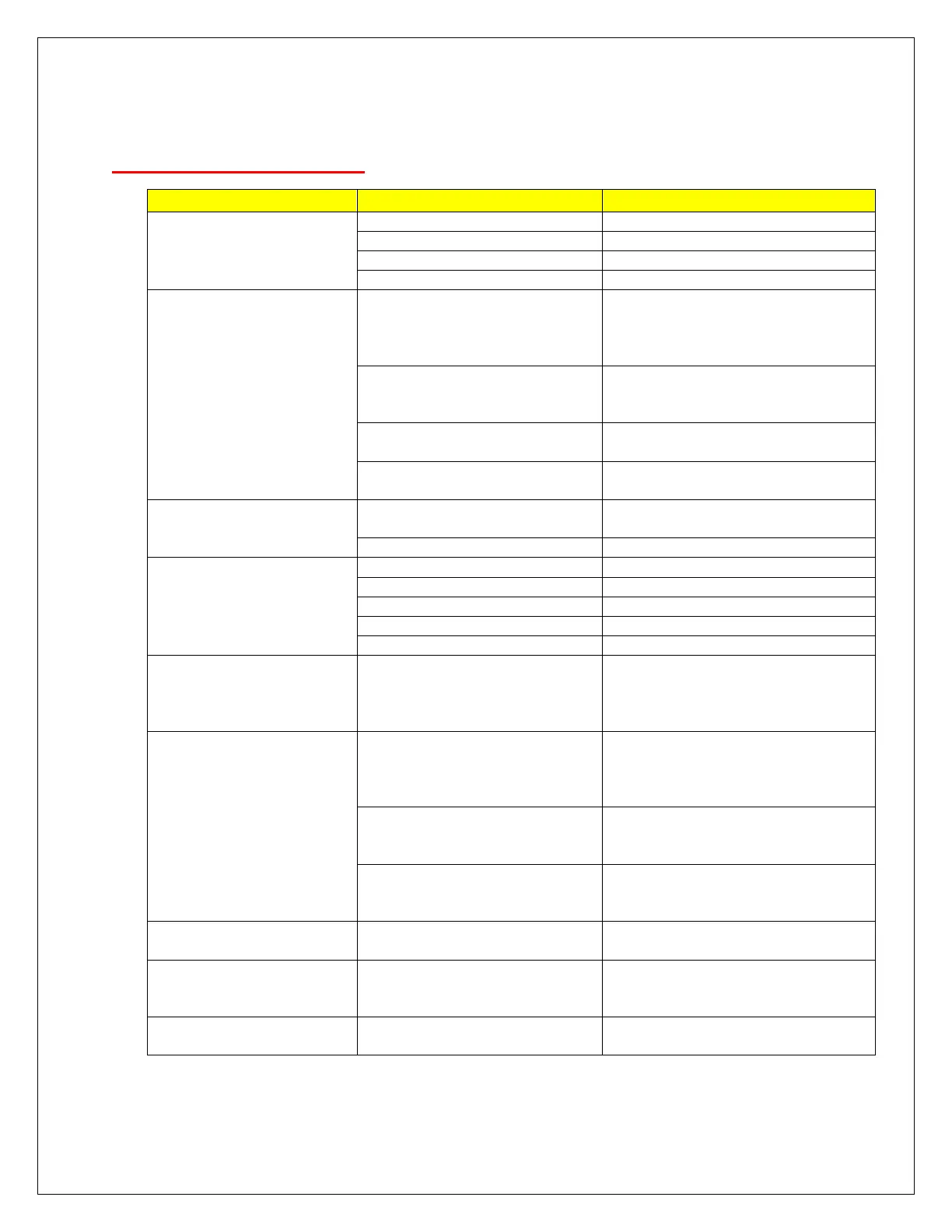

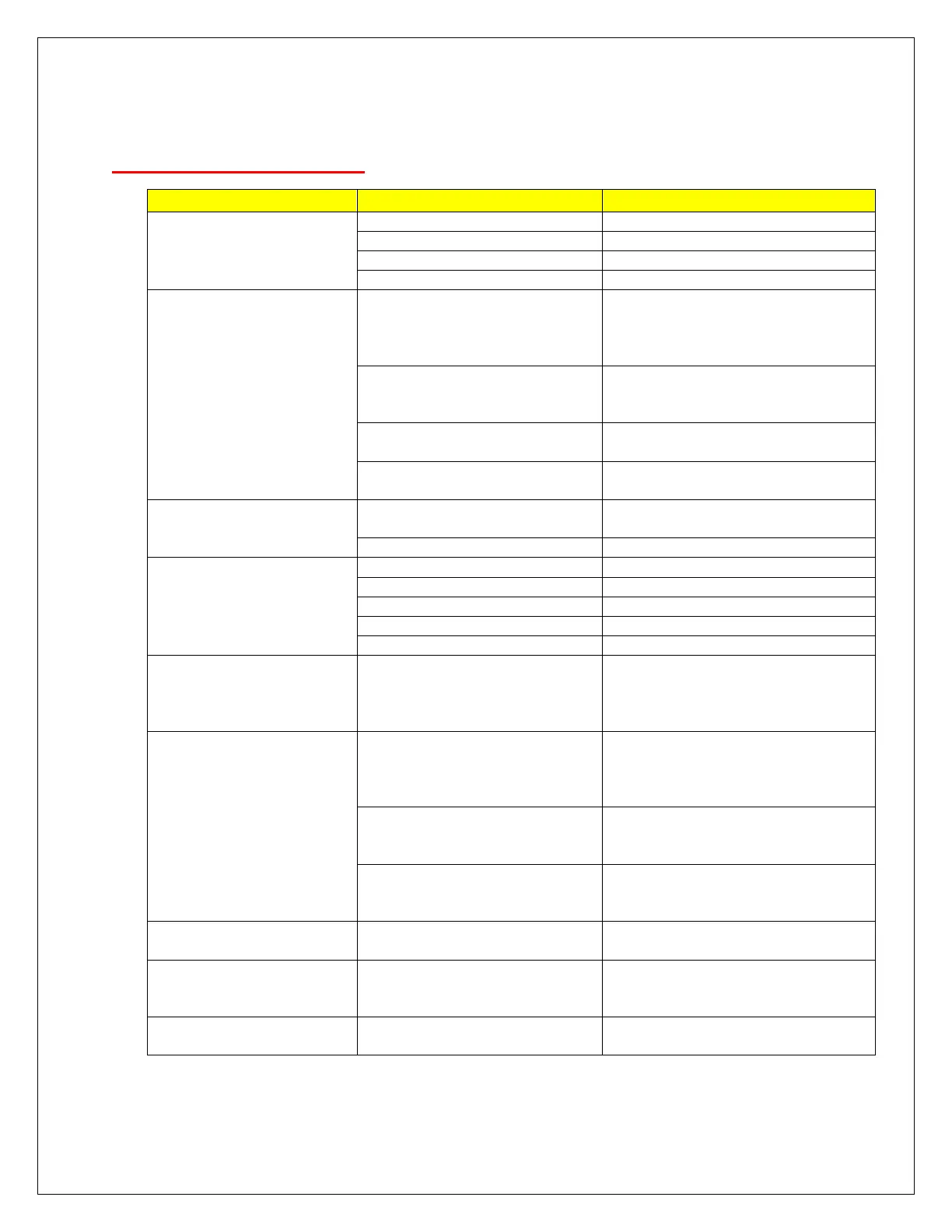

TROUBLESHOOTING

Motor thermal overload tripped

Wait for overload to cool

Faulty wiring connections

Call electrician for checking

Motor runs but lift does

not rise

A piece of trash is under check

valve

Push handle down and push the up

button at the same time. Hold for

10-15 seconds. This should flush

the system.

The clearance between the

plunger valve of the lowering

handle is too small

Check the clearance between the

plunger valve of the lowering

handle. There should be 1/16”

Dirty on the ball and seat of

check valve

Remove the check valve cover and

clean ball and seat

Oil level too low

Oil level should be just under the

vent cap port when the lift is down

Oil Blows out breather

of power unit

Lift lowered too quickly while

under a heavy load

Remove excessive weight from lift.

Reduce the oil to the oil level

Motor hums and does

not run

Impeller fan cover is dented

Lift Overloaded

Remove excessive weight from lift

Lift Jerks going up and

down

Rails lift all the way to the top and

return to the floor. Repeat 4-6

times. Do not let this overheat

power unit.

Oil Leaks around the tank-

mounting flange. Oil reservoir

overfilled

Check the oil level to the tank. The

level should be two inches below

the flange of the tank. Check with a

screwdriver

Oil leaks around the rod end of

the cylinder. The rod seal of

the cylinder is out

Rebuild or replace the cylinder

Oil leaks around the breather

end of the cylinder. The piston

seal of the cylinder is out.

Rebuild or replace the cylinder

Lift makes excessive

noise

Leg of the lift is dry and

requires grease.

Cylinder pulley assembly or

cable pulley assembly is not

moving freely

Grease the pulley assembly.

May have excessive wear on

pins or cylinder yoke

Replace the pins or cylinder yoke.

Loading...

Loading...