ACAUTION

While

the

chipper

chute

is

removed,

do

not

place

your

hands inside the

chipper

blade accessopening.

The

chipper

blade

that

is

located

inside

the

open-

ing

(on

the

chipper

flyWheel)

is

extremely

sharp

and can

cause

serious

personal

injury.

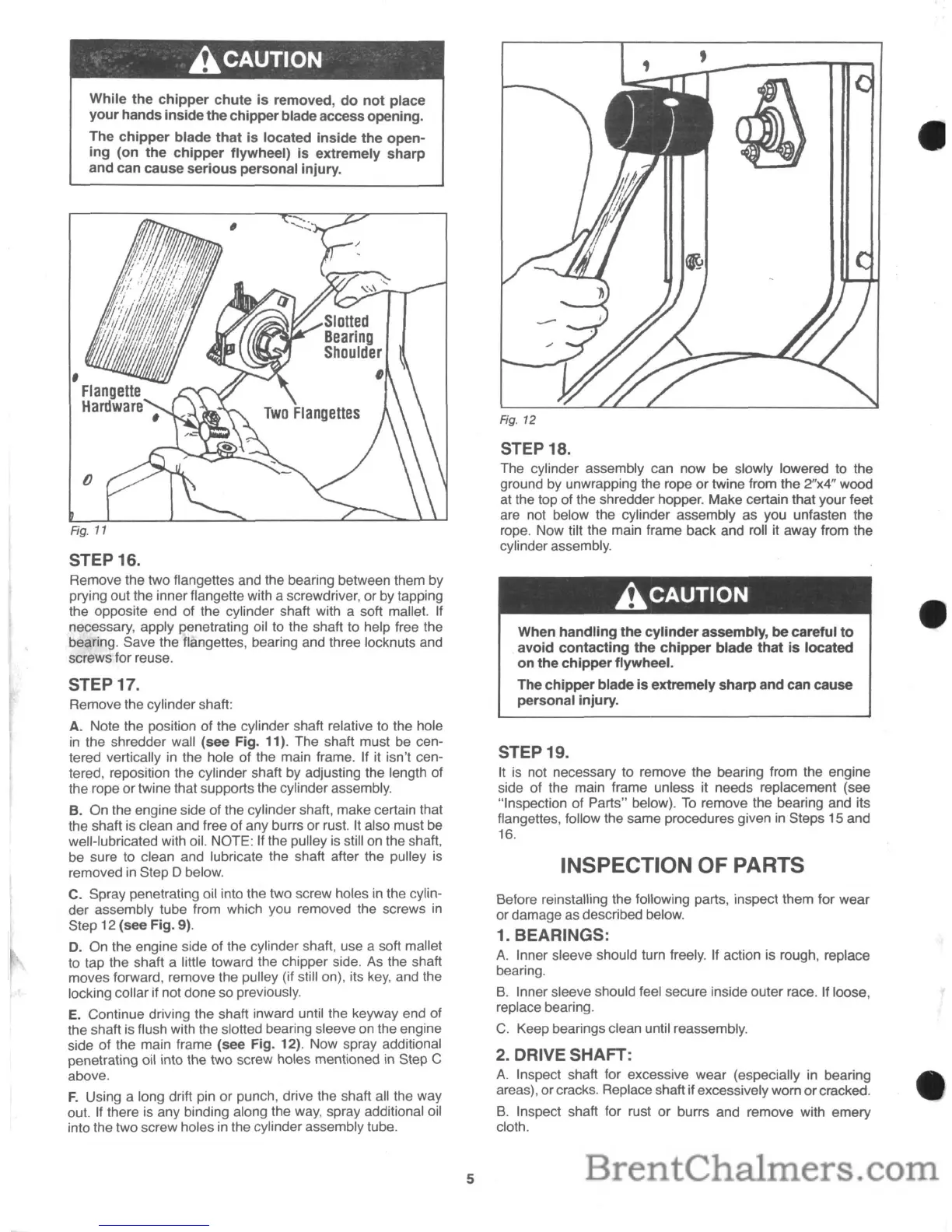

STEP 16.

Remove the two flangettes and the bearing between them by

prying out the inner f1angette with a screwdriver, or by tapping

the opposite end of the cylinder shaft with a soft mallet. If

necessary, apply penetrating oil to the shaft to help free the

bearing. Save the f1angettes, bearing and three locknuts and

screws for reuse.

STEP 17.

Remove the cylinder shaft:

A. Note the position of the cylinder shaft relative to the hole

in

the shredder wall (see Fig. 11). The shaft must

be

cen-

tered vertically

in

the hole of the main frame. If it isn't cen-

tered, reposition the cylinder shaft by adjusting the length of

the rope or twine that supports the cylinder assembly.

B. On the engine side of the cylinder shaft, make certain that

the shaft

is

clean and free of any burrs or rust. It also must be

well-lubricated with oil. NOTE: If the pulley

is

still on the shaft,

be sure to clean and lubricate the shaft after the pulley

is

removed

in

Step D below.

C. Spray penetrating oil into the two screw holes in the cylin-

der assembly tube from which you removed the screws

in

Step 12 (see Fig. 9).

D.

On the engine side of the cylinder shaft, use a soft mallet

to tap the shaft a little toward the chipper side. As the shaft

moves forward, remove the pulley (if still on), its

key,

and the

locking collar if not done so previously.

E.

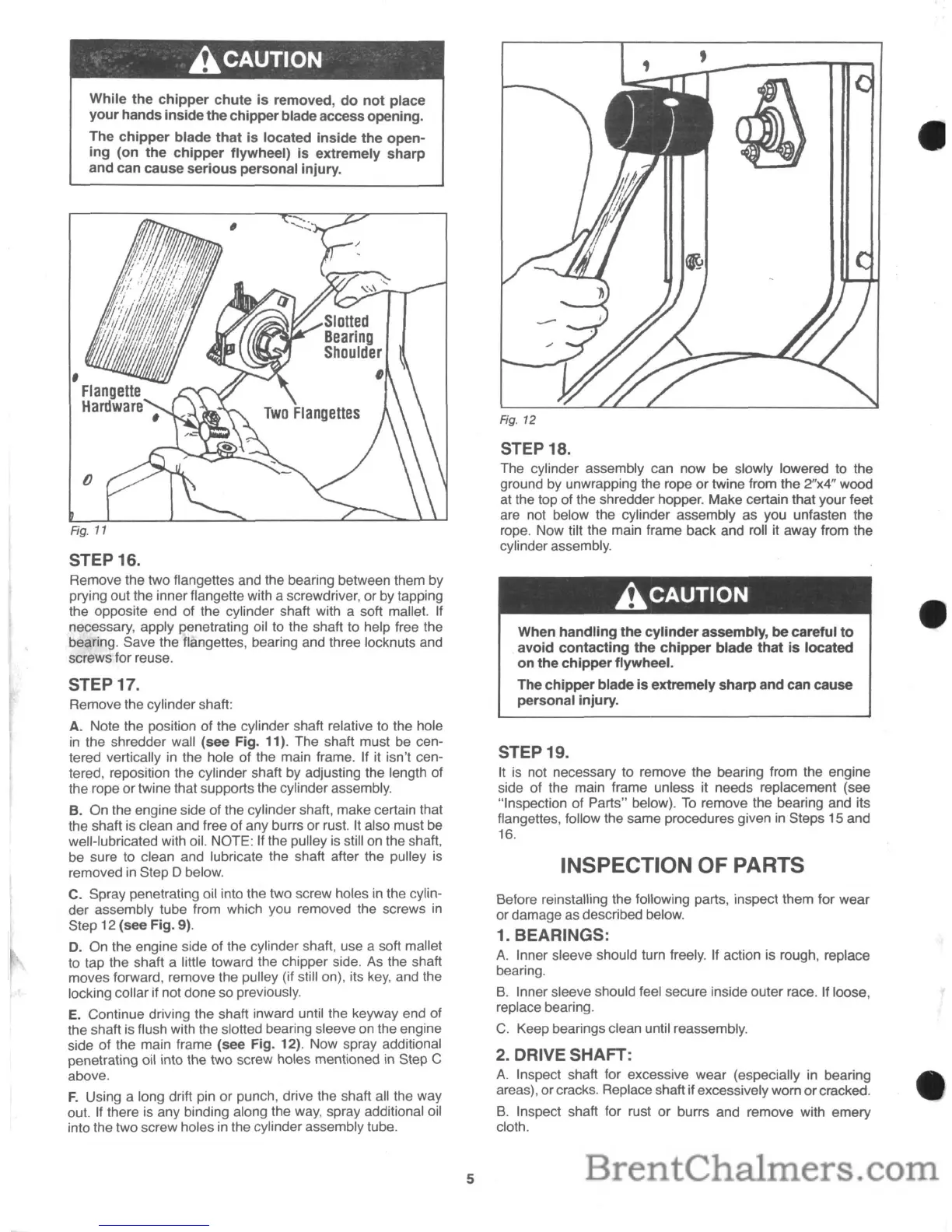

Continue driving the shaft inward until the keyway end of

the shaft

is

flush with the slotted bearing sleeve on the engine

side of the main frame (see Fig. 12). Now spray additional

penetrating oil into the two screw holes mentioned in Step C

above.

F.

Using a long drift pin or

punCh,

drive the shaft all the way

out. If there

is

any binding along the

way,

spray additional oil

into the two screw holes

in

the cylinder assembly tube.

5

Fig.

12

STEP 18.

The cylinder assembly can now be slowly lowered to the

ground by unwrapping the rope or twine from the

2"x4" wood

at the top of the shredder hopper. Make certain that your feet

are not below the cylinder assembly as you unfasten the

rope. Now tilt the main frame back and roll it away from the

cylinder assembly.

ACAUTION

When

handling

the

cylinder

assembly,

be

careful

to

avoid

contacting

the

chipper

blade

that

is

located

on

the

chipper

flywheel.

The

chipper

blade

is

extremely

sharp

and

can cause

personal

injury.

STEP 19.

It

is

not necessary to remove the bearing from the engine

side of the main frame unless it needs replacement (see

"Inspection of Parts" below).

To

remove the bearing and its

f1angettes, follow the same procedures given

in

Steps 15 and

16.

INSPECTION OF PARTS

Before reinstalling the following parts, inspect them for wear

or damage as described below.

1. BEARINGS:

A.

Inner sleeve should turn freely. If action is rough, replace

bearing.

B.

Inner sleeve should feel secure inside outer race. If loose,

replace bearing.

C.

Keep bearings clean until reassembly.

2. DRIVE SHAFT:

A.

Inspect shaft for excessive wear (especially

in

bearing

areas), or cracks. Replace shaft if excessively worn orcracked.

B.

Inspect shaft for rust or burrs and remove with emery

cloth.

Loading...

Loading...