3. CYLINDER ASSEMBLY:

A.

Rotate or replace shredder flail cutters as described

in

Owner/Operator Manual. While doing

so,

check that cylinder

pins are not bent by rolling pins

on

a flat surface. Also: always

use new roll pins coated with Loctite 242 sealant when secur-

ing

the cylinder pins to the cylinder assembly.

B.

Sharpen or replace chipper blade as described

in

Owner/

Operator Manual.

C.

Check weld joints where flywheel and two flat plates join

cylinder assembly

tUbe.

Replace cylinder assembly if cracks

are evident.

D.

Check bore opening at each end of cylinder assembly

tube for burrs or rough edges and remove with metal file or

emery cloth.

E.

Inspect the two bolt holes

in

the center of the cylinder

assembly tube for cracks or excessive wear. Replace cylin-

der assembly if cracked or excessively worn.

F.

Lubricate drive shaft with oil and carefully slide pulley end

of shaft through chipper side of cylinder assembly tube. Shaft

should slide easily through tube. If not, remove shaft and

inspect shaft and tube for burrs or rough edges.

4. DRIVE BELT:

A.

Inspect belt for cracks, cuts, or fraying. Replace belt if

in

poor condition.

5. INSIDE THE

CHAMBER:

A.

While the cylinder assembly

is

removed, now

is

a good

time to clean the inside of your equipment.

B.

Using a wire brush or putty knife, scrape off the built-up

residue that's

on

the inner walls of the chipper/shredder cham-

ber.

Once clean, inspect all interior and exterior welds for

cracks or breaks. It's important for structural integrity that

cracked or broken welds be repaired.

REASSEMBLY

STEP 1.

If the bearing on the engine side of the main frame has been

removed, install a new bearing by following Steps A through

D.

If the bearing has not been removed, proceed

to

Step

2.

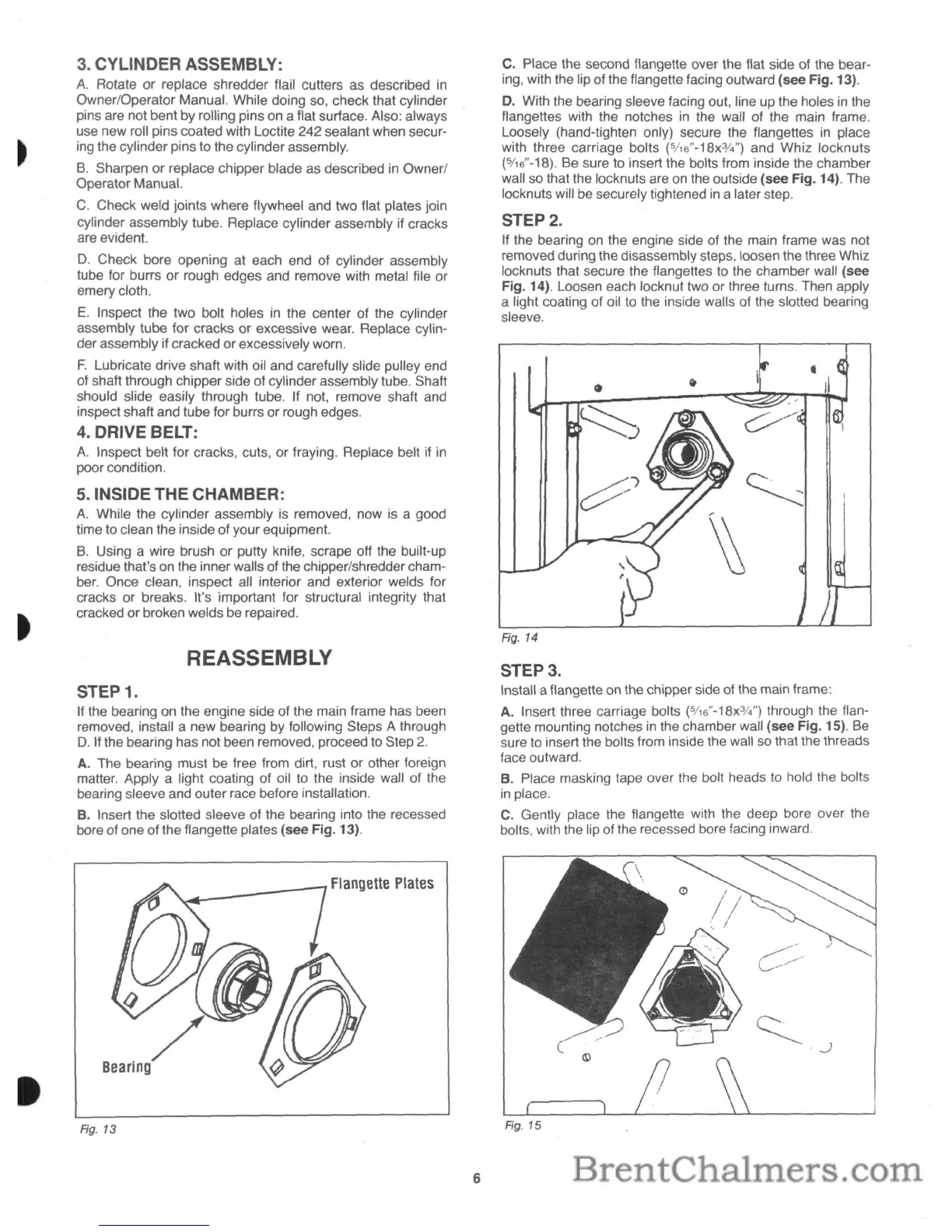

A.

The bearing must be free from dirt, rust or other foreign

matter. Apply a light coating of oil to the inside wall of the

bearing sleeve and outer race before installation.

B.

Insert the slotted sleeve of the bearing into the recessed

bore of one of the flangette plates (see Fig. 13).

"-.....01.-------/

Flangette

Plates

Rg. 13

6

C. Place the second flangette over the flat side of the bear-

ing, with the lip of the

f1angette

facing outward (see Fig. 13).

D.

With the bearing sleeve facing out, line up the holes

in

the

f1angettes

with the notches

in

the wall of the main frame.

Loosely (hand-tighten only) secure the f1angettes

in

place

with three carriage bolts

(5/16"-18x3f4")

and Whiz locknuts

(5/

16

"-18). Be sure

to

insert the bolts from inside the chamber

wall

so

that the locknuts are

on

the outside (see Fig. 14). The

locknuts will be securely tightened

in

a later step.

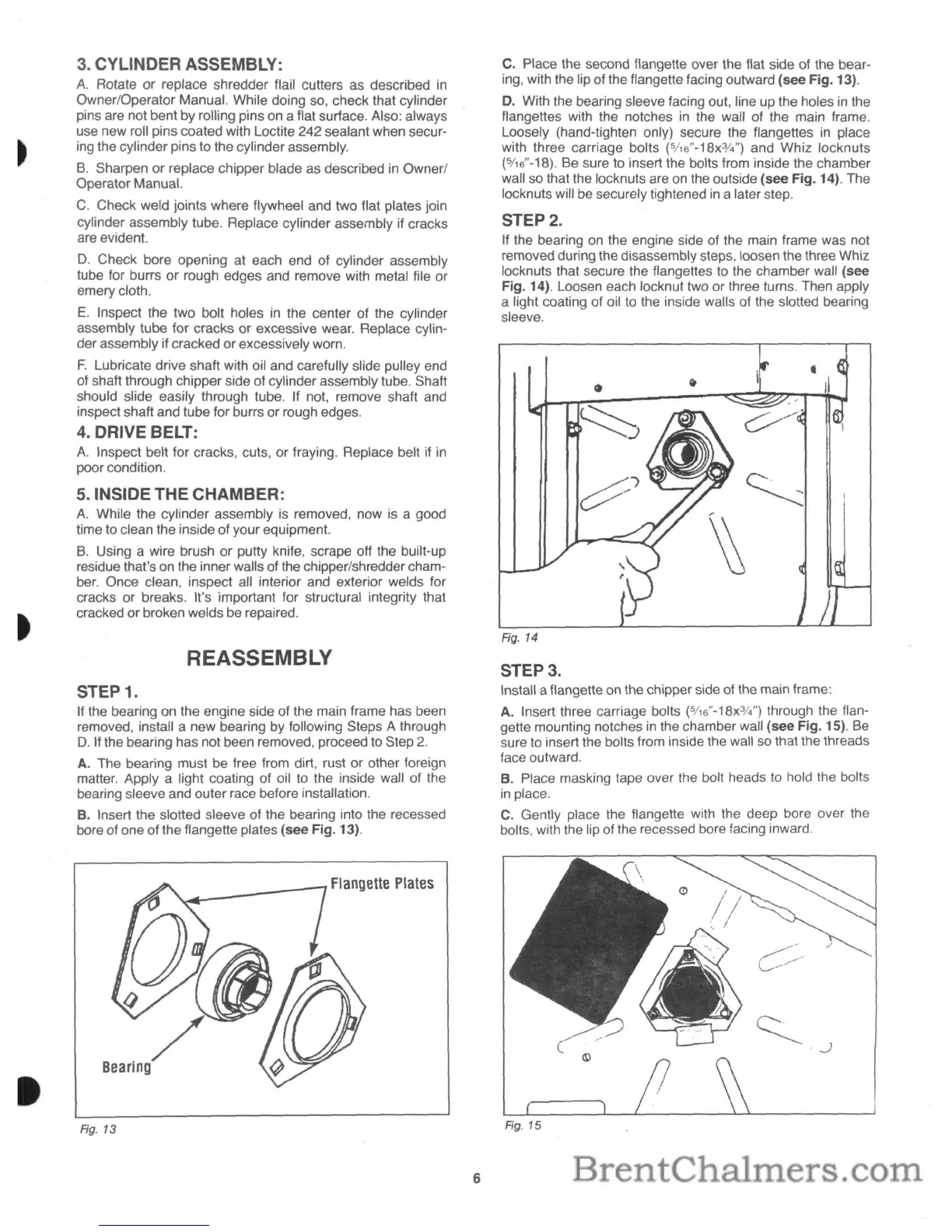

STEP

2.

If the bearing

on

the engine side of the main frame was not

removed during the disassembly steps, loosen the three Whiz

locknuts that secure the flangettes to the chamber wall (see

Fig. 14). Loosen each locknut two or three turns. Then apply

a light coating of oil

to

the inside walls of the slotted bearing

sleeve.

•

Fig. 14

STEP 3.

Install a

f1angette

on the chipper side of the main frame:

A. Insert three carriage bolts

(5I16"-18x3f4")

through the flan-

gette mounting notches

in

the chamber wall (see Fig. 15).

Be

sure

to

insert the bolts from inside the wall

so

that the threads

face outward.

B. Place masking tape over the bolt heads to hold the bolts

in

place.

C.

Gently place the

f1angette

with the deep bore over the

bolts, with the lip of the recessed bore facing inward.

Fig. 15

Loading...

Loading...