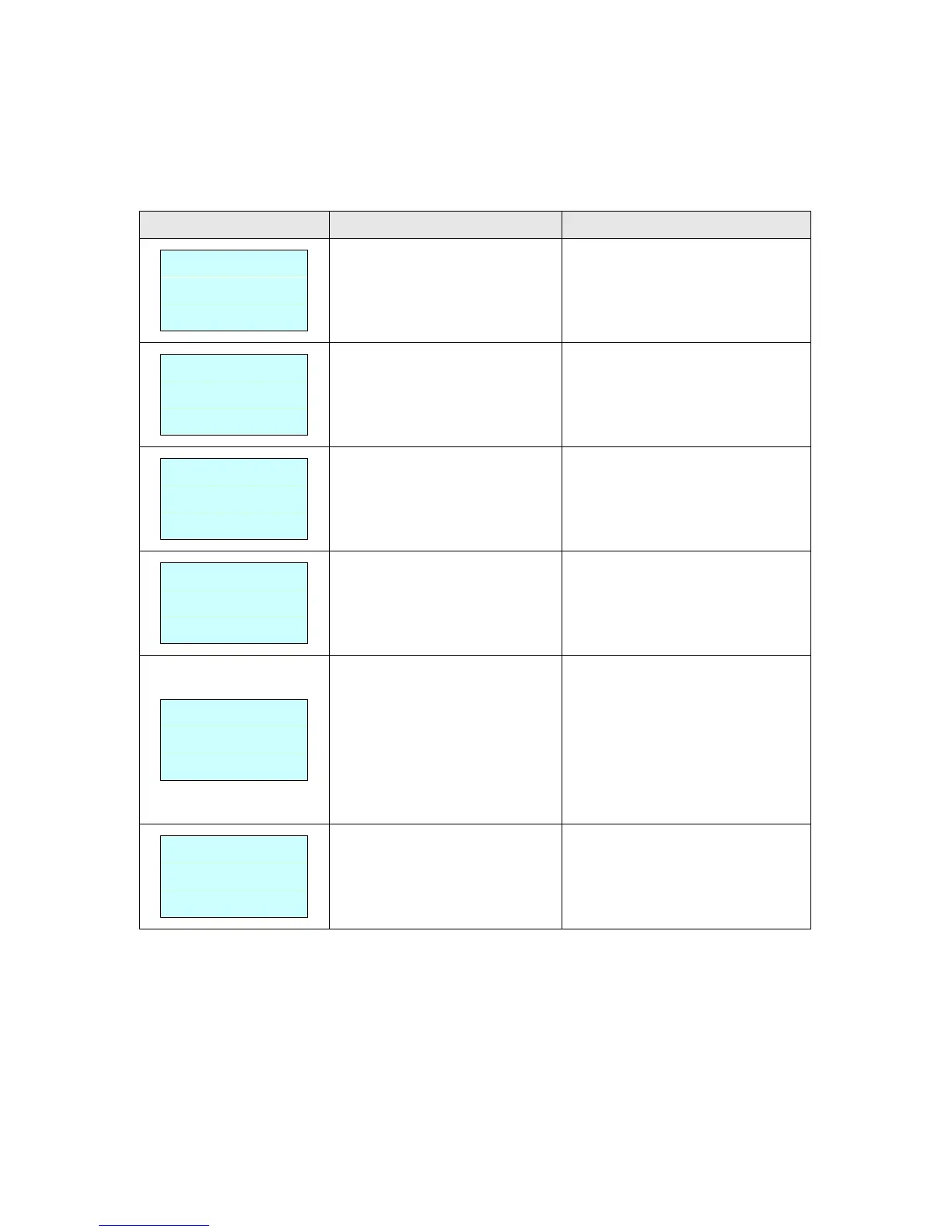

5.3 LCD display (Factory option)

This section lists the LCD display messages that you may encounter when operating the

printer. Also, it provides solutions.

* The printer top cover is open.

* Please close the top cover.

* Running out of label.

* The label is installed incorrectly.

* Gap/black mark sensor is not

calibrated.

* Supply a new label roll.

* Please refer to the steps in user’s

manual to reinstall the label roll.

* Calibrate the gap/black mark

sensor.

* Gap/black mark sensor is not

set properly.

* Make sure label size is set

properly.

* Labels may be stuck inside the

printer mechanism.

* Calibrate the gap/black mark

sensor.

* Set label size correctly.

* The space of FLASH/DRAM or

MicroSD card is full.

* Delete unused files in the

FLASH/DRAM or MicroSD card.

* Peel function is enabled.

Waiting user to take label away

to print the next label.

* Please take the label away to print

the next label if peeler module is

installed.

* If peeler module is installed and

label is been taken away, but the

message remains. Please check if

the peeler module connector is

connected to main board properly.

* If peeler module is not installed,

please disable the peeler function.

* Cutter jam.

* There is no cutter installed on

the printer.

* Cutter or cutter driver circuit

board is damaged.

* Remove the jammed label.

* Make sure the media thickness is

equal or less than 0.19mm.

* Replace the cutter or cutter driver

circuit board.