All rights reserved 8 Installation Guide (en) 1.3.3

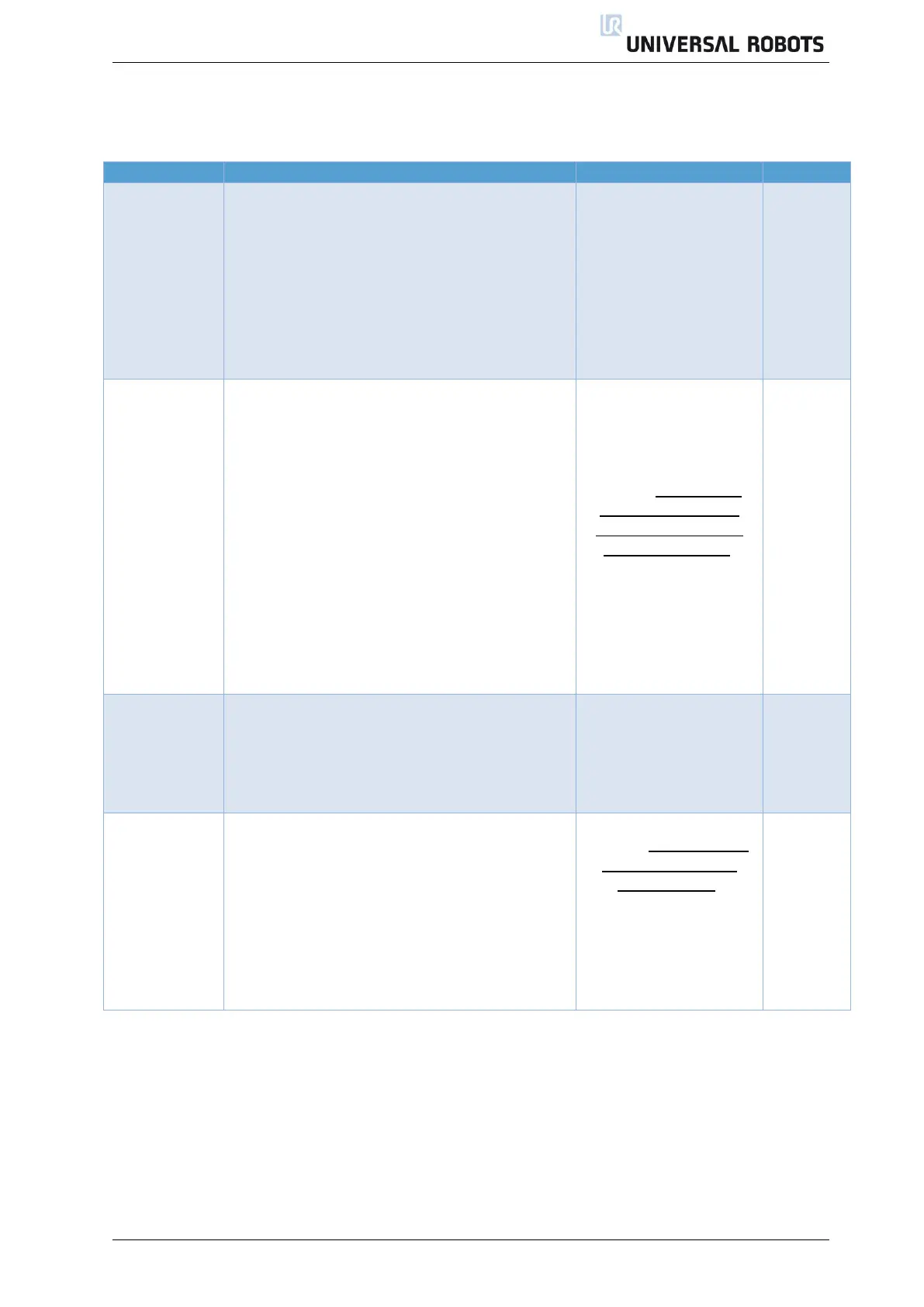

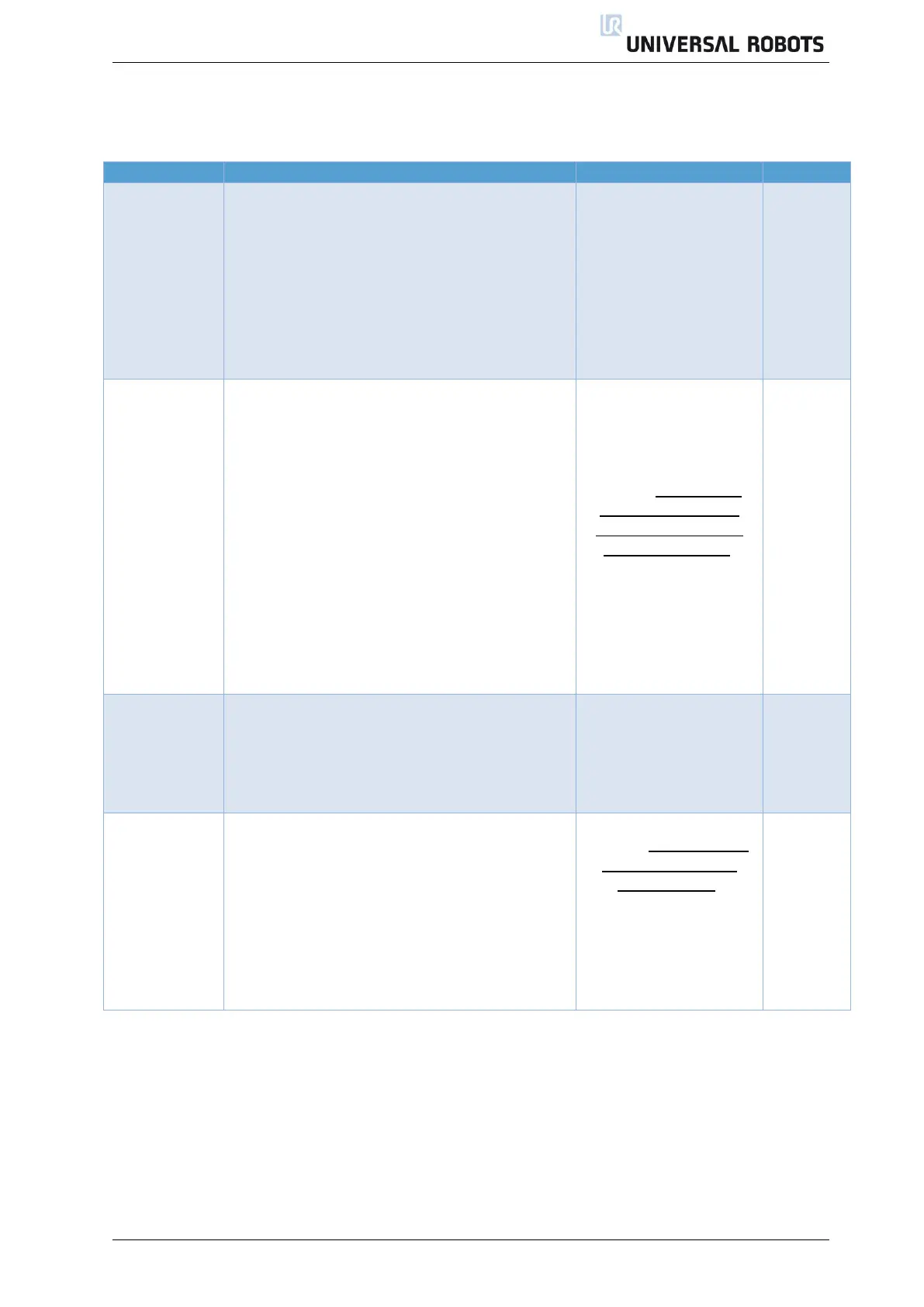

5. I/O Ports

5.1 Inputs and Outputs

Check all terminals for proper connection.

Terminals should not be loose. You should

also take caution that the shield of the wire

(if present) is not contacting any terminal

connections.

Incorrect or loose connection of these

terminals can result in problems with the

signals.

UR User Manual

Chapter “Controller

I/O”

Controller

I/O used?

YES

NO

Be sure that the current per single I/O is not

above the maximum allowed value.

Be sure that the total current used by all I/O

is not above the maximum allowed.

If there is a need for larger current supplying

capacity than can be supplied by internal

power supply unit use an external power

supply unit and make sure the 24 V jumper

is properly configured and that the internal

24 V supply of the robot is not tied to the

external 24 V supply. It is not good practice

to have the outputs of two different 24 V

power supplies connected together.

UR User Manual

Chapter “Controller

I/O”

UR Support Website

Article “Connecting

internal inputs and

outputs (I/O) on the

robot’s controller”

Be sure that the current per single I/O is not

above the maximum allowed value.

Be sure that the total current used by all I/O

is not above the maximum allowed value.

UR User Manual

Chapter “Tool I/O”

Safety

devices

connected?

YES

NO

Check mismatch time settings on safety

signals on external safety devices. Note that

dual channel safety outputs are switched

with a maximum delay of 8 ms within the

UR robots safety IO and an internal error

message is triggered after 48 ms. A value of

20 ms is recommended for setting the

mismatch on safety inputs on external

devices (like Safety PLCs).

UR Support Website

Article “Scan time for

CB3 and e-Series

controller I/O”

Loading...

Loading...