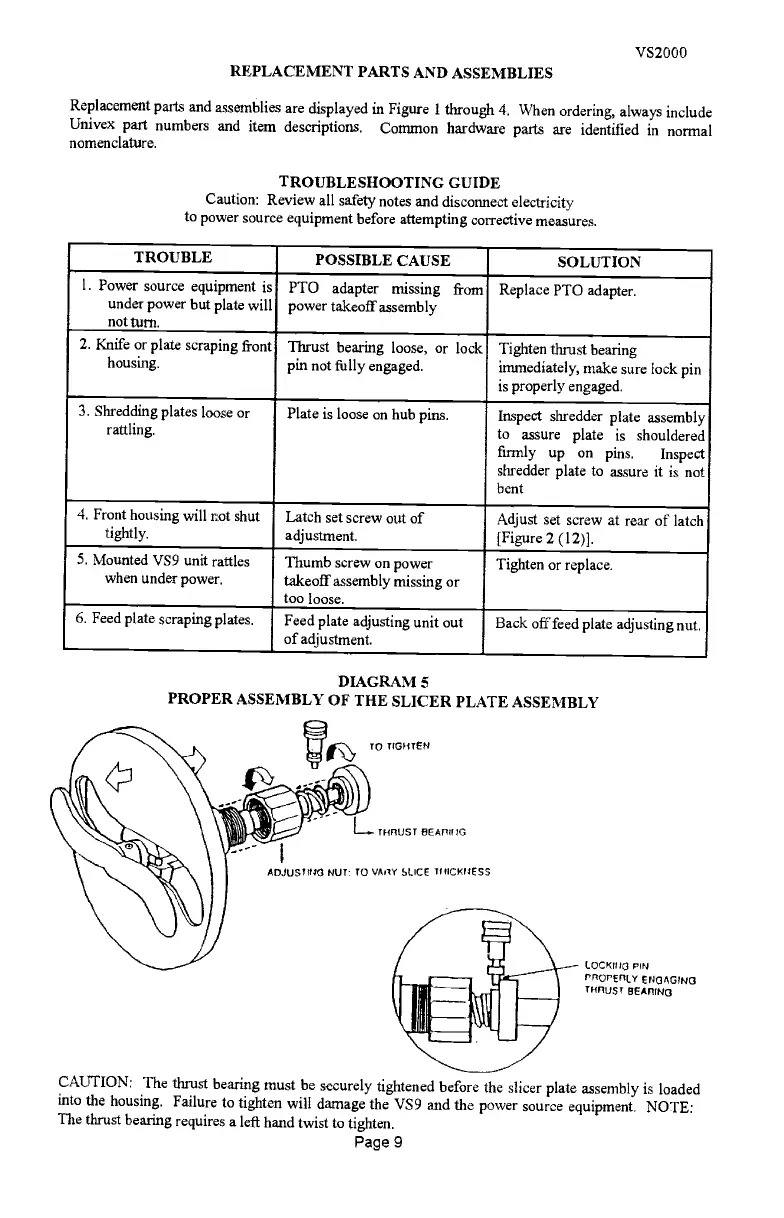

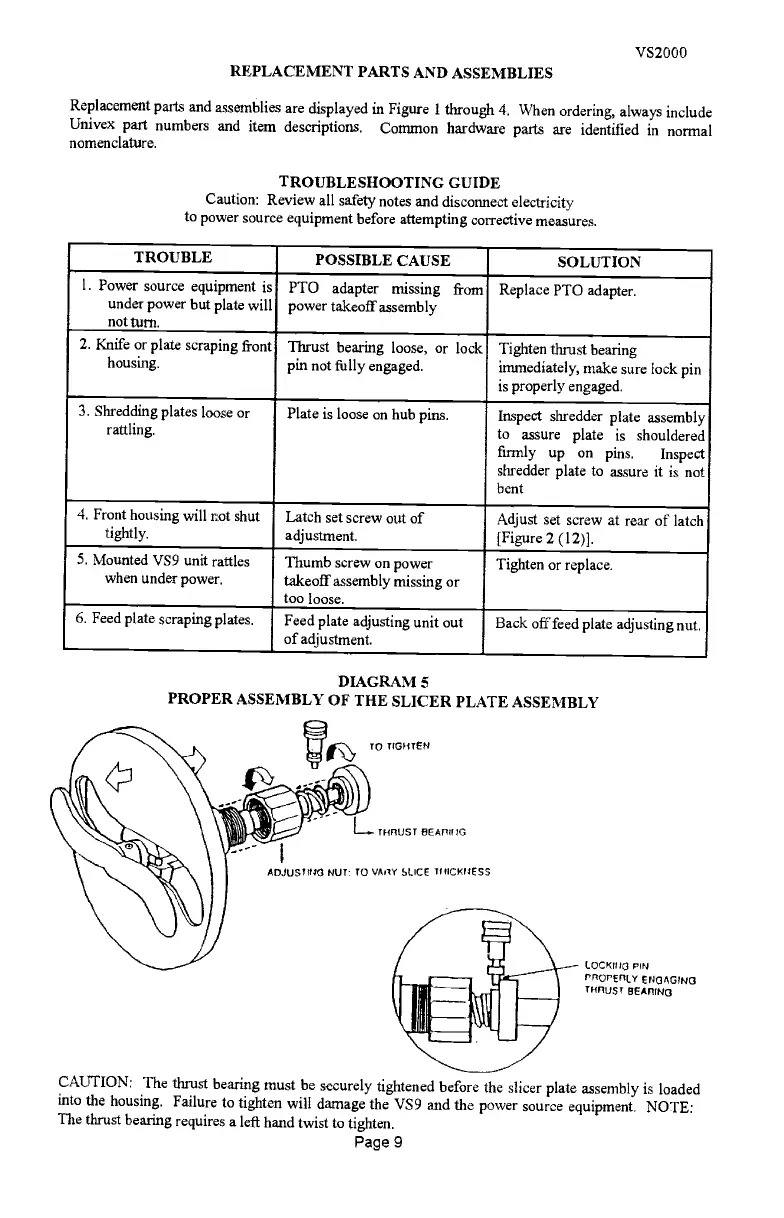

DIAGRAM 5

PROPER ASSEMBLY OF THE SLICER PLATE ASSEMBLY

THflUST EEATIUIG

ADJUSTING NUT: 10 VA1Y SUCE 1I4ICTIESS

VS2000

REPLACEMENT PARTS AND ASSEMBLIES

Replacement parts and assemblies are displayed in Figure 1 through 4. When ordering, always

include

Univex part numbers and item descriptions.

Common hardware parts are identified in normal

nomenclature.

TROUBLESHOOTING GUIDE

Caution: Review all safety notes and disconnect electricity

to power source equipment before attempting corrective measures.

IOCI<ITIG PIN

PPOT'ETT(Y ENGAGING

n-must

BEAnI NG

CAUTION: The thrust bearing must be securely tightened before the slicer plate

assembly is loaded

into the housing. Failure to tighten will damage the VS9 and the

power source equipment. NOTE:

The thrust bearing requires a left hand twist to tighten.

Page 9

TROUBLE

-

POSSIBLE CAUSE

SOLUTION

1. Power source equipment is

under power but plate will

notturn.

PTO adapter

missing from

power takeoff assembly

Replace PTO adapter.

2. Knife or plate scraping front

housing.

Thrust bearing loose, or lock

pin not fully engaged.

Tighten thrust bearing

immediately, make sure lock pin

is properly engaged.

3. Shredding plates loose or

rattling,

Plate is loose on hub pins.

Inspect shredder plate assembly

to

assure

plate

is

shouldered

firmly up on pins.

Inspect

shredder plate to assure it is not

bent

4. Front housing will not shut

tightly.

Latch set screw out of

adjustment.

Adjust set screw at rear of latch

[Figure 2 (12)].

5. Mounted VS9 unit rattles

when under power.

Thumb screw on power

takeoff assembly missing or

too loose.

Tighten or replace.

6. Feed plate scraping plates.

Feed plate adjusting unit out

of adjustment.

Back off feed plate adjusting nut.

PDF compression, OCR, web optimization using a watermarked evaluation copy of CVISION PDFCompressor

Loading...

Loading...