c

e

r

t

i

f

i

e

d

Q

M

-

S

y

s

t

e

m

g

e

p

r

ü

f

t

e

s

Q

M

-

S

y

s

t

e

m

ISO 9001

EN 29001

Installation, Operating, and Maintenance Instructions

Series 64.1

VAT Vakuumventile AG, CH-9469 Haag, Schweiz

Tel ++41 81 771 61 61 Fax ++41 81 771 48 30 Email reception@vat.ch http://www.vatvalve.com

225590EE

2005-04-26

4/16

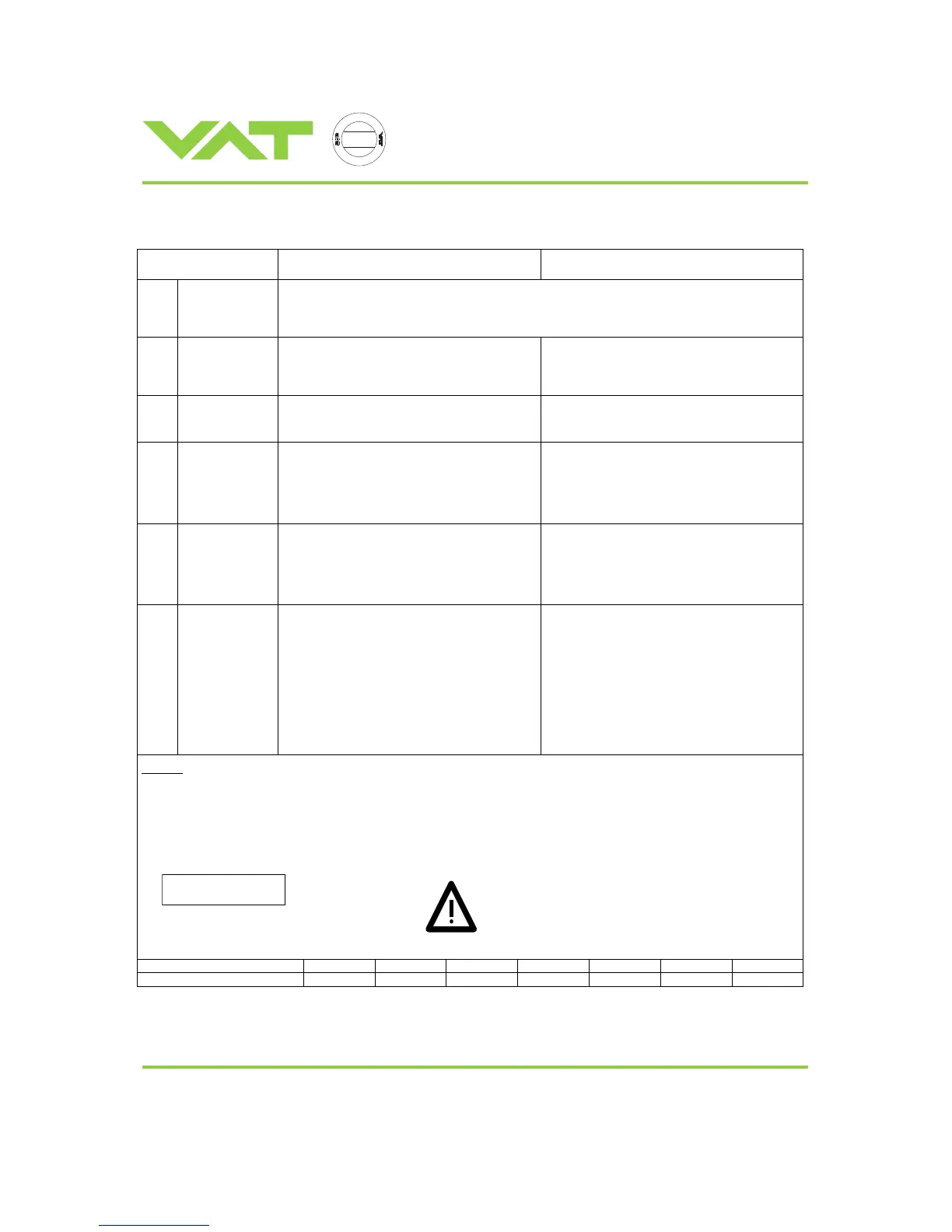

2.3 PM Configuration (setup sequence)

STEP

LOCAL MODE (PM-4 in combination with

Service Box only)

REMOTE MODE (PM-5 if interface installed

only)

1

POWER ON

1. PM controller: Turn on power switch at the rear panel of the PM controller. Note: Valve will close, if not in

closed position

2. On PM-5 or Service Box start-up display (Software version, type of interface, etc.) appears, until valve is in

closed position

3. CLOSE(D) is displayed, otherwise please refer to chapter ‘6 Trouble Shooting’.

2

SELECT

MODE

Select LOCAL operation by pressing «LOCAL» key for 2

seconds.

Select REMOTE operation by pressing «REMOTE» key

on front panel or Service Box for 2 seconds or select

remote operation through RS232 (see ‚9.3.1 Control

commands’) or logic interface (see ‚9.1.3.1 Logic

interface‘)

3

AUTOMATIC

SIZE

ADJUSTMENT

Press simultaneously «OPEN» and «CLOSE» keys for 2

seconds. The controller will perform an automatic size

adjustment procedure to determine open and closed

position and the range between the two positions.

Send RS232 command:

J:<CR><LF> (see ‚9.3.1 Control commands’)

or use Logic command (see ‚9.1.3.1 Logic interface‘)

4

SENSOR

SETUP

1)

Press simultaneously «LEARN» and «ZERO» key for 2

seconds (notation used hereafter: «&», e.g. «LEARN» &

«ZERO»). Then, use «↑» and «↓» key to change

parameters (VOLTAGE RANGE; DISPLAY RANGE;

DISPLAY UNIT; GAIN FACTOR; SENSOR TYPE; ZERO

ADJUST) for each sensor. Toggle with «F1» key to the

next setup parameter. Press «F2» , when finished.

See ‚9.3.3 Sensor setup command‘

Example:

Sensor 1, Voltage Range: 0-10V; Display Range: 0-10;

Display Unit: Torr; Gain Factor: 1; Sensor Type: Torr;

Zero Adjust: enabled;

s:1332010<CR><LF>

Mind: Not possible to do by a logic interface.

5

ZERO ADJUST

(Offset

compensation of

sensor output)

Evacuate process chamber to high vacuum. When the

base pressure is reached, press «ZERO» key for 2

seconds to reset the offset of the pressure sensor.

Disable ZERO function in SENSOR SETUP, if the base

pressure of your system is higher than 1‰ of sensor full

scale.

Evacuate process chamber to high vacuum. When the

base pressure is reached send RS232 command:

Z:<CR><LF> (see ‚9.3.1 Control commands’)

or use Logic command (see ‚9.1.3.1 Logic interface‘).

Disable ZERO function in SENSOR SETUP, if the base

pressure of your system is higher than 1‰ of sensor full

scale.

6

LEARN

2)

(Determination of

control

characteristics of

your process

chamber)

Process chamber at high vacuum, control valve is open:

Open gas inlet and set gas flow (see recommendation

below). Press «LEARN» key for 3 seconds to perform

the autolearning routine of the PM controller. The

autolearning routine may take several minutes and can

be aborted by pressing the «F1» key. A single full run of

the autolearning routine is required to ensure fast and

accurate pressure control.

Note: It is not necessary to repeat LEARN, if the

sensor setup is changed, or if the second

sensor is selected for pressure control. The

controller covers 5% to 5000% of the gasflow

which was used at LEARN.

Process chamber at high vacuum, control valve is open:

Open gas inlet and set gas flow (see recommendation

below). Then send RS232 LEARN command:

L:001000<CR><LF> (‚9.3.1 Control commands’)

or Logic command (see ‚9.1.3.1 Logic interface‘).

The autolearning routine may take several minutes. A

single full run of the autolearning routine is required to

ensure fast and accurate pressure control.

Note: It is not necessary to repeat LEARN, if the

sensor setup is changed, or if the second

sensor is selected for pressure control. The

controller covers 5% to 5000% of the gasflow

which was used at LEARN.

Legend:

1)

The default GAIN FACTOR is 1.00. See chapter ‚9.3.3 Sensor setup command‘ if resetting is necessary.

gain factor > 1 means: faster control but higher overshoot of pressure

gain factor < 1 means: slower control but lower overshoot of pressure

Just 98% of sensor pressure range can be used during control.

If no sensor is used, select as display parameter ‘POS’.

2)

Ideal gasflow for autolearning

Q = 40

•

p

SFS

•

L

min

Q...........gasflow for autolearning [sccm]

p

SFS

.......sensor full scale pressure [Torr]

L

min

........min. controllable conductance [l/s]

Do not use a different gasflow than

recommended for autolearning otherwise

pressure control performance may be insufficient.

valve size DN63 DN100 DN160 DN200 DN250 DN320 DN400

min. controllable conductance 0.6 l/s 1 l/s 1.6 l/s 2 l/s 2.5 l/s 3.2 l/s 4 l/s

Loading...

Loading...