c

e

r

t

i

f

i

e

d

Q

M

-

S

y

s

t

e

m

g

e

p

r

ü

f

t

e

s

Q

M

-

S

y

s

t

e

m

ISO 9001

EN 29001

Installation, Operating, and Maintenance Instructions

Series 64.1

VAT Vakuumventile AG, CH-9469 Haag, Schweiz

Tel ++41 81 771 61 61 Fax ++41 81 771 48 30 Email reception@vat.ch http://www.vatvalve.com

225590EE

2005-04-26

7/16

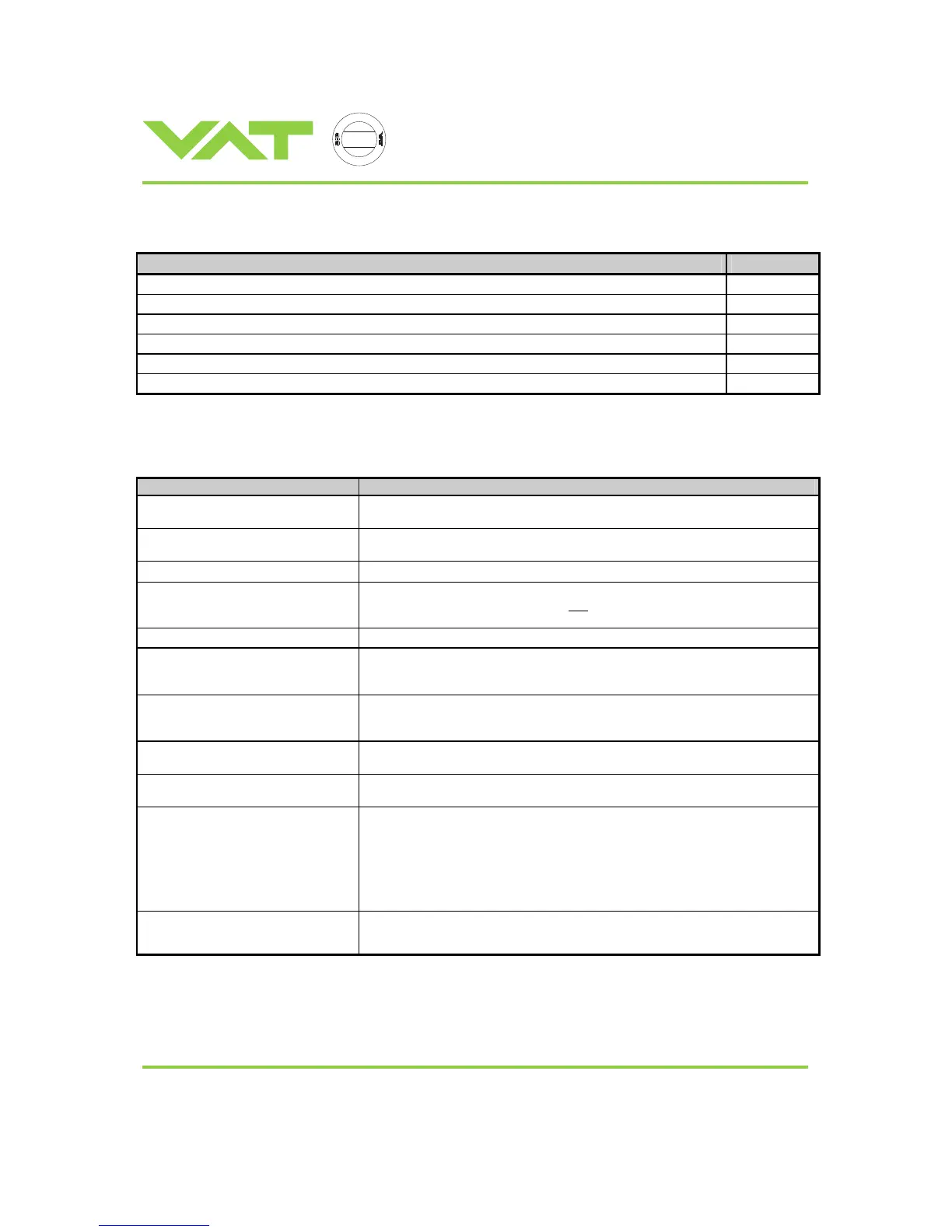

5 Spare Parts / Retrofit Options

Description Ordering No.

Preventive maintenance kit for PM controller with power-fail option, consisting of: SRAM, battery pack, label 86705-R1

Preventive maintenance kit for PM controller without power-fail option, consisting of: SRAM, label 86706-R1

Battery pack for power-fail option, for retrofit 67786-R1

LOGIC interface 207806

RS232C interface 75944-R1

Service Box for PM-4 600BS-29NN

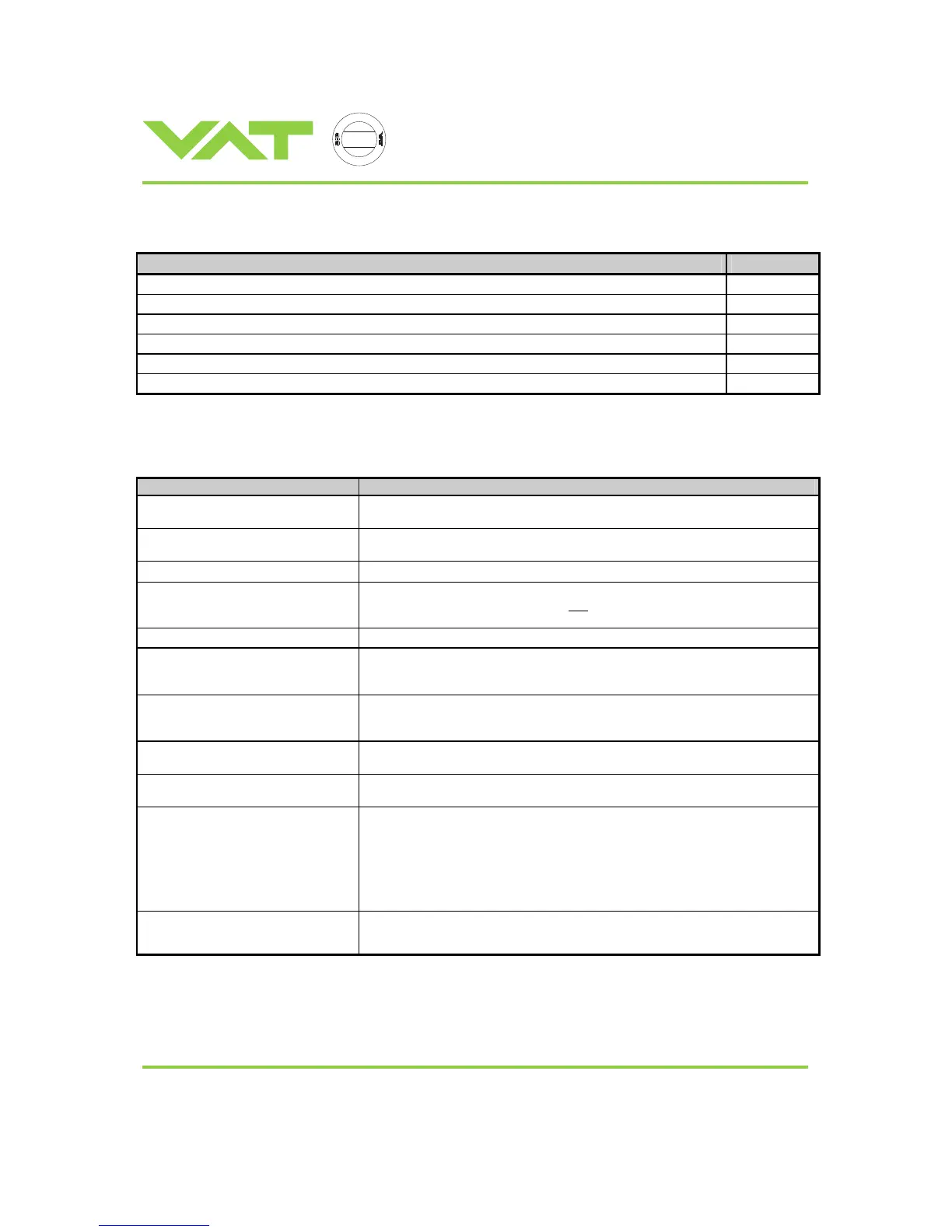

6 Trouble Shooting

Problem Recommendation

Front panel:

LED’s and LCD display inactive

- Check, if mains switch is on, mains cable is connected, mains supply is on

- Check fuses at rear panel of PM controller

Control does not respond to keyboard

commands

- Control in REMOTE, switch PM controller to LOCAL

No or weak text on LCD display

- Adjust brightness; «F1» & «F2» & «↑» key

‘PAR:ER’ or flashing ‘P’ displayed

- New auto learning should be performed

- If error occurs after new auto learning and

power disruption, replace battery powered

SRAM memory

‘ROM:ER’ displayed - EPROM defective, to be changed

LED on «CLOSE» key is flashing, valve

is closed and does not respond to RS 232

or keyboard commands

- Logic CLOSE input on RS 232 interface is active

Pressure reading is wrong

Negative pressure reading

- Confirm that sensor setup is correct, press «LEARN» & «ZERO»

- When base vacuum is reached and pressure reading is off, perform ZERO command

ZERO command does not work - Valve is not in open position, OPEN valve and bring chamber to high vacuum

- ZERO command is disabled, check sensor setup («LEARN» & «ZERO»)

Display not ‘0’ after ZERO command - Sensor offset voltage is larger than ±1.4V

- System not pumped to base pressure

Pressure control not optimal after LEARN

command

- The PM controller reoptimizes the parameters for each set point, repeat pressure

control command after adaption is completed

- ZERO command was not performed before LEARN command

- LEARN command was performed with different gas flow, repeat LEARN sequence

- Make sure sensor range is suited for application (>3% of f.s.)

- Noise on sensor signal, check sensor voltage, make sure a shielded sensor cable is

used

Valve open or in control mode

‘E’ displayed on front panel

- Pendulum plate does not reach end position because of mechanical obstruction.

- Check valve installation (torque on valve flange mounting screws too high, see

Installation and Operating Instruction for valve!). Check and clean valve

Loading...

Loading...