25

Bar Maintenance

Bar Maintenance Essentials

Turn the bar over each time the chain is replaced, this will ensure even wear on both

sides of the bar.

Regularly clean the bar guide groove, oil inlet and grease port.

The groove depth must not be less then 6.0mm of a 18" 0.325" chain - minimum 1mm

clearance from the drive link to the guide rail.

Always remove burred edges with a flat file working from the outside in.

Bar Maintenance Guide

1. Remove bar from chainsaw, ensuring spark plug cap is removed before commencing

maintenance.

2. Secure bar in a vice.

3. Clean the guide rail groove of the bar ensure you do not damage the guide rails in the

process.

4. Clean the oil inlet port and the grease hole.

5. Remove all burrs from the guide rails, working from the outside in.

6. Clean the entire bar using degreaser and a scrubbing brush removing all grease, grime,

metal shaving, etc.

7. Check over the bar to ensure all burrs have been removed, the bar is free from grease, grime

and metal shaving and both oil and grease holes are clear.

8. Once the chainsaw is assemblied, check the chain and bar are recieving adequate oil.

Always use cut resistant gloves when performing maintenance on the chainsaw.

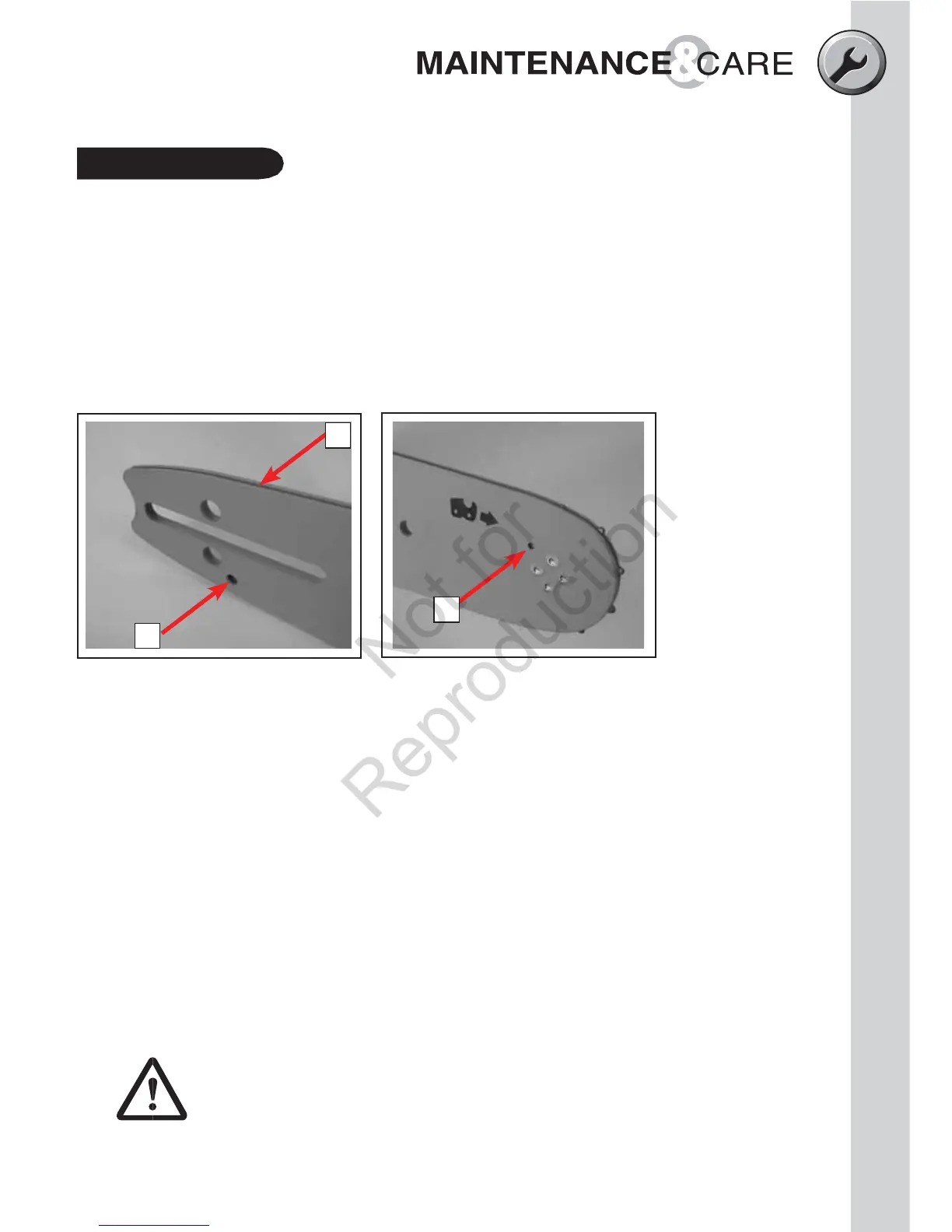

(A) Guide bar groove

(B) Oil inlet port

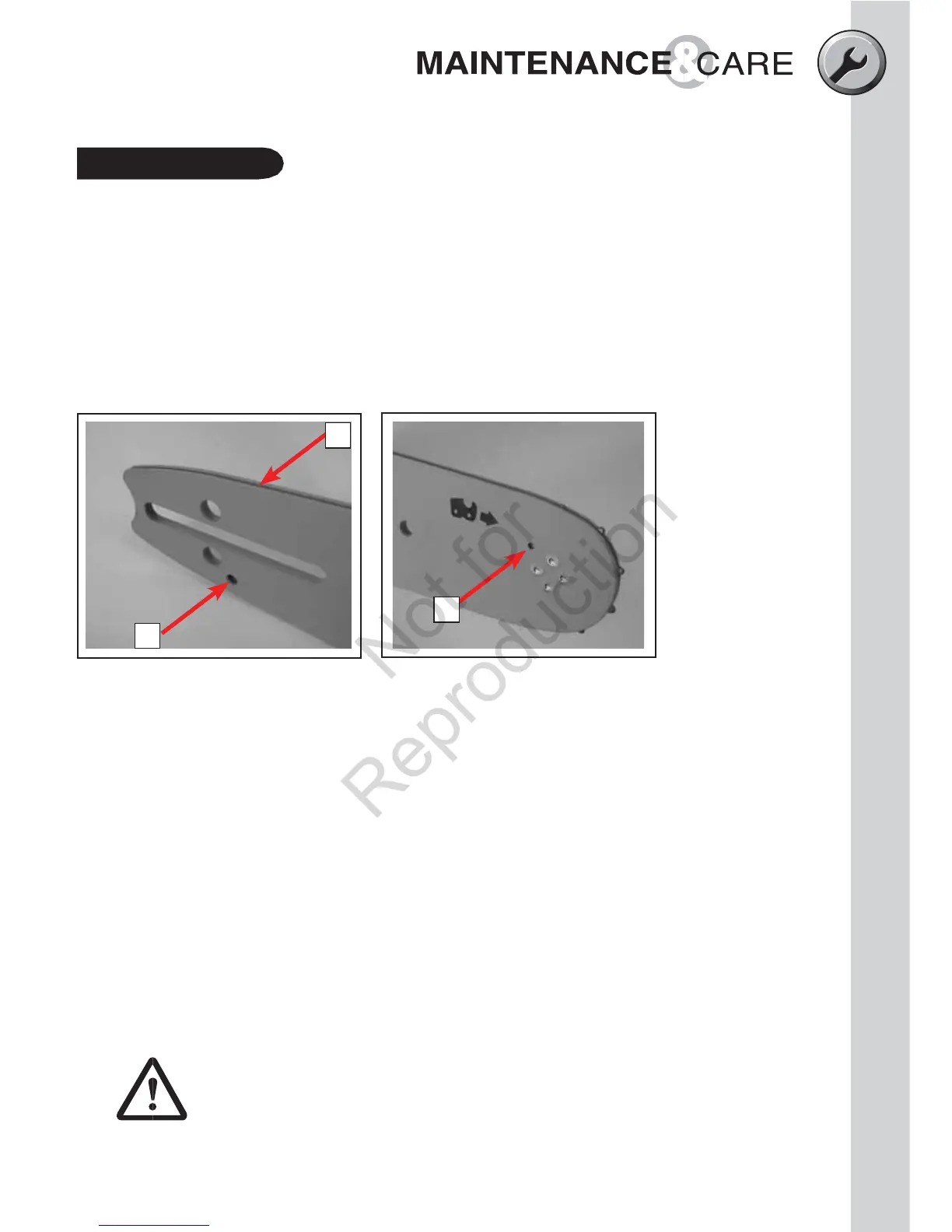

(C) Grease port

A.

B.

C.

Loading...

Loading...