28

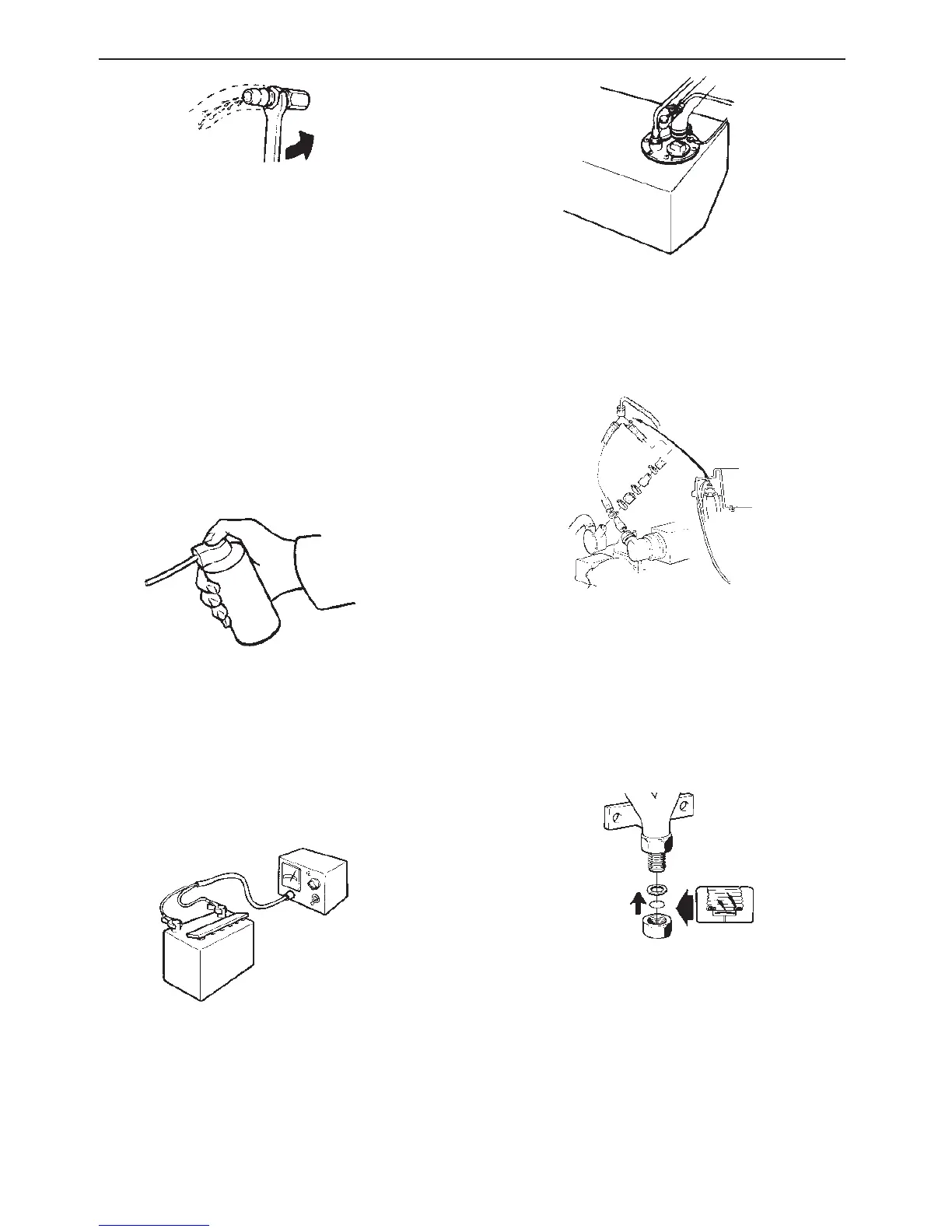

Remove the batteries from the boat. Clean them and

store them in a cool, dry place. Check that the batter-

ies are well charged. Trickle charge them according to

the manufacturer’s instructions (a flat battery can

easily be damaged as a result of freezing).

If the engine has a vacuum valve it must be taken

apart twice a season or whenever leaks occur.

Remove the entire valve from the bulkhead where it is

fitted.

Loosen the valve cover and remove the gasket and

diaphragm and clean out any deposits. Deformed

diaphragms must be replaced.

Installation should be done with the valve upside

down. Place the diaphragm in the cover. Ensure that

the entire diapragm is placed in the right location. The

diaphragm must not be trapped by the gasket. Insert

the gasket and screw on the cover.

CAUTION: Tighten torque 2 Nm (1.47 ft.Ibs). If the

cover is tightened too hard the valve will stop working.

There is no need to drain off this combined anti-

corrosion and anti-freezing mixture. If inhibiting is

done with emulsifying oils, there is no protection

against freezing, and the seawater system must

therefore be drained off. Check that the water runs

out, since dirt can block the cocks. Then close all

cocks. Remove the cover from the seawater pump.

Remove the impeller and rinse it in freschwater. Keep

the impeller in a sealed plastic bag during laying-up if

it is in good condition. (Otherwise fit a new impeller

when launching the boat)

Drain off any water or sediment from fuel tanks. Top

up all fuel tanks to prevent condensation during

storage period.

Clean the outside of engine, and reverse gear/S-

drive. Touch-up any bare patches in the paintwork

with Volvo Penta original paint. Spray the compo-

nents of the electrical system, and all the control

components with anti-moisture spray. All engine

control linkages should be inspected for wear, proper-

ly adjusted and protected from corrosion.

Loading...

Loading...