30

Painting

Check the painting of the S-drive. Touch up dam-

aged areas using Genuine Volvo Penta drive Paint.

Then coat the drive with a Teflon

®

* agent for alumini-

um drives. We recommend the Volvo Penta Anti-

fouling Agents (part No. 1141593-2 or 1141594-0).

These products are specially designed for the S-drive

and are at the same time as kind to the environment as

possible.

Paint the bottom of the boat and the propeller using a

suitable anti-fouling paint or with a pure Teflon

®

agent.

All anti-fouling paints are poisonous and by definition

more or less harmful to our marine environment. Avoid

such products. Most countries have a legislation which

controls the usage of anti-fouling boat bottom paints.

Always make sure you follow these regulations! In

some countries it is forbidden to use anti-fouling paints

on leisure crafts, e.g. in freshwater.

We recommend simple Teflon

®

treatment in combina-

tion with mechanical cleaning a few times during the

season, especially in the case of smaller boats which

are easy to lift.

This may be impractical for larger boats. Also, if the

boat is in water which promotes fouling, an anti-fouling

paint may need to be used after all. In this case, use a

pure copper-based anti-fouling paint which contains

copper thiocyanate (not copper oxide).

Tin-based paints (TBT paints) must not be used!

Bear in mind the legislation in force for the area in

which the boat is used.

NB. Unsuitable bottom paints may cause great corro-

sion damage to the S-drive.

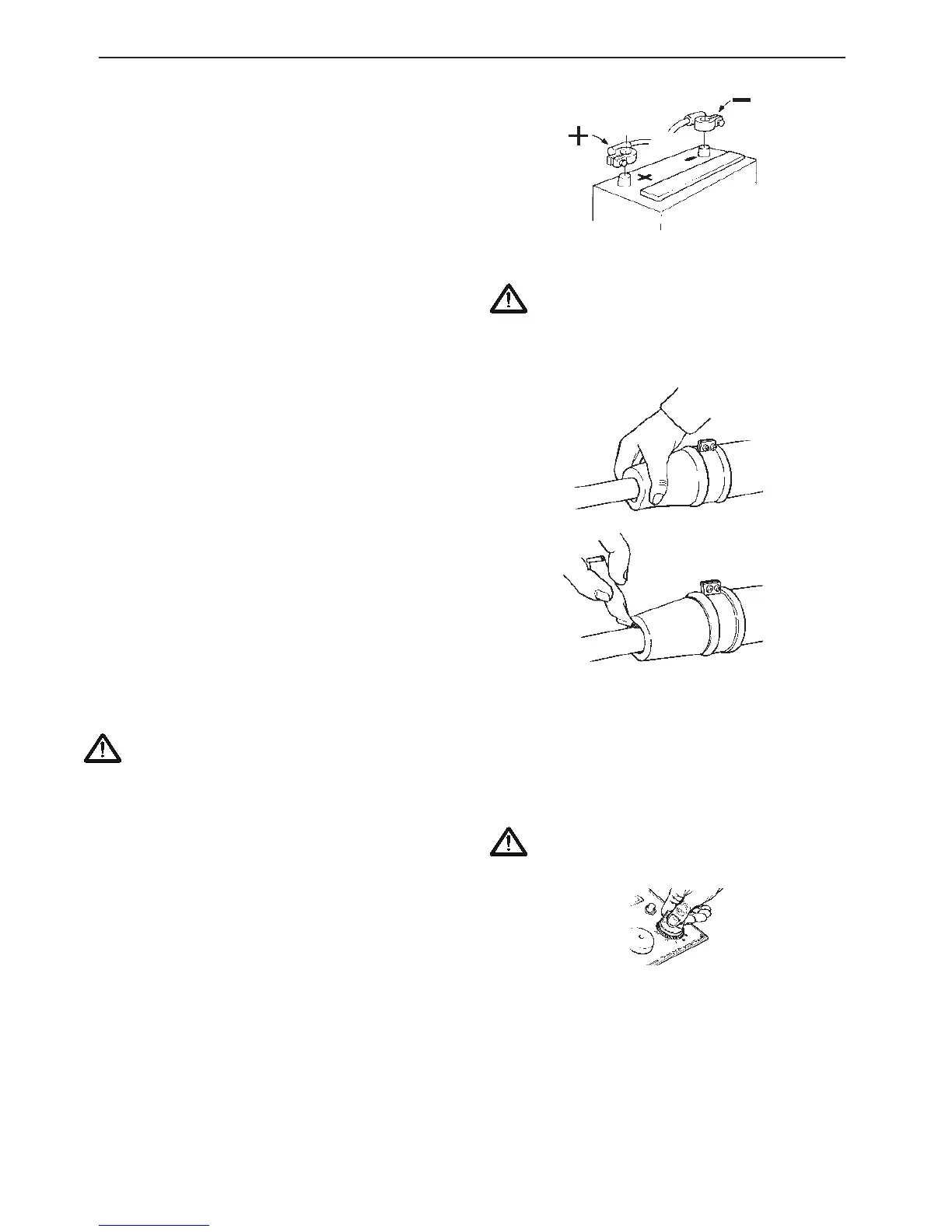

WARNING! Do not paint the zinc anode (zink

ring) in front of the propeller. Leave a 10 mm

(0.4 in) margin without anti-fouling paint around

the S-drive.

Launch the boat when the paint has dried.

*NB. Teflon is a registered trademark of Du Pont.

If the boat is equipped with a propeller shaft seal of

rubber, the following procedure should be observed

after launching:

Vent the tubular sleeve and seal by pressing them

together and pressing the seal down against the shaft

until water emerges. Then press about 1 cm

3

of water

resistant grease into the seal.

WARNING! The propeller shaft seal must be

replaced after 500 hours or 5 years.

Check that the batteries are fully charged. Smear the

terminals with pole grease. Connect the battery cables.

WARNING! Do not reverse the polarity.

Tighten the cable terminals firmly.

Start the engine. Check and make sure there is no

fuel, water and exhaust gas leakage in the boat.

Check also that all steering and control functions are

in order.

When necessary, contact an authorized Volvo Penta

dealer. Let them service your engine and reverse

gear/S-drive according to the instructions given in the

servicing schedule.