Page 27

Section 6

Component Replacement

Section 6Com ponent Replacement

WARNINGS

To prevent serious eye injury, always wear

safe eye protection when you perform vehicle

maintenance or service.

Block the wheels to prevent the vehicle from

moving. Support the vehicle with safety stands.

Do not work under a vehicle supported only by

jacks. Jacks can slip and fall over. Serious personal

injury can result.

The ABS is an electrical system. When you

work on the ABS, take the same precautions that

you must take with any electrical system to avoid

serious personal injury. As with any electrical

system, the danger of electrical shock or sparks

exists that can ignite flammable substances. You

must always disconnect the battery ground cable

before working on the electrical system.

Disconnect power from the ECU/Valve Assembly

before you remove any components. Failure to

disconnect power from the ECU can cause faults

to be recorded and stored in ECU memory.

Use the following procedures to avoid damage to

the electrical system and ABS components.

When welding on an ABS-equipped vehicle is

necessary, disconnect the power connector from

the ECU.

Wheel Speed Sensor

How to Remove a Sensor

1. Follow the vehicle manufacturer's instructions

to back off the slack adjuster and remove the

tire, wheel and drum.

2. Hold the sensor, not the cable, and use a

twisting motion to pull the sensor out of its

mounting block.

3. Remove the spring clip from the

mounting block.

4. Remove any fasteners that hold the sensor

cable to other components.

5. Disconnect the sensor cable from the

extension cable.

How to Install a Sensor

Sensor locations vary according to suspension

types. Typically, a spring suspension has sensors

on the forward axle, and an air suspension has

sensors on the rear axle.

1. Apply a mineral oil-based grease that contains

molydisulfide to the sensor spring clip and to

the body of the sensor. The grease must be

anti-corrosive and contain adhesive properties

that will continuously endure temperatures

from –40° to 300°F (–40° to 150°C).

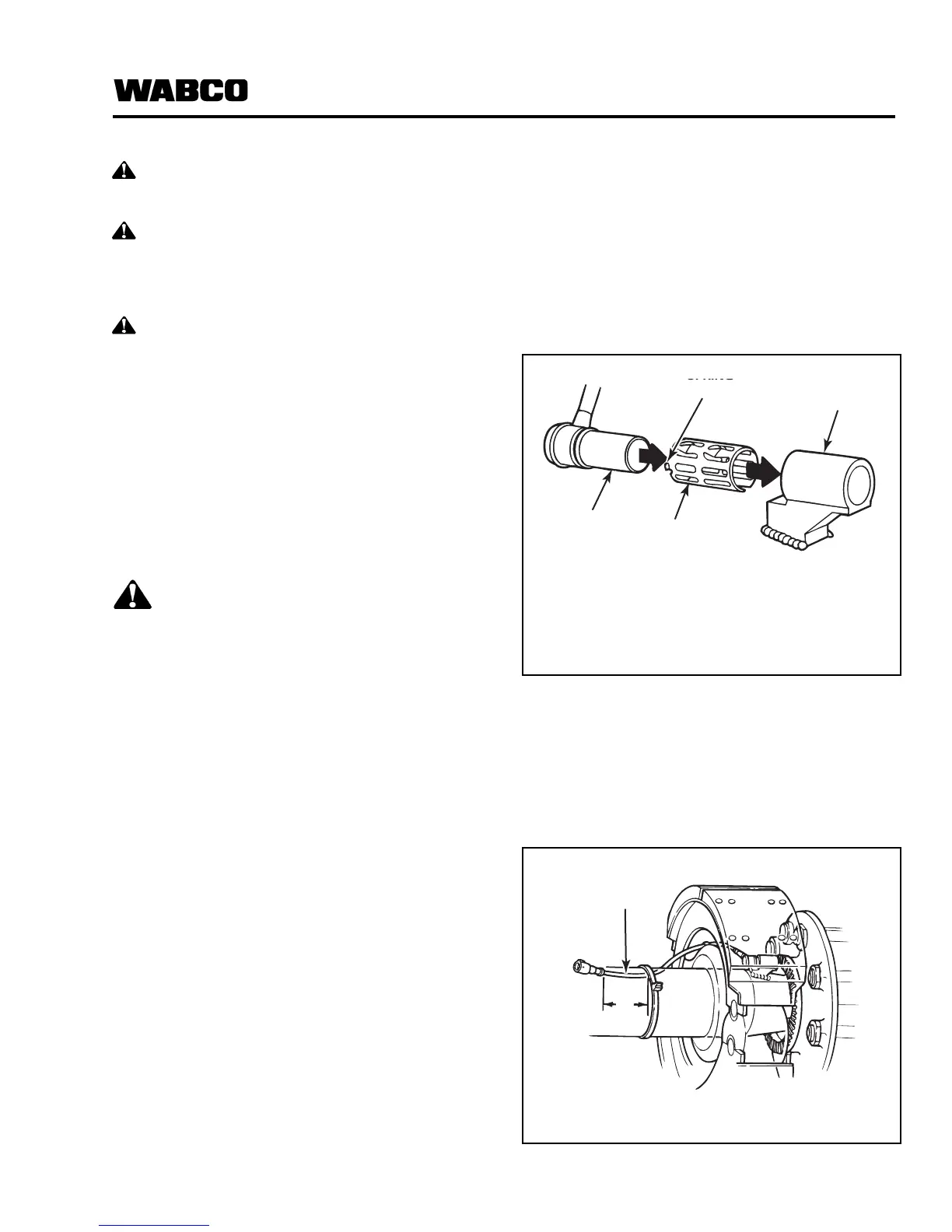

2. Push the spring clip into the sensor holder

from the inboard side, until the spring clip tabs

are against the sensor holder. Push the sensor

into the spring clip as far as possible. Refer to

Figure 6.1 .

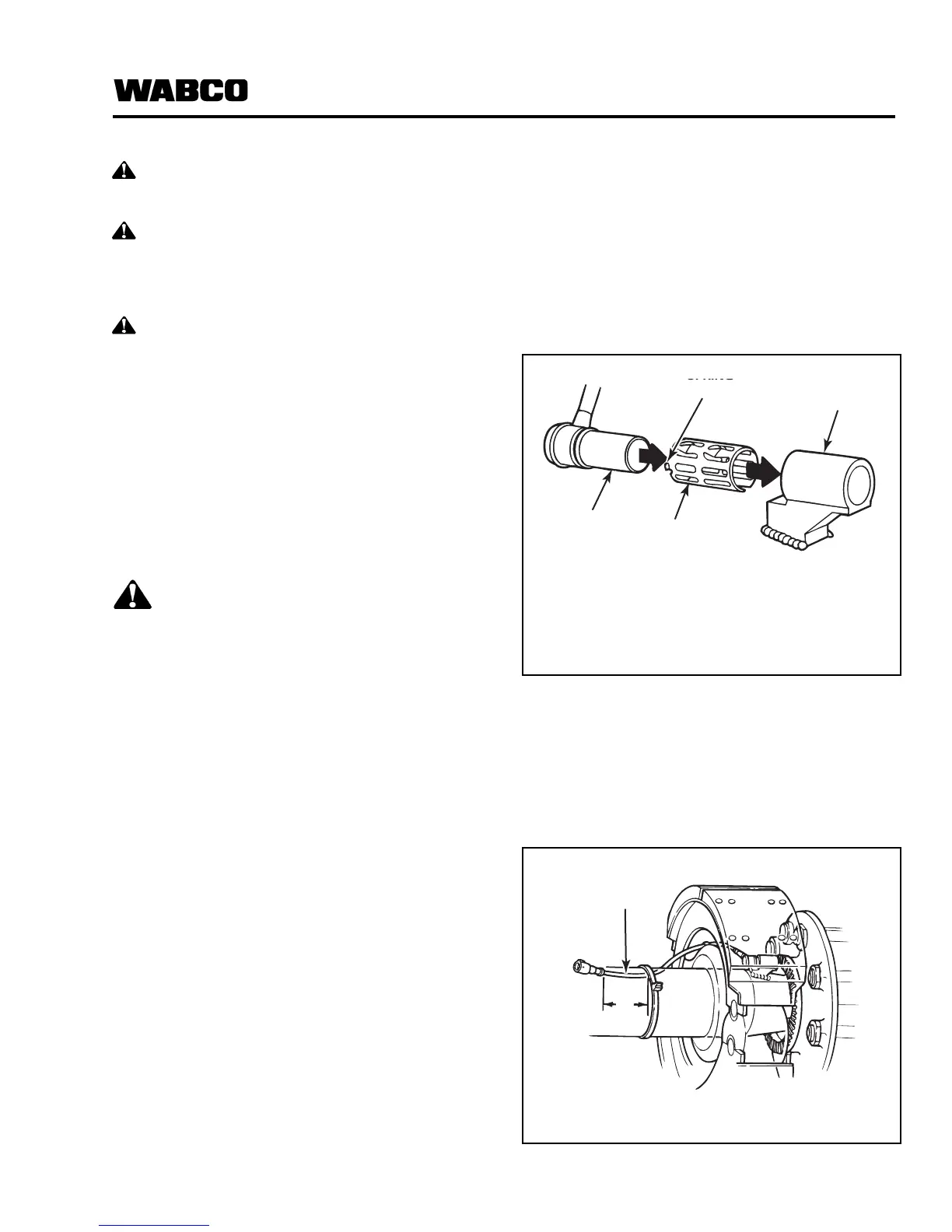

3. Route the sensor cable toward the brake

chamber, over the brake spider, and behind the

axle. Secure the cable to the axle between the

brake spider and the suspension brackets.

Continue to route the sensor cable behind the

spring seats. Secure the cable to the axle one

inch from the molded sensor plug. Refer to

Figure 6.2 .

Figure 6.1

1 Sensor Holder

2 Spring Clip

3 Spring Clip Tab

4 Sensor

Figure 6.2

1 Sensor Cable

SENSOR

HOLDER

SPRING

CLIP

SPRING

CLIP TAB

SENSOR

1002100b

Loading...

Loading...