PS (3-Phase) Series Maintenance

wc_tx000124gb.fm 33

5.4 Troubleshooting

Before ordering repairs, carefully read through this manual, then

repeat the inspection. If the problem remains, contact your nearest

dealer or Wacker representative.

ALWAYS turn off the power before inspecting the pump. Failure to

observe this precaution can result in serious accident.

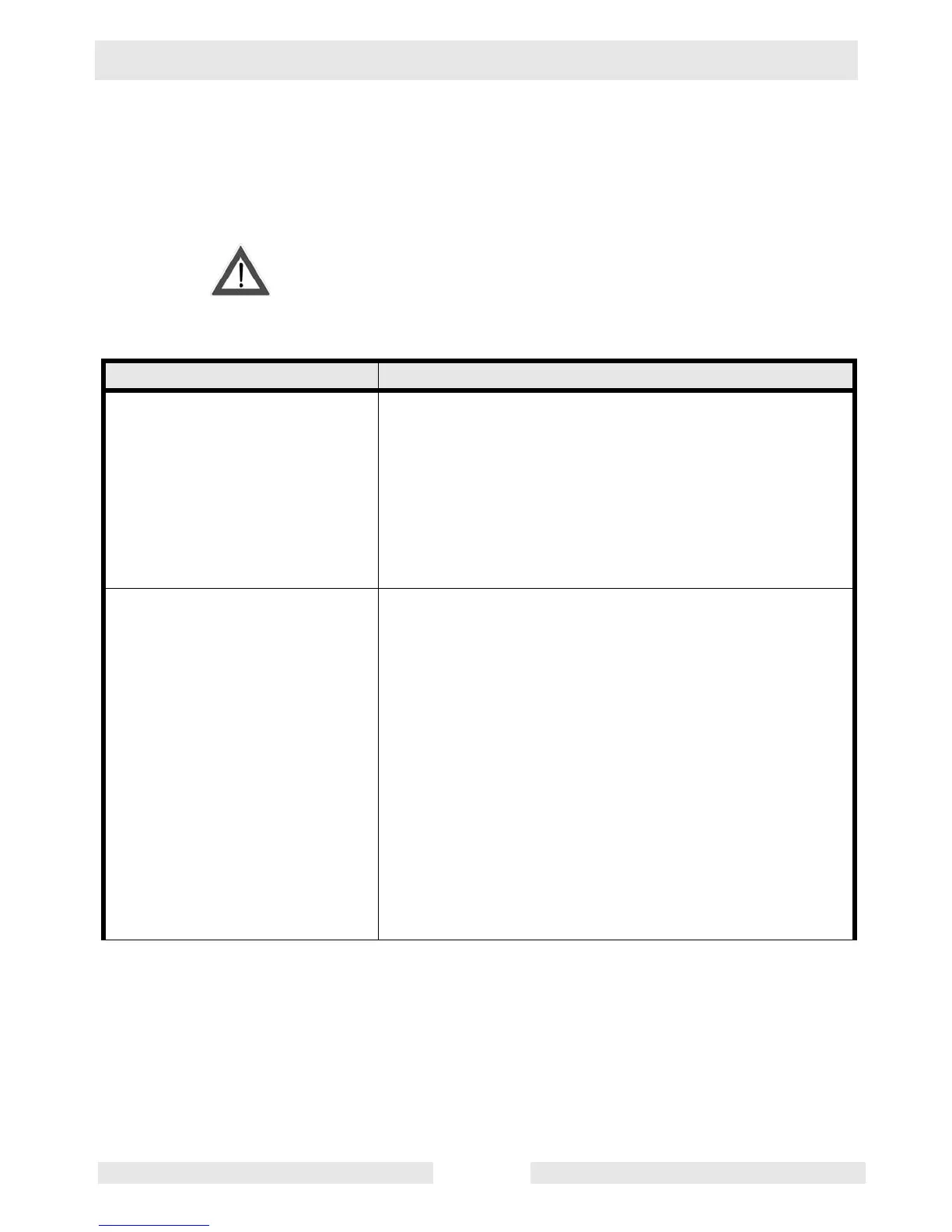

Problem / Symptom Reason / Remedy

Pump fails to start. • No power is supplied (i.e. power outage). Contact

the electric power company or an electrical repair

shop.

• Open circuit or poor connection of the cable assem-

bly. Check if there is an open circuit in the cable

assembly or wiring.

• Impeller is obstructed. Inspect the pump and remove

the obstruction.

Pump starts but stops imme-

diately, causing the motor pro-

tector to actuate.

• Impeller is obstructed. Inspect the pump and remove

the obstruction.

• Voltage drop. Correct the voltage to the rated volt-

age, or use an extension cable that meets the stan-

dard.

• A 50 Hz model is operated at 60 Hz. Check the

nameplate and replace the pump or the impeller.

• The strainer is obstructed, and the pump was oper-

ated dry for long periods. Remove the obstruction.

• Motor abnormal. Repair the motor or replace with a

new motor.

• The pump is picking up too much sediment. Place a

concrete block under the pump to prevent the pump

from picking up sediment.

WARNING

Loading...

Loading...