Mechanical Seal

Inspection

NOTE

All mechanical seals are inspected the same way. PT4 is

shown.

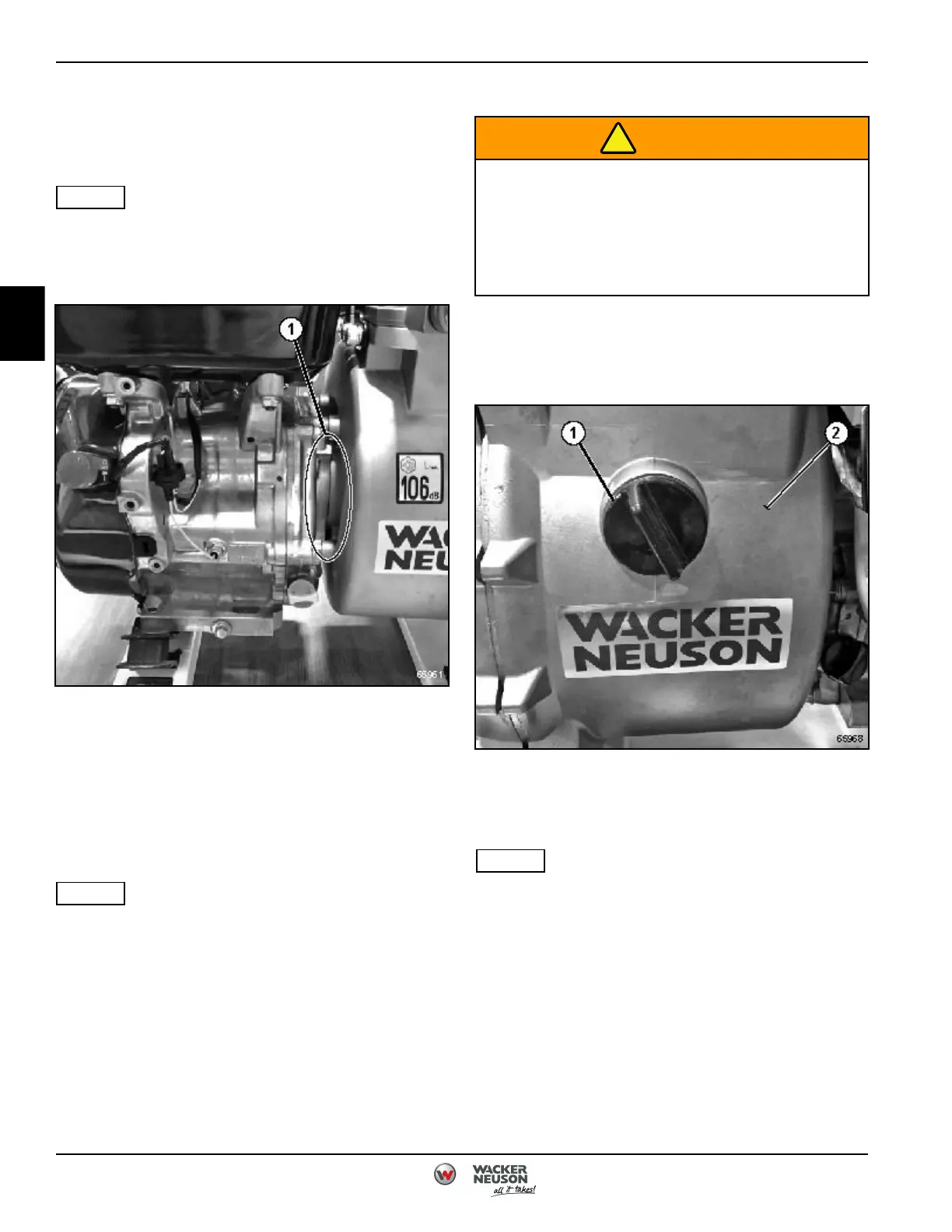

See Figure 2-7.

Figure 2-7: Mechanical Seal Inspection

1. Inspect area between pump casing and engine (1)

for water leaks.

2. If water is leaking between pump casing and

engine, replace the mechanical seal. (See

"Removal and Installation" on page 2-8.)

Removal and Installation

NOTE

All mechanical seals are removed in a similar fashion.

PT4 is shown.

See Figures 2-8 through 2-11.

WARNING

High temperatures and/or pressures may be

caused during priming or operation. If high

temperatures and/or pressure conditions exist,

do not open any plugs or hoses. Failure to

comply may result in injury or death to

personnel.

1. Support pump securely. (See

"Support Pump Securely" on page 7.)

2. Remove front cover. (See

" Front Cover" on page 2-5.)

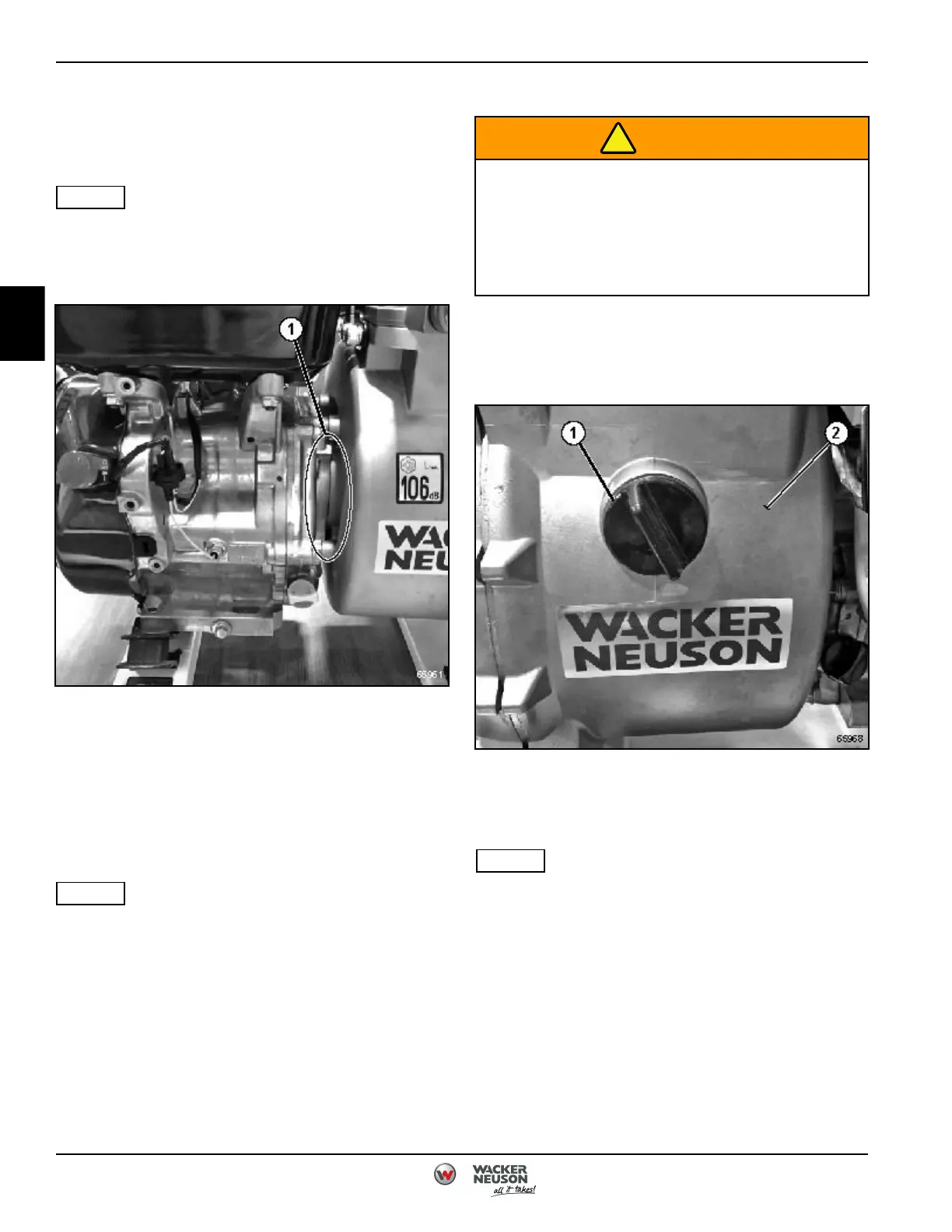

Figure 2-8: Impeller Plug

3. Remove impeller plug (1) from pump (2).

NOTE

If available, an impact wrench can be used to loosen the

impeller on PT3 and PT4 models.

MAINTENANCE

2

2-8 5100048604 (12-18)

Loading...

Loading...