EN

15

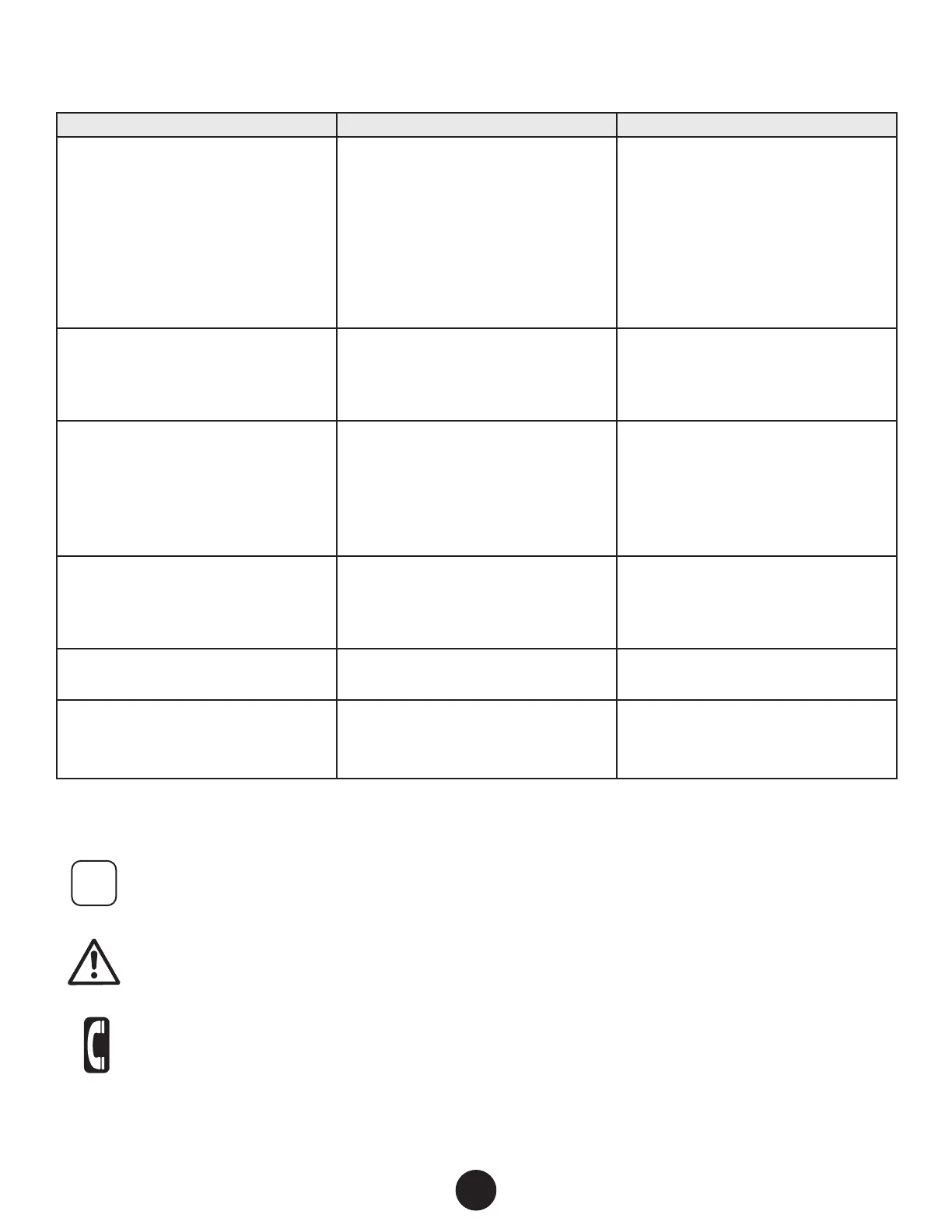

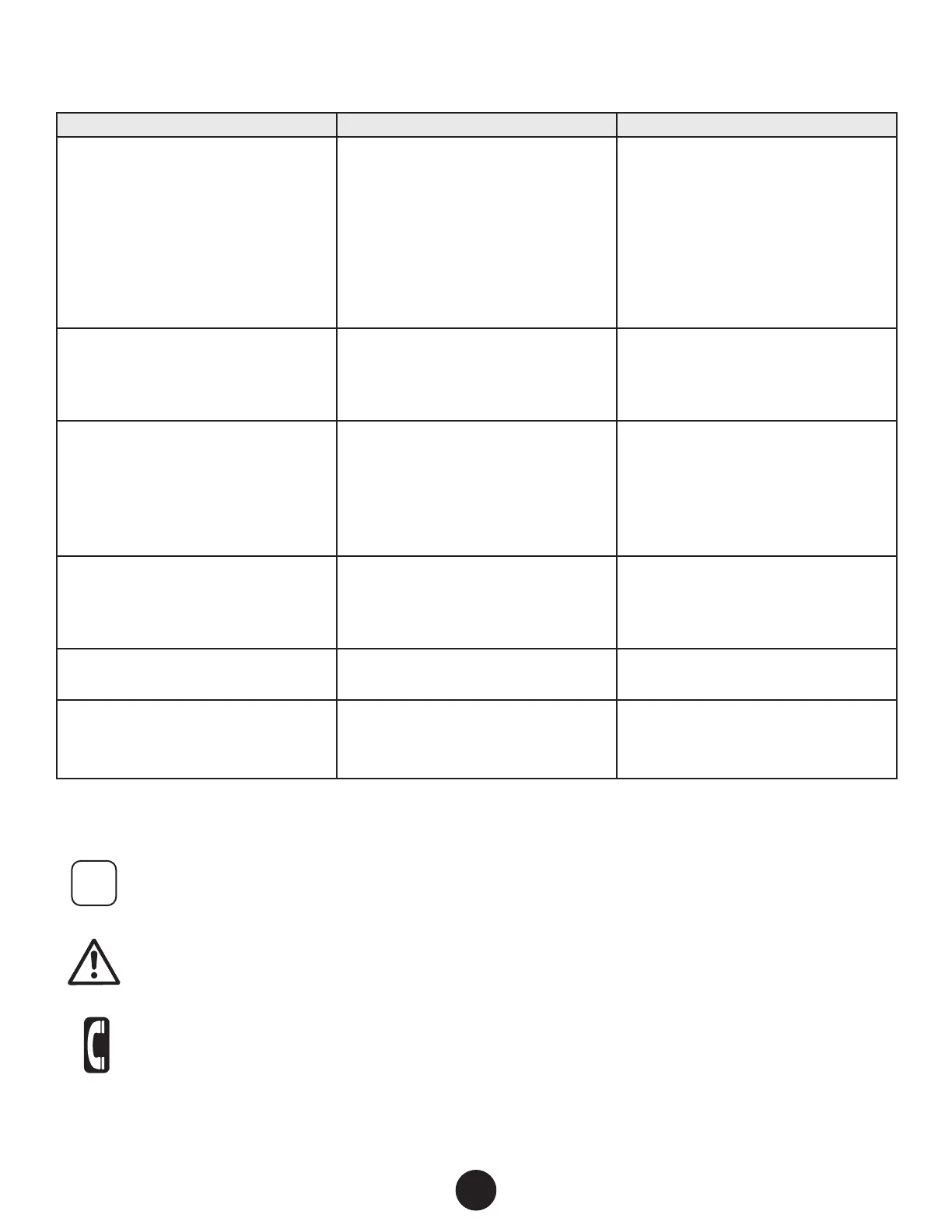

TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

Problem A: Little or no material ow

1. Nozzle clogged.

2. Suction tube clogged.

3. Air vent on suction tube blocked.

4. Material ow setting too low.

5. Suction tube loose.

6. No pressure build up in container.

7. Air valve tube not functioning.

8. Nozzle seal missing.

9. Air lter clogged.

10. Spray material too thick.

1. Clean.

2. Clean.

3. Clean (see page 13)

4. Increase material ow setting.

5. Remove and replace as tightly as possible.

6. Tighten container.

7. Make sure both ends of the tube are

connected and the valve seal is in place.

8. Replace nozzle (iSpray) or nozzle seal

(Detail Finish).

9. Change

10. Thin*.

Problem B: Material leaking

1. Nozzle loose.

2. Nozzle worn.

3. Nozzle seal missing or worn.

4. Material build-up on air cap and nozzle

1. Tighten the retaining ring.

2. Replace.

3. Replace nozzle (iSpray) or nozzle seal

(Detail Finish).

4. Clean.

Problem C: Spray pattern too thick,

runs and sags

1. Material ow setting too high.

2. Air power setting too low.

3. Applying too much material.

4. Nozzle clogged.

5. Air lter clogged.

6. Too little pressure build-up in container.

7. Spray material too thick.

1. Decrease material ow setting.

2. Increase air power setting.

3. Adjust material ow or increase

movement of spray gun.

4. Clean.

5. Change.

6. Tighten container.

7. Thin*.

Problem D: Spray jet pulsates

1. Material in container running out.

2. Air lter clogged.

3. Air valve tube disconnected.

4. Suction tube clogged.

5. Air vent on suction tube blocked.

1. Rell.

2. Change.

3. Reconnect both ends of the air tube.

4. Clean.

5. Clean (see page 13)

Problem E: Too much overspray

1. Gun too far from spray object.

2. Air power setting too high.

1. Reduce distance (6”-8” is ideal).

2. Decrease air power setting.

Problem F: Pattern is very light and

splotchy

1. Moving the spray gun too fast.

2. Material ow setting too low.

3. Air power setting too high.

1. Adjust material ow or decrease

movement of spray gun.

2. Increase material ow setting.

3. Decrease air power setting.

*Thinning the material may be necessary but only after attempting

to achieve optimal spray performance by adjusting the various

controls.

This unit contains no servicable electrical parts. Do not attempt

to service yourself. Store indoors with the cord stored inside the

Power Box.

Have you tried the recommendations above and are still having

problems? In the United States, to speak to a customer service

representative, call our Technical Service at 1-800-328-8251.

See www.wagnerspraytech.com in the “Contact Us” section for

Technical Service hours.

Loading...

Loading...