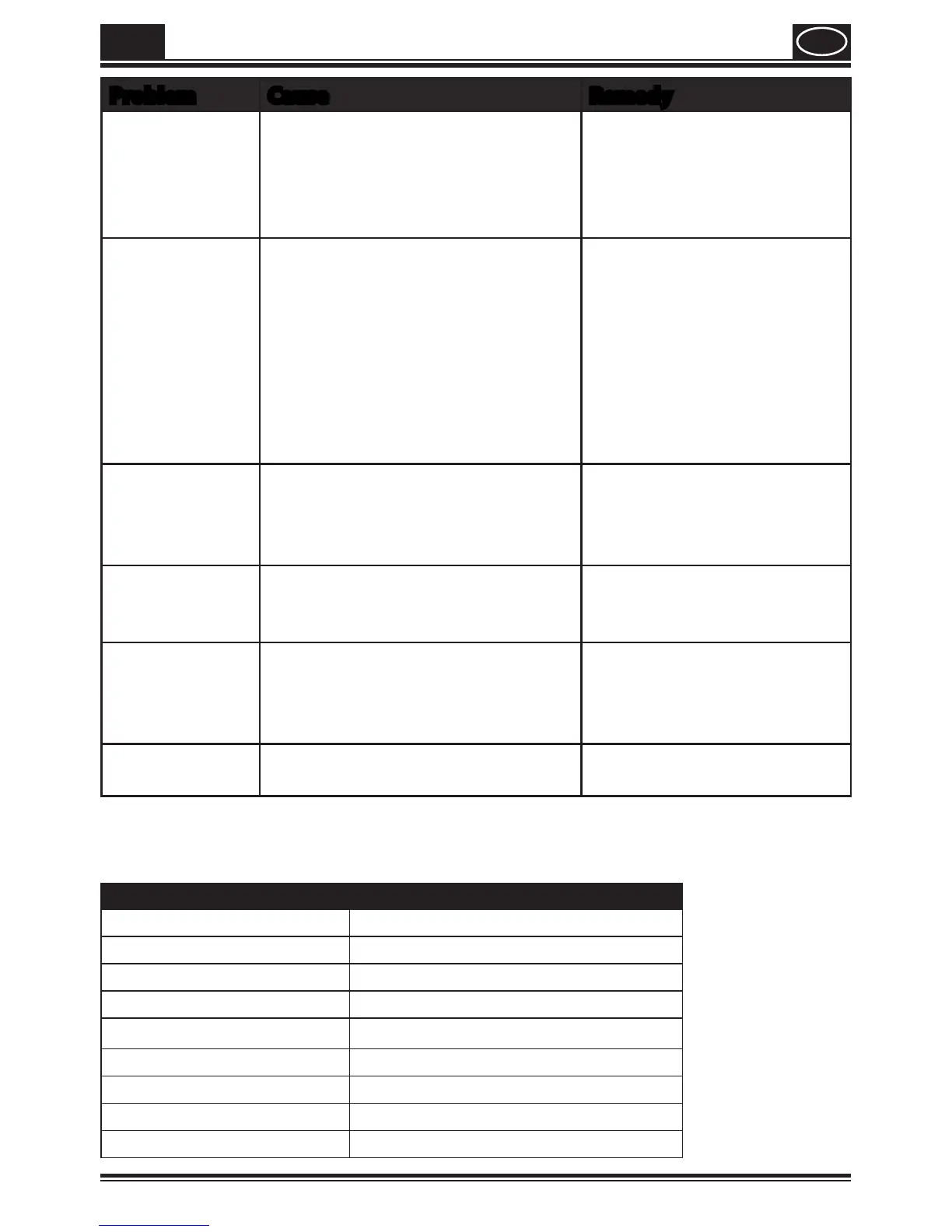

Problem Cause Remedy

Coating

material drips

from the nozzle

•

Nozzle loose

•

Nozzle worn

•

Nozzle seal is missing or worn

•

Coating material assembly at air

cap, nozzle or needle

➞ Tighten

➞ Change

➞ Insert an intact nozzle seal

➞ Clean

Atomisation too

coarse

•

Viscosity of coating material too

high

•

Material volume too large

Material volume adjusting screw

turned too far to the right (+)

•

Nozzle contaminated

•

Air lter heavily soiled

•

Too little pressure build-up in

container

➞ Thin

➞ Turn material volume

adjusting screw to the

left (-)

➞ Clean

➞ Change

➞ Tighten container

Spray jet

pulsates

•

Coating material in container

running out

•

Air lter heavily soiled

•

Nozzle seal is missing or worn

➞ Rell

➞ Change

➞ Insert an intact nozzle seal

Coating

material causes

"paint tears"

•

Too much coating material

applied.

➞ Turn material volume

adjusting screw to the

left (-)

Too much fog of

coating material

(Overspray)

•

Distance to the object too large

•

Too much coating material

applied

➞ Reduce distance

➞ Turn material volume

adjusting screw to the

left (-)

Paint in the

ventilating hose

•

Diaphragm soiled

•

Diaphragm defective

➞ Clean the diaphragm

➞ Replace the diaphragm

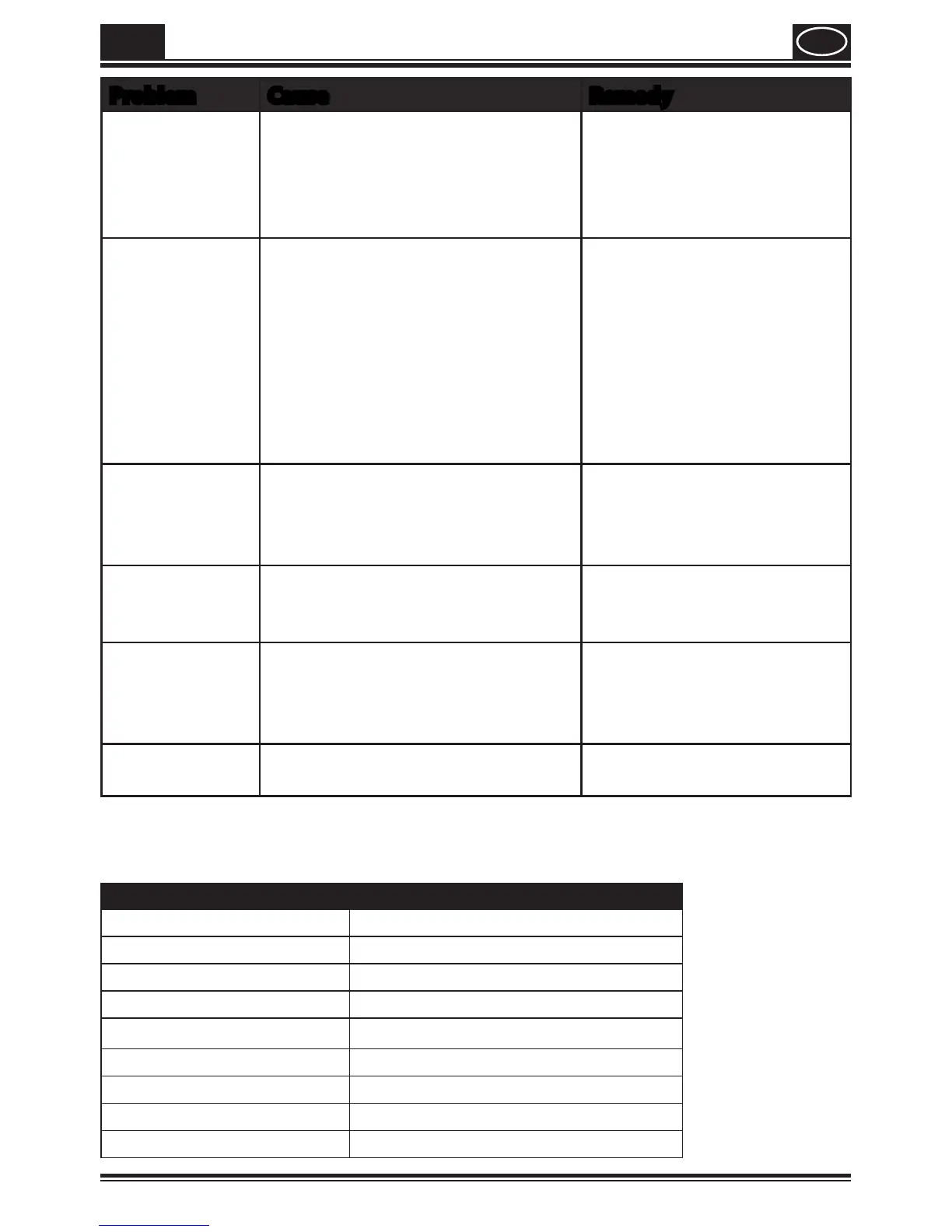

18. Technical Data

Technical Data

Max. viscosity 90 DIN-s

Power source 230 V

~

, 50 Hz

Power consumption 280 W

Atomizing output: 65 W

Protection Class: I

Sound pressure level* 79 dB (A); Uncertainty K = 4 dB

Sound pressure output* 92 dB (A); Uncertainty K = 4 dB

Oscillation level* < 2.5 m/s²; Uncertainty K = 1.5 m/s²

Weight 1,3 kg

Loading...

Loading...